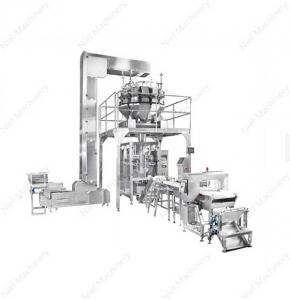

Semi Automatic Weighing and Filling Machine

The weighing and packing machineis mainly designed for ultra-fine powder and high-precision packaging requirements that are easy to dust. It performs two-speed filling, metering and lifting according to the signal given by the weight sensor mounted under the container. It is suitable for packaging milk powder, additives, Toner, dry powder for fire extinguishers, other ultrafine powders, and powders with high precision packaging requirements.

Working Principle of Semi Automatic Weighing and Filling Machine

The semi automatic weigh filling machineis an automatic weighing type filling machine. After the powder material enters the hopper, it is poured into the packaging bag through the screw. The weigh filleris provided with an automatic bag-holding function, which automatically releases after reaching the standard weight, and the whole machine can be controlled by the touch screen. And can pre-store multiple recipes, convenient and efficient.

Application of Semi Automatic Weighing and Filling Machine

Milk powder

Foodstuff

Medicinal

Chicken powder

Cosmetic Pigment

Other industries

Main Features of Semi auto weighing packing machine

(1) The pneumatic bagging device and the bracket are mounted on the weight sensor, and the fast and slow filling according to the preset weight, the weighing system with high reaction speed, ensures high packaging precision;

(2) The servo motor drives the tray to lift and lower, and the lifting speed can be set arbitrarily. When filling, basically no dust is raised to pollute the environment;

(3) Servo motor and servo drive control screw, stable performance, high precision

(4) PLC control, touch screen man-machine interface display, easy to operate;

(5) All stainless steel structure, combined or open type bin, easy to clean

(6) The filling head is equipped with a pistol to adjust the height, and it is easy to realize a variety of specifications.

(7) Fixed screw mounting structure, which does not affect the material properties when filling.

(8) Workflow: manual bagging or manual canning → container rise → rapid filling, while the container is lowered → the weight reaches the pre-value → slow filling → the weight reaches the target value → the container is manually taken out;

(9) Pneumatic bagging device and tow tank device are available for selection, and only need to select different devices to meet the filling and bagging requirements.

(10) Two working modes can be switched, quantitative or real-time weighing, quantitative speed is fast, accuracy is slightly worse, real-time weighing type, high precision, slower speed

Technical Data of Semi Automatic Weighing and Filling Machine

|

Technical Data |

||

|

Model |

NE-5B-1 |

NE-5B-2 |

|

Packing weight |

100g-10kg |

1kg-50kg |

|

Packing accuracy |

100-1000g,≤±2g,≧1000g,≤±0.1-0.2% |

1-20kg,≤±0.1-0.2% ,>20kg≤±0.05-0.1% |

|

Filling speed |

5-20 times/min |

2-8 times/min |

|

Power supply |

3P AC208-415V 50/60Hz |

3P AC208-415V 50/60Hz |

|

Power |

||

|

Total weight |

350kg |

500kg |

|

Dimension |

1135*890*2500mm |

1125 * 975 * 3230mm |

|

Container volume |

70L(Enlarged size 70L) |

100L(Enlarged size 100L) |

Shanghai NIEL MACHINERY Manufacturing Co., Ltd. specializes in the design and production of bulk powder handling equipment and ancillary equipment. Niel Machinery always puts the interests of its customers first, and the company always adheres to the principle of good faith management. If you want to know more details or want a quotation, just feel free to contact us!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Bucket Elevator | Do you want to buy Bucket Elevator? The mini bucket elevatoris suitable for lifting from a low place to a high place. After the material is supplie... | |

| Auger Filler Parts | The screw measuring machine is metered by a screw feeder, that is, the cavity of the screw groove is used as a measuring container, and in each dis... | |

| Post Lifting Bin Mixer | The post lifting bin mixer can automatically complete the functions of lifting, mixing and lowering, and is ideal mixing equipment for the solid pr... | |

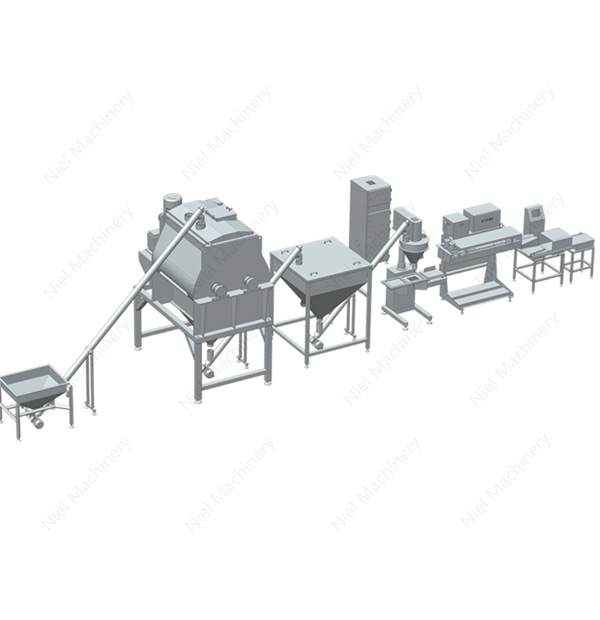

| Powder Mixing And Bag Filling Packing Line | This powder production line is relatively simple in design and is a typical small and medium-sized powder packaging production line. It is suitable... | |

| Powder Mixer Machine | Powder mixer machine is a mechanical device that uniformly mixes two or more materials by mechanical force, gravity, and the like. In the process o... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |