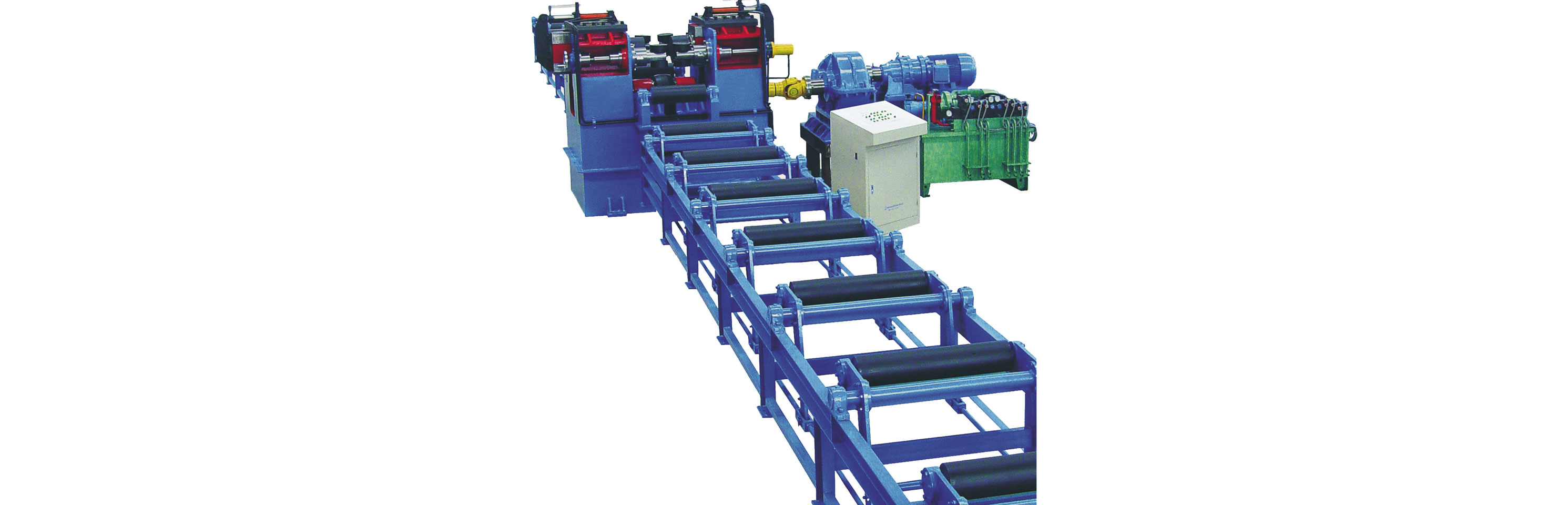

H-Beam Welding Line

H beam machineconsists of an assembling machine, front welding machine, turn-over device, back welding machine and the transmission conveyors. It is used to assemble the H-beam,180°turn-over and transmit, etc. The annual welding capacity is 8000 tons. The Max welding speed can reach about 2m/min.Regularly, we adopt Lincoln welding machine (DC-1000) and NA-5 control system.

JH-150A welding line for H-profile steel is a wonderful technical product that integrates mechanical, electric, and pneumatic technologies. The machine, using advanced technology of single-arc double-wire welding, greatly increases the production efficiency.

The half line and whole line of H-Beam Welding Line Machineare different. The whole production line includes the turnover device and a second welder and it's related roller conveyor, while the half production line doesn't include the above-mentioned parts.

h beam welding line, which is developed by Zhejiang JinggongScience and Technology Co., Ltd., achieves the quality production of H-beam. It's the most advanced H-beam equipment domestically. H-beam welding line consists of the assembling machine, main welder, turnover device, and conveyor, etc.

H beam weldingline is very well received and widely applied by most steel structural enterprises for its high efficiency, big production scope, easy operation, and small space, etc.

Technical Parameter OfH-Beam Welding Line

|

Item |

Parameters |

||

|

H-beam specs |

(mm) Web width |

300-1200 |

300-1500 |

|

(mm)Web thickness |

3-10 |

3-12 |

|

|

(mm)Flange width |

150-500 |

||

|

(mm)Flange thickness |

5-16 |

5-20 |

|

|

(mm) H-beam length |

4000-15000 |

||

|

(kg) H-beam weight |

4000 |

||

|

Inclination of H-beam |

≤15° |

||

|

Total Power |

64KW+90KVA×4 |

||

Size Of Raw Materials Required For H-Beam Welding Line

Web height: 250-1500mm

Web thickness: 3-12mm

Flange width: 150-500mm

Flange thickness: 5-25mm

Length suitable workpiece: 2000~15000mm

Components of H-Beam Welding Line

Assembly Machine

The assembly machine is the first stage before entering the main welder. Before entering the main welder, the web plate and flange plate are to be assembled. By stop welding the two heads of the workpiece, H-beam assembling can be completed to go on the next stage.

Main Welding Machine

The main welding machine is the main equipment for this production line. After the assembled three plates are fed to the main welder through the conveyor, the welding process is started, and through positioning, clamping, and adjustment, until the whole process is completed.

Turnover Device

The turnover device is the assisting equipment of H-beam welding, one side welded H-beam will be transported to turn over device through the conveyor, and to turn over about 180 degrees, and to go on through conveyor to the main welder for welding the other side.

Compared with the traditional welding line, the H-beam welding line has the following seven advantages:

Jinggongis a professionalroll forming machine manufacturer that has many years' experience and a lot of successful cases. Zhejiang Jinggong Science and Technology Co., Ltd.have got many positive reviews regarding thisroll forming machine. If you want to know more, please contact us now!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| PU/PIR Continuous Sandwich Panel Production Line | Continuous pu sandwich panel machine chinaPIR Sandwich Panel Production Line, also called polyurethane sandwich panel manufacturing linemachine, is... | |

| H-Beam Straightening Machine | HBeam StraighteningMachine is mainly used for the angle distortion straightening of heavy H-beam, it adopts hydraulic straightening which will have... | |

| Sandwich Panel Line | continuous sandwich panel lineare widely applied in the protection and decoration of outside wall for tall building and first-class office building... | |

| Steel Structure Machine | Jinggongcan produce various kinds of steel frame machineto match customer's requirements and develop the technology continuously. The main steel s... | |

| Pipe Bending Machine | The CNCChina pipe bending machineis used to make a circle, curve, or spiral for workpieces. It is widely used in such fields as the petroleum indus... |