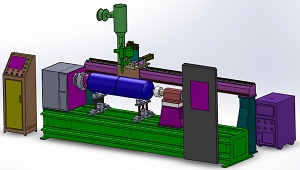

Steel Pipe Welding Machine

1. Welding torch is pneumatically moved in up-down direction. Welding torch can be adjusted up and down, side to side and angled turn. The body of welding torch is ceramic. 2. Japan OMRON PLC is used to control the whole machine. With the help of touch man-machine interface, welding mode and specification can be preset, stored and retrieved. There will be fault alarm and indication during welding process, such as stuck wire, blocked wire, etc. 3. Push-type wire feeder works stably. Machine is with high welding voltage and slow wire feeding performance, which guarantees reliable arc igniting. Machine is also with low welding voltage and low welding current for filling crater.

Другие товары поставщика

|

|

Robot Welding Machine |

Single solder wire MIG welding type. The process of MIG welding is a welding process in which an electric arc forms between a consumable wire elect... |

|

|

Column & Boom Manipulator Welding Machine with Rotating Roller |

1. Structure: 1-base, 2-welding power source, 3-column, 4-boom, 5-column counter, 6-lifting motor, 7-welding oscillator, 8-welding torch and holde... |

|

|

Automatic Lontitudinal Seam Welding Machine |

Automatic Longitudinal Seam Welding Machine Application Machine can weld steel, stainless steel Weld longitudinal seam on tank. Welding process wil... |

|

|

LPG Tank MIG Automatic Welding Machinery |

1.Welding torch can be adjusted up and down, side to side and angled turn. While machine is working, welding gun is fixed, cylinder will rotate. M... |

|

|

4 axis Automatic Welding Machine for Tipper Trailer |

1. 4axis structure, and welding torch is installed in 4axis structure. Workpiece is fixed in the mould, welding torch will rotate. Welding torch w... |

Все товары поставщика

Похожие товары