0.8 Series CCS Round Wire

Origin of new material development

Copper clad steel ground wire:

The material in which the surface of a steel core is uniformly coated with copper includes copper-clad steel bars (for vertical grounding electrode only), copper-clad steel tape, and copper-clad steel wires (including round wires and stranded wires). According to the production process, it can be divided into continuous casting copper-clad steel and electroplating copper-clad steel.

Development of copperclad steel groundingdevice

With the increasing voltage level of power lines and the increasing capacity of the system, higher requirements are put forward for the safety and reliability of grounding devices.

The traditional method in foreign countries is to use pure copper as the grounding material, but pure copper is expensive and it is a strategic resource, which is not suitable for being massively used as grounding devices in China. From 1910 to 1955, National Bureau of Standards (NBS) conducted corrosion resistance studies of grounding bodies. 36,500 samples collected at 128 test sites throughout the United States represented 333 metal materials consisting of iron, non-ferrous metals and protective coatings, respectively. The test results show that only steel bars and stainless steel bars with copper plating thickness over 0.5mm can be accepted.

In addition, continue the statistical data of 8 to 30 years and take the test results of 43 copper samples in different soils, 41 of which were calculated, to get the 0.17mm average pitting depth of 30 years. Therefore, some international standards have determined the thickness of copper coating of copper-clad steel material to be at least 0.25 mm. Considering the hard friction during construction, it is suggested that the thickness of copper coating be defined as 0.5-0.8 mm.

In China, copper clad(copperweld) steel materials are widely used in substation grounding grids in areas with high soil resistivity. Because of the characteristics of UHV project, such as high voltage level, large capacity and short power cut window period, combined with the corrosion intensity of groundwater in the area, copper-clad steel grounding devices have been applied in UHV lines and many UHV lines in China use copper-clad steel materials as grounding bodies.

Comparison between copper-clad steel grounding and traditional hot-dip galvanized steel grounding device

Annual corrosion rate of grounding materials in some place of Beijing and Tianjin

|

Material |

Beijing Liangxiang |

Tianjing Dongli |

|

Stainless stell |

||

|

Pure coper |

||

|

Copper-cald stell |

||

|

Galvanized steel |

The test results show that galvanized steel has the most serious corrosion and its corrosion rate is more than 50 times higher than that of pure copper; the corrosion degree of stainless steel is much lower than that of pure copper and copper-clad steel, showing good corrosion resistance; as a copper-steel composite material, the self-corrosion potential of copper-clad steel in soil is basically the same as that of pure copper, and its corrosion rate is the same as that of pure copper; the corrosion rate of the electroplated copper-clad steel with thinner coating is higher than that of the continuous casting copper-clad steel with thicker coating.

If the conductivity of copper were 100% and the conductivity of standard 1020 steel were only 10.8%, the conductivity of copper would be about 10 times that of steel. However, the conductivity of the 30% conductivity copper-clad round wire would be 30%, and the conductivity of the 40% conductivity copper-clad round wire would be 40%, which would be far better than the steel grounding body. Especially under skin effect, the conductivity of copper-plated strands at high frequencies would be much better than that of steel, that is, the conductivity of copper grounding body would be better than that of steel grounding body. The melting point of copper is 1083℃ and the maximum allowable temperature during short circuit is 450℃ ; the melting point of steel is 1510℃ and the maximum allowable temperature during short circuit is 400℃. Therefore, when the grounding body has the same cross section, the copper-clad steel grounding material has better thermal stability.

According to Appendix D of Technical Conditions for Copper-clad Steel for Grounding in Electrical Engineering, the corrosion rates of copper clad steel in different soils are calculated according to the reference values in table. Corrosion rate of pure copper under different soil corrosion grades (mm/a)

|

Soil corrosion grade |

La extremely weak corrosion |

Lb Weak corrosion |

IIStrong corrosion |

IIIExtremely strong corrosion |

|

Corrosion rate |

The 0.8mm copper plating thickness is enough to meet the requirement of 60 years of service under the grade of III extremely strong corrosion.

The corrosion rate of galvanized steel is nearly 50 times that of copper-clad steel under the same soil conditions, and the grounding body should be overhauled after being used for 3-5 years.

The State Grid has accounted the UHV tower according to the drawings: after the investigation of the market price of material during the construction, the market price of the copper-clad-steel grounding body is calculated at RMB 20 /m, the market price of φ12 galvanized-steel round steel grounding body is calculated at RMB 6 /m and the grounding body laying is calculated according to the grounding construction drawing. During the 30-year whole life cycle, galvanized steel is overhauled every 5 years, of which the cost of material is RMB 20 /m for copper-clad steel and RMB 36/m for galvanized steel, that is, only material cost can be reduced by 80%. Galvanized steel can be overhauled and replaced six times. If the construction cost is RMB 70 /m3 for earthwork and stone works and each base tower is calculated by 23 m3 for excavation, RMB 9660 per base tower will be saved.

Copper-clad steel construction

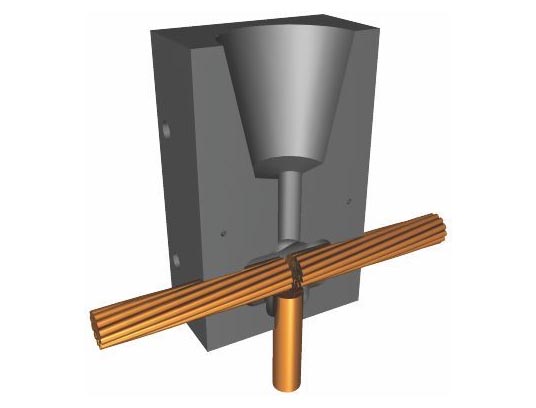

The horizontal laying of the copper-clad steel grounding device is the same as that of the ordinary galvanized round steel, where only the connection method is changed to hot-melt welding, which has reduced the contact resistance between the joints and is more conducive to the release of lightning current.

Exothermic welding, also known as "aluminum heat welding", is a simple, high-efficiency, high-quality metal joining process that has been mass-produced and used in China in recent years. Exothermic welding uses chemical reaction heat of metal compounds as heat source and through superheated (reduced) molten metal or indirect heating, a certain shape and size of the melted joint is formed in the cavity of the special graphite mould, which meets the engineering requirements, and finally through cooling and condensation, the welding process is realized. At present, exothermic welding has generally replaced the mechanical connection between metals in the past.

Advantages of copper-clad steel

Performance parameters of copper-clad steel wire

Copper layer thickness:0.8mm; tensile strength: greater than 500MPa; copper-clad steel bent 180° without peeling off copper layer.

Specification of 0.8mm series copper-clad round steel: Soft copper-clad round bars are generally packaged in hanks or rolls, 100 meters per roll, easy to transport, suitable for laying of large grounding grids and horizontal grounding lines.

Usage:key projects, large grounding grids and horizontal grounding wires in industries with higher lightning protection requirements, etc.

|

Model No. |

Dimeter(mm) |

Copper Layer(mm) |

|

BSD-GW-R10S |

10 |

|

|

BSD-GW-R12S |

12 |

|

|

BSD-GW-R14S |

14 |

Note:

Production method of copper clad steel technical field The invention specifically relates to a production method of copper clad steel.

Background technologycopper clad steel

The conductivity of existing copper clad steel products is not good, far inferior to that of pure copper products. The reason is that the overall product performance is insufficient when copper is coated on steel materials in the process.

Summary of the invention

In view of the above technical problems, the invention provides a production method of copper clad steel.

A copper clad steel production method comprises the following steps:

Preferably, the steel wire surface treatment in step A is a mechanical grinding treatment without water contamination.

The invention provides a production method of copper clad steel. The conductivity of the product obtained by the method is close to that of the pure copper product, the cost is greatly reduced, and the service life is prolonged.

We are one of the leading copperweld copper clad steel wire suppliers, RFQ today!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| BEST Grounding Module | Performance and characteristics of BEST grounding module: The low-resistance grounding module is a non-metallic material-based grounding body compo... | |

| Grounding Conductor | COPPER-CLAD STEEL GROUNDING CONDUCTORS Copper-clad copperweld steel grounding material is a new material developed by Ningbo Zhenhai Beisuda Petroc... | |

| Ground Module | BEST Grounding Module Performance and characteristics of BEST grounding module: The low-resistance grounding module is a non-metallic material-base... | |

| 13579ybj246 | Our zinc-clad steel ground rod, also known as zinc-clad galvanized steel ground rod, also known as zinc plated rod is a new type of grounding produ... | |

| CCS Round Wire | Origin of new material development Copper-clad steel: The material in which the surface of a steel core is uniformly coated with copper includes c... |

Похожие товары

| Yiwu Garment Accessories Wholesale | Продавец: SKYLARK SKYLARK NETWORK CO.,LTD | Yiwu Garment Accessories Wholesale As one of garment accessories suppliers, Skylark Network CO... | |

| Exothermic Welding Products | Продавец: Ningbo Zhenhai Beisuda Petrochemical Equipment Co.,Ltd | What is exothermic welding supplies Exothermic welding, also called hot melt welding, fire-clay ... | |

| Exothermic Welding Mold | Продавец: Ningbo Zhenhai Beisuda Petrochemical Equipment Co.,Ltd | Exothermic Mould/ ExothermicWeld Mold FAQ faqThermit faqHow do you install a lon grounding rod... | |

| Exothermic Welding Flux | Продавец: Ningbo Zhenhai Beisuda Petrochemical Equipment Co.,Ltd | Exothermic Welding Flux Advantages The current-carrying capacity of the welding head surface is... | |

| Copper Bonded Copperweld Ground/Earth Rod | Продавец: Ningbo Zhenhai Beisuda Petrochemical Equipment Co.,Ltd | What is the copper bonded steel ground rod? Product Name: Copper coated copperweld steel china g... |