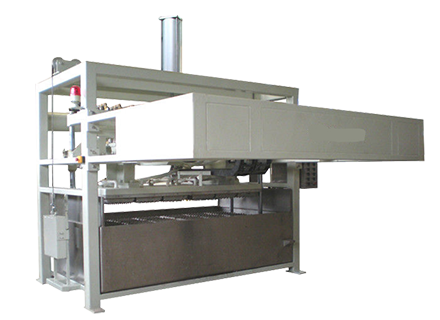

Disposable Food Container Production Line

The disposable food container production line was developed by combining domestic and foreign equipment and advantages. The main electrical components, such as a vacuum pump, PLC, made in Japan and Germany, ensure the reliability of the equipment operation. After heating-vacuum forming-cutting-collecting process, the finished PS foaming sheet can be made into the variety of packaging vessels such as fast food box, aquatic plate, supermarket tray, cake tray, KT board, instant noodle bowl, foam tray etc.

The biggest advantage of this production line is forming cutting and product collection integration, which can increase the production efficiency, reduce the labor cost. The disposable food container making machinehave different machine models which divided according to collection methods, include Slicing type, Stacking type, Robot arm type (the degree of automation is increasing one by one). The customer can choose the machine models and working plate size according to their requirements.

In addition, our disposable food container machinecan also produce different kinds of products at the same time through inserting different samples in one set of mold, this design can reduce the investment in molds, and also can be suitable for examining market demand.

Application of food box making machine

Fruit, vegetable and raw meat trays; food industry and fast food packaging; egg packaging.

Fast food boxes, bowls, trays, and other cutlery.

Medical materials; decorative materials.

Building insulation (wallpaper, filling material and ceiling).

For cold or hot polystyrene containers to hold in cooked food or ice cream.

Polystyrene can be used for printing, easy to stack, waterproof, antibacterial and good insulation.

|

Model |

Unit |

HR-S1080 |

HR-M1080 |

|

Collection method |

Strike |

Mechanical arm |

|

|

Forming area |

MM2 |

1000*750 1000*1100 |

1000*1250 1000*1400 |

|

MM |

100 |

100 |

|

|

Production efficiency |

s/die |

4-5 |

|

|

Forming pressure |

T |

20 |

35 |

|

Installed power |

KW |

170 |

200 |

|

Overall size (L*W*H) |

M |

15*3.5*3 |

15*6*3 |

|

Total weight |

T |

16 |

18 |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Disposable Food Container Production Line | The disposable food container production line was developed by combining the domestic and foreign equipment and advantages. The main electrical com... | |

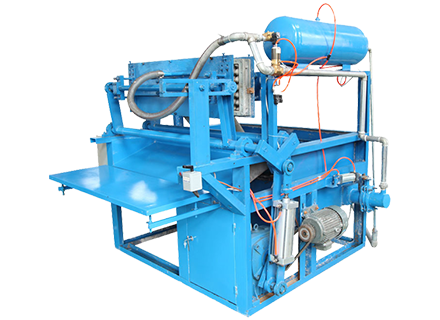

| Manual Egg Carton Production Line | Longkou City Hongrun Packing Machinery Co., Ltd developed the egg carton production line depending on the needs of high-end pulp molded packaging, ... | |

| Pulp Molded Package Production Line | Molded pulp, also named molded pulp or molded fiber, is a packaging material, typically made from recycled paperboard and/or newsprint. It is used ... | |

| Manual Egg Tray Production Line | The manual egg tray production line is suitable for the small-scale investment in egg tray production, such as the small chicken farm, waste cardbo... | |

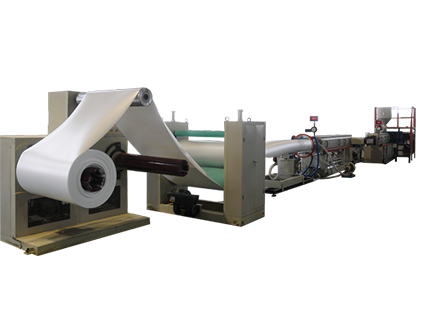

| PS Foam Sheet Extrusion Line | The PS foam sheet extrusion line adopts the twin-screw series high foam sheet production process, and the produced PS foam sheet is a new type of ... |

Похожие товары

| 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System | Продавец: Shenzhen Changing Technology Co., Ltd | 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System ICHES-B is a high-voltage energy s... | |

| 24V 60Ah Lithium-ion Battery for Golf Cart | Продавец: Shenzhen Changing Technology Co., Ltd | 24V 60Ah Lithium-ion Battery for Golf Cart The UT-GC2 Series 24V 60Ah Golf Cart Lithium-ion Batt... | |

| The 332.8V 10kWh (Single Phase) | Продавец: Shenzhen Changing Technology Co., Ltd | The 332.8V 10kWh (Single Phase) Residential Energy Storage Systemis a high-capacity, premium-grad... | |

| 220/230/240V 5kWh - Residential Energy Storage System | Продавец: Shenzhen Changing Technology Co., Ltd | 220/230/240V 5kWh - Residential Energy Storage System The 220/230/240V 5kWh Residential Energy S... | |

| Stationary Valve Core Grinding Bench | Продавец: Metals Kingdom Industry Limited | Stationary Valve Core Grinding Bench is suitable for the valve disks of gate valves and ... |