HYDRAULIC CNC TURRET PUNCHING MACHINE

HYDRAULIC CNC TURRET PUNCHMACHINE

The driving system of the Y30 series cnc hydraulic plate punching machine, with low noise, high speed, and high efficiency, and the thickness of the punching plate is 6mm. The design of high precision and high repetitive positioning accuracy enables the machine to produce more high-precision parts than other similar machines.

Features

adopting worm-wheel and worm mechanism of high precision. the auto-index, whose max. diameter is 88.9mm, can be extended.

Basic Specification

|

Name |

unit |

Parameter |

|||||

|

1 |

Model |

/ |

Y30-A |

Y30-B |

Y30-C |

Y30-D |

|

|

2 |

Workstation |

number |

16 |

24 |

32 |

32 |

|

|

3 |

Punching pressure |

KN(T) |

300(30) |

||||

|

4 |

Punching form |

/ |

Hydraulic drive |

||||

|

5 |

Frame structure |

/ |

Closed bed |

||||

|

6 |

machined sheet metal |

X axis |

mm |

5000(Relocating with one time) |

|||

|

Y axis |

mm |

1250 or 1500 |

|||||

|

7 |

thickness of machined sheet metal |

mm |

<6 |

||||

|

8 |

stamping frequency |

cpm |

<600 |

||||

|

9 |

Pliers number |

only |

3 |

||||

|

10 |

Clamp mechanism |

/ |

Pneumatic |

||||

|

11 |

Repositioning cylinder |

set |

2 |

||||

|

12 |

Control axis number |

individual |

4(X、Y、W、Z) |

||||

|

13 |

Turntable diameter |

mm |

620 |

780 |

900 |

1040 |

|

|

14 |

Mould form |

/ |

Thick turret and long die |

||||

|

15 |

Worktable structure |

/ |

Brush plate and floating universal ball |

||||

|

16 |

Punching accuracy of primary positioning |

mm |

±0.1 |

||||

|

17 |

carrying weight |

Kg |

<150 |

||||

|

18 |

Gas source |

Mpa |

|||||

|

19 |

Total power |

KW |

22 |

||||

|

20 |

speed of sheet movement |

m/min |

<60 |

||||

|

21 |

Rotating tower speed |

r/min |

30 |

||||

|

22 |

Machine weight |

ton |

12 |

||||

|

23 |

Outer size |

mm |

5000*4600*2000 |

||||

Mold distribution

|

B |

C |

D |

||

|

A |

~31.7mm |

~50.8mm |

~88.9mm |

|

|

~12.7mm |

||||

|

16 turret1 |

4 |

8 |

4 |

0 |

|

16 turret2 |

8 |

4 |

2 |

2 |

|

24 turret |

12 |

8 |

2 |

2 |

|

32 turret |

16 |

12 |

2 |

2 |

|

32 turret |

16 |

12 |

2 |

2 |

|

(rotating with 2 B stations) |

Application

It can be applied to punching, drawing and other shapes of holes in sheet metal. It is suitable for processing of batch or sample, reducing mold investment and reducing production cost. It is mainly used in various large and low-level switch cabinets, control panels and air conditioning panels. Box, cabinet, shell, metal furniture, kitchenware, advertising industry.

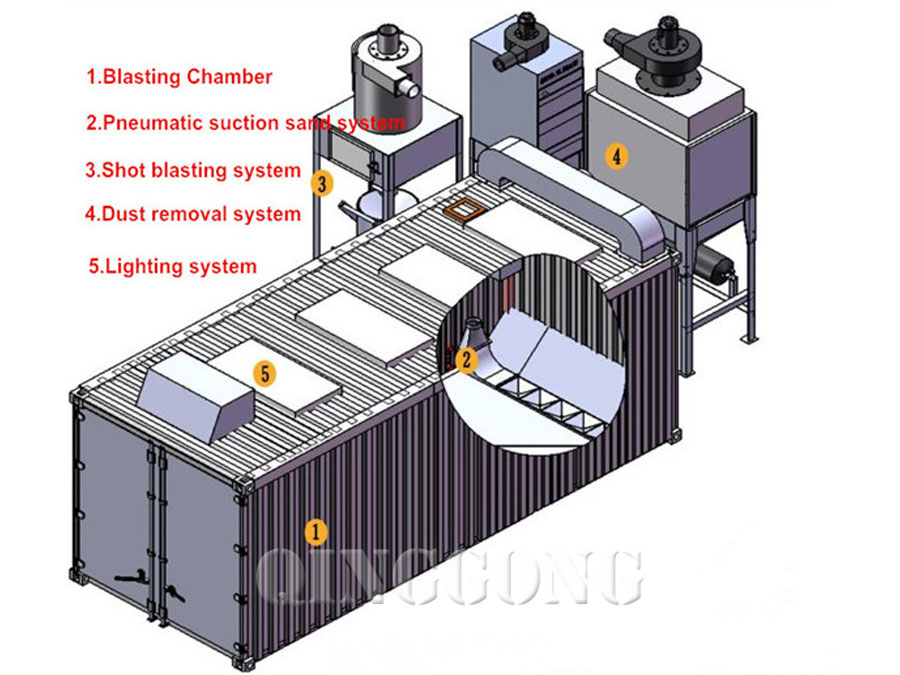

QINGGONG MACHINERYshot blasting machine offers you an effective solution to deal with the surface of the workpieces, including remove the contaminant on the surface, cleaning and roughen a smooth surface before applying a primer or coating to the workpiece. More specifically, the treatment of a shot blasting machine includes derusting, descaling, desanding, or deburring the work pieces. Other uses are such as surface shot peening, finishing, and roughening of surfaces so as to make coat better.

Now the price of roller shot blasting machineis reasonable, anything you need, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| CONTINUOUS TUMBLE PASS-THRU SHOT BLAST MACHINE | The through-feed blast cleaning process offers a number of distinct advantages and ensures efficient and cost-effective blast cleaning. Continuous ... | |

| HYDRAULIC CNC TURRET PUNCHING MACHINE | The driving system of the Y30 series cnc hydraulic punching machine, with low noise, high speed, and high efficiency, and the thickness of the punc... | |

| PAVERS SHOT BLASTING MACHINE | Sandblasting paversshot blasting machine is mainly used for surface roughening treatment of marbles, granites, concrete products, and natural stone... | |

| H BEAM SHOT BLASTING MACHINE | Hbeam shot blasting machineis the most efficient and the most effective process to remove all forms of rust and corrosion materials from h beams pr... | |

| AIR BLAST ROOM | Air blast roomor Air blasting cabinet with pneumatic media reclaim system – An economical alternative, vacuum reclaim systems utilize cyclone... |