Rapeseed oil/Canola seeds oil process and rapeseed oil refining equipment

Rapeseed oil/Canola seeds oil process and rapeseed oil refining equipment

(Keywords: Canola Oil Production, Canola Oil Plant, Canola Oil Processing, How Canola Oil Is Made, Canola Oil Production Line, Extracting Canola Oil, Canola Oil Production Line, Canola Oil Mill, Canola Oil Mill Project), Preparation of rapeseed oil use pre-pressing - leaching process mostly.

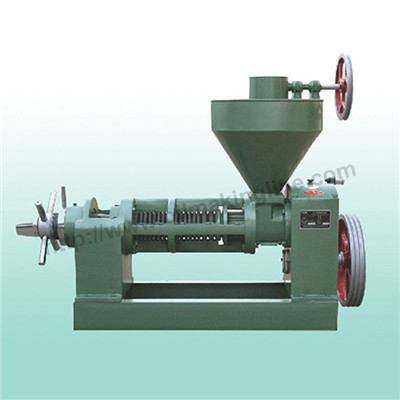

Cooking Oil Preliminary Pressing MachineOperation points:

Rapeseed raw materials using vibrating screen or flat rotary screen screening impurity removal. As rapeseed contains more "side by side mud", also need to use vertical circular screen to the side of the mud to break, sieve out and remove with suction. After cleaning the rapeseed impurities should be less than 0.5%. The newly harvested rapeseed generally do not need to soften, but low water content of rapeseed to be used in softened layer of water in 9%, temperature 50-60 ℃ under softening conditions 12min. Then the use of vertical rolling mill or roller mill to roll the rapeseed into a 0.35mm thickness of the embryo, rapeseed into the rolling mill before the need to use the permanent magnet drum to remove the material contained in the iron. Rapeseed raw embryo by auxiliary steaming wok and pressing steamed frying pan after steaming into the pre-pressing machine mature embryo moisture content of 4-5%, temperature 110 ℃. The pre-squeezed oil is filtered and pre-extracted rapeseed oil is sent for refining. The pre-pressed cake was sent to the leaching plant for leaching. The solvent ratio was 1: (0.8-1). The mixed oil was pretreated, evaporated and stripped to obtain refined rapeseed oil. Leaching wet meal using high-layer steaming machine or vertical high-layer of steam stripping off, the rapeseed meal.

Oil Processing PlantServiceyongsheng

Challenge Maximum uptime while constantly improving your process.

Downtime is a costly business. To keep your operation up and running, a professional partner with the know-how to service your equipment and systems plus a reliable supply of spare parts are essential.

Solution: 24/7 service

Dingzhou Yongsheng Part & Service staff helps optimize and keep your operations on-line throughout the life-time of the equipment.We are trying the shortest delivery time for spare parts ensure .

We take care of your service needs at our workshops or at your mill. Contact us 24/7 for technical assistance or a visit by a field service engineer. Our service include system trouble shooting, retrofits, repairs, hands-on staff training and site audits.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Oil Mill Machine YS - 95 | Oil Mill MachineYS - 95 Name: Oil Mill Machine YS - 95 Packing size: 1630 x 610 x 1250 Power: 7.5 KW Production: 4-5 tons / 24 hours This Oil ... | |

| Corn oil processing Line | Corn oil processing Line (Keywords: Corn Oil Factory, Corn Oil Extraction, Corn Oil Plant, Corn Oil Manufacturing Plant, Corn Oil Production, Corn ... | |

| Oil Press 202-3 | Oil Press202-3 YS-202 preliminary press is a consecutive oil pressing equipment. It’s used in preliminary pressing-solvent extracting press ... | |

| Oil Processing Machine with Filter YS-130A | Oil Processing Machine with FilterYS-130A Name: Oil Processing Machine with Filter Packing size: - Edible Oil Extraction MachinePacking: 2350x84... | |

| Edible Oil Extraction Machine with Filter YS - 95A | Edible Oil Extraction Machine with FilterYS - 95A Name: Edible Oil Extraction Machine with Filter Packing size: - Edible Oil Extraction MachineP... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |