Wireless Transmission Pipe Ultrasonic Flaw Detector

The system is suitable for the automatic detection of various internal and external defects of steel pipes. The principle of ultrasonic flaw detection is that after the ultrasonic wave is coupled into the steel pipe through water, the incident propagation will cause ultrasonic reflection when there is a defect in the pipe. The ultrasonic instrument will alarm the ultrasonic reflected signal after realizing the signal to realize the automatic detection of the defect; Ultrasonic pipe testing equipmentis currently the advanced detection equipment in China.

Wireless Transmission Pipe Ultrasonic Flaw Detector Introduction

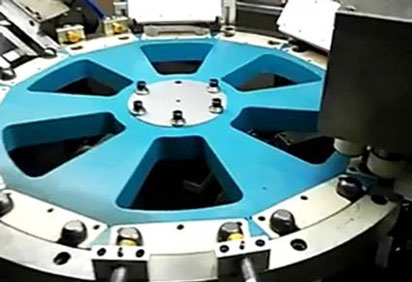

Rotating probe configuration

A total of 3 probe adjustment frames are placed on section 1 at 120°apart. Each of the adjustment frames is equipped with a 2-channel combined ultrasonic line focusing longitudinal probe to detect longitudinal defects of the steel tube in a clockwise direction.

Detection of defects: Vertical and vertical defects in the steel pipe are detected in a clockwise direction.

Center frequency: 5.0MHz±10%

Coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 3 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

A total 3 probe adjustment frames are placed on section2, separated by120°, and a 2-channel combined ultrasonic line focusing longitudinal probe is arranged on each adjustment frame to detect longitudinal defects of the steel pipe counterclockwise.

Detection of defects: counter-clockwise detection of longitudinal defects inside and outside the steel pipe.

the center frequency: 5.0MHz ± 10%

coupling method: water immersion method

Quantity: 3 sets of probes, each consisting of 2 wafers. These 2 sets of probes are evenly distributed in the circumferential direction of the workpiece, spaced 120° apart, on the same section. A total of 6 channels of water immersion probes.

BKNis an eddy current testing benchmark enterprise and has long been committed to the development and production of bearing hardness and crack eddy current screening equipment. If you want to know more details or want a quotation, just feel free to contact us!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Eddy Current Testing Equipment | Are you looking for eddy current equipment for sale? ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagneti... | |

| MFL101 Tank Floor MFL Scanner | Technical Characteristics ofMFL101 Tank Floor MFL Scanner Unique full modular structure, from the main body of the computer mechanism the handle o... | |

| Bolt Vortex Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Eddy Current Testing Equipment | GSET-551 Steel Wire Eddy Current Flaw Detector Brief Using the eddy current signal processing method and high-performance DSP algorithm, the NDT wi... | |

| QTXET-01 Ball Studs Eddy Current Sorting Machine | There are two main types of ball studs: one is a combination of a spherical pin and an integral ball seat, and the other is a combination of a hemi... |

Похожие товары

| Lost Wax Casting Y Piece FlowSplit Fitting | Продавец: Qingtian Baoli Casting Co., Ltd. | Lost Wax Casting Y Piece FlowSplit Fittingis produced through the lost wax casting method, enabli... | |

| Mini Nitrogen Generator | Продавец: 0000 | Mini Nitrogen Generator Mini Nitrogen Generator Are you looking for a reliable, cost-effe... | |

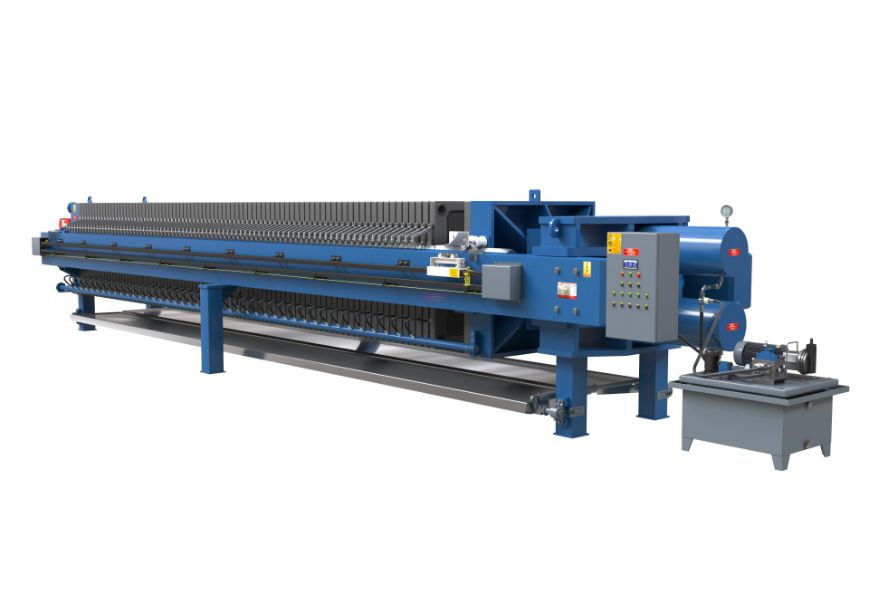

| filter press in chemical industry | Продавец: 00000 | Our for Chemical Industry is designed to meet strict safety and environmental standards, en... | |

| Laser Cutting Service China METAL FINISHING | Продавец: Dalian Zhuosheng Technology Co., Ltd | Laser Cutting Service ChinaMETAL FINISHING Laser Cutting Service ChinaMETAL FINISHING-China Da... | |

| Intake Manifold in Car Engine | Продавец: SDZ AUTO PARTS CO.,LTD | The car intake manifoldis a component of an automobile engine that supplies a mixture of air to d... |