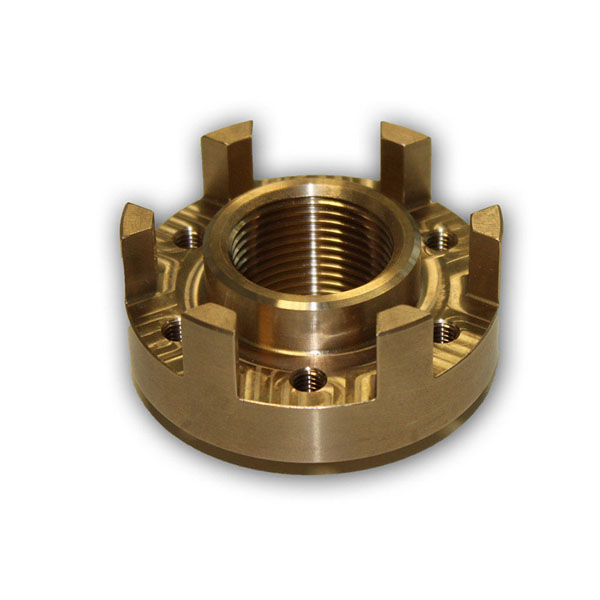

Brass CNC Milling Parts

Basic Info.

Trade Term: EXW,FOB,CIF.CFR

Payment Term: T/T,L/C, Western Union

Delivery Time:7-30days

Place of Origin: Ningbo, China

Information About HEWCHO Brass CNC Milling Parts

Features of brass parts:

·Product name: Brass CNC Milling Parts

·Material:Carbon Steel, Barss, Copper, Stainless Steel, Alumnum, Titanium Alloy

·Machining Tolerances:0.01mm

·Machining Process:

CNC Milling, Drilling, Forging

·Min. Order:500PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

The custom brass fittingshave many advantages such as low price, process performance (e.g., weldability and cold formability) good. We provide brass spare partswhich are of good quality.

Description of our custom brass fittings

Depending on the requirements, brass is mixed with certain alloying elements, such as aluminum or tin. Therefore, brass spare parts have optimum thermal and electrical conductivity, are very resistant to corrosion and have an excellent antibacterial effect. Brass is therefore an important material for mechanical and corrosion-chemically stressed components, which is why the milling of brass in today's manufacturing industry is becoming increasingly important. For example, brass milled parts have become indispensable component components in many industries, such as the fittings, sanitary and food industries.

How is the brass milling done?

In the milling of brass are chosen low cutting speeds in most cases, this act only low cutting forces during machining. For example, brass plates are processed sec with 1.5 mm thickness at a cutting speed of 1.2 mm / 1.5 mm with a router. In addition, should coolant be used as bioethanol or petrol in order to ensure a high surface quality of the components. Many people leave the brass milling small ridges are at the cutting edges, which is why tearing of the cutter avoided and the service life of cutting tools is extended.

Which brass alloys are milled?

Brass has excellent material properties and has therefore become an important construction material. Here, the machinability of lead-free brass for environmental and performance point of view has improved, which is why increasingly beside lead-containing alloys such as CuZn35Pb1, CuZn35Pb2, CuZn38Pb2 CuZn36Pb2As or lead-free alloys are used for milling. So alloys such as CuSn (bronze) and CuNiZn contain (nickel silver) no lead components and therefore just come in sensitive areas for use.

Ningbo Hewcho Industrial is a professional cnc parts manufacturer. We provide CNC Machining Parts, CNC Turning Parts, cold forging partsand so on. Want to know more? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Alloy Steel CNC Machining Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Features of All... | |

| Customized Cold Forging Nuts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Information Abou... | |

| COLD FORGING PARTS | Cold forging Chinais a metal production process of forming technology in which bodies of various shapes are produced from steel blanks, disks or ba... | |

| CNC ENGINEERING SERVICES | CNC Numerical Control milling machine in the CNC engineering servicesis controlled by digitizing signals with an electronic meter. Numerical contr... | |

| Pump Spare Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Pump Spare Parts... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |