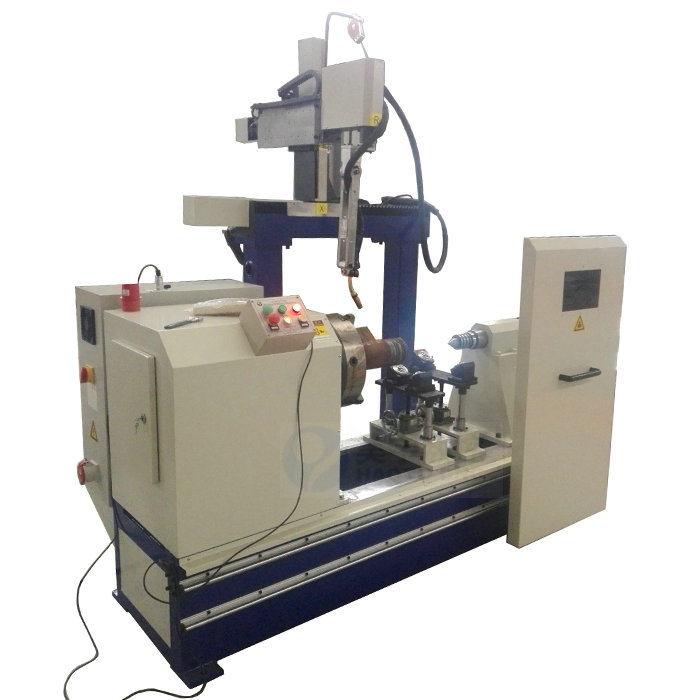

Tank Nozzle and Nut Welding Machine

1. In order to meet welding requirement, welding torch can be adjusted

up and down, side to side and angled turn. They maximize throughout,

and welding deformation can be reduced significantly. Welding seam

detection device will make sure the fixed distance between welding gun

and tank surface.

2. Japan OMRON PLC is used to control the whole machine. With the help of touch man-machine interface, welding mode and specification can be preset,stored and retrieved. There will be fault alarm and indication during welding process, such as stuck wire, blocked wire, etc. Welding original point can be auto-detected. Welding gun will go to mechanical point after finishing the seam.

3. Push-type wire feeder works stably. Machine is with high welding voltage and slow wire feeding performance, which guarantees reliable arc igniting. Machine is also with low welding voltage and low welding current for filling crater.

Другие товары поставщика

|

|

Scaffolding Automatic Welding Machine |

Scaffolding Welding Machine 1. Project Layout It includes 6 sets movable torch mechanism(head),12pcs welding torch, 12pcs wire feeder, 12 sets powe... |

|

|

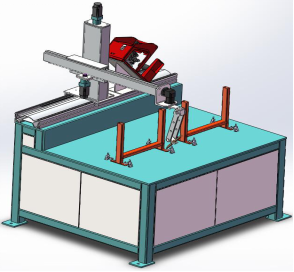

5 axis automatic welding machine |

Used to weld longitudinal and circular seams, also weld for various round nozzle hole and square valve.

CNC control systemand 5axis keypad, weld... |

|

|

pipe flange automatic welding machine |

Flange Welding Machine Application

Circular seam welding machine is used to weld flange and pipe of various sizes

Automatic welding machine al... |

|

|

4 axis welding machine |

4 axes robot Application Welding workpiece: Component name: Wheeler swing arm Product size: min 100mm -max 600mm MIG welding Machine can work conti... |

|

|

Automatic Solar Tank Welding Machine |

Double Circular Seam Welding Machine for Water Heater

Perform the automatic welding for the circular seams on the inner tank of water heater. Ensu... |

Все товары поставщика

Похожие товары