Carbon Steel CNC Milling Parts

Ningbo Hewcho Industrial is an ISO:9001 and ISO/TS16949 certified company dedicated to manufacturing superior-quality Precision turned parts Chinaand custom CNCaluminum partsto customer specifications. With a strong focus on continual improvement, our company only utilizes best-practices to ensure that the work we do for our customers is done in the most efficient, precise and cost-effective way possible.

Basic Info.

Trade Term: EXW,FOB,CIF.CFR

Payment Term: T/T,L/C, Western Union

Delivery Time:7-30days

Place of Origin: Ningbo, China

Information About HEWCHO Carbon Steel CNC Milling Parts

Features of carbon steel components:

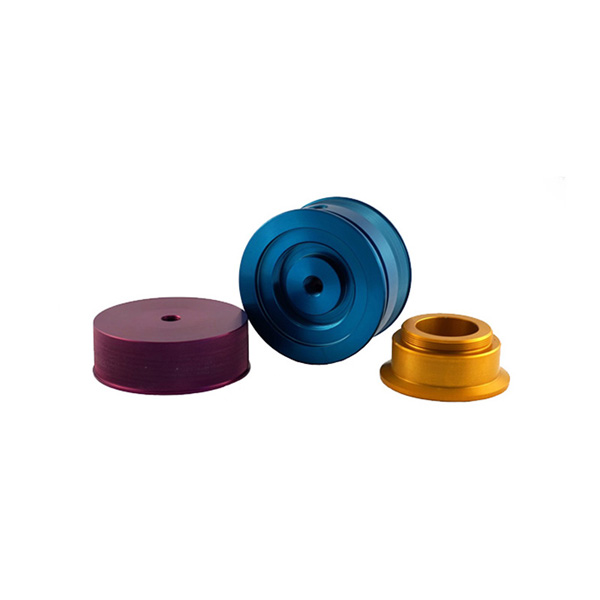

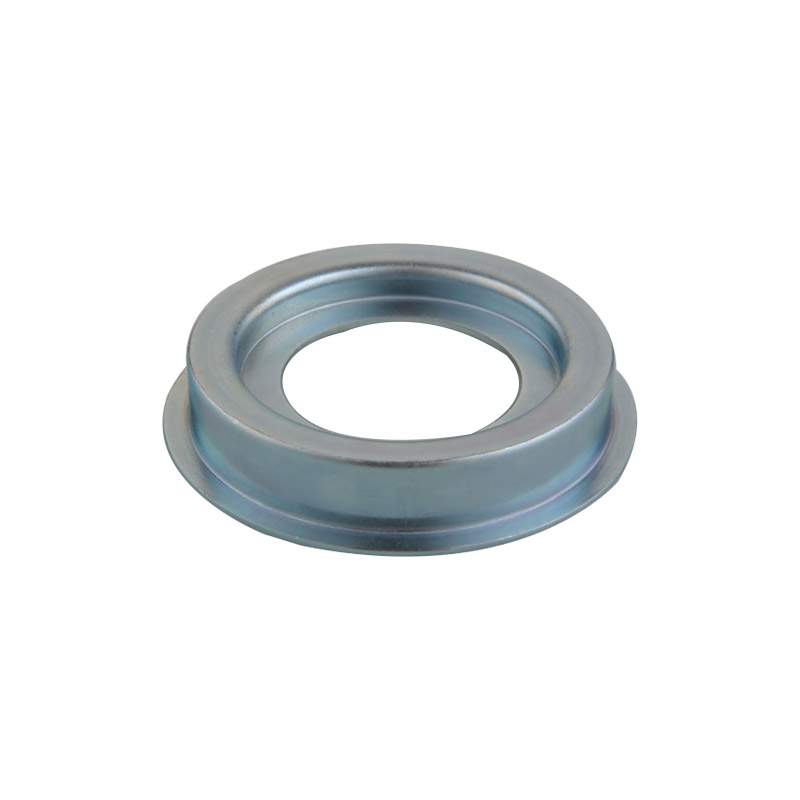

·Product name: Carbon Steel CNC Milling Parts

·Material:Carbon Steel, Barss, Copper, Stainless Steel, Alumnum, Titanium Alloy

·Machining Tolerances:0.01mm

·Machining Process:

CNC Milling, Drilling, Forging

·Min. Order:500PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

As a carbon steel components manufacturer, we provide metal milling service.

|

WhatwecanProvide: |

MachiningMaterial: |

||

|

CNCMachiningService |

CarbonSteel |

||

|

CNCTurningService |

StainlessSteel |

||

|

CNCMillingService |

Aluminum |

||

|

ColdForgingService |

Brass |

||

|

MetalStampingService |

Copper |

||

|

TitaniumAlloy |

|||

|

SurfaceTreatment |

Application: |

||

|

HeatTreatment |

AutomobileSpareParts |

||

|

SandBlasting |

ElectricalApplianceIndustry |

||

|

Polishing |

ElectronicsIndustry |

||

|

ZincPlated |

GeneralIndustry |

||

|

Anodization |

MachineryandEquipment |

||

|

ChemicalFim |

HydraulicandPneumatic |

Description of carbon steel components

Carbon Steel is one of the most widely used materials in machining, which is why milling steel (conventional or automated) has become an indispensable machining process for many steel grades. However, not all steels can be machined without problems since the alloying elements that are added strongly influence the machinability . This can be avoided with the right tool choice and optimally set machine parameters.

What should be considered when milling steel?

When milling carbon steel, users should have appropriate knowledge of materials science in order to select the appropriate tool for the respective steel. Depending on the hardness of the material, the machining process takes place at the lowest processing speeds and using a suitable cooling lubricant (KSS), which is why steel milling minimizes ridge formation on the edges and reduces the applied milling force.

Steel milling is alloy dependent

The machinability of steel depends on the respective alloy components. Chromium, molybdenum, nickel, titanium, and vanadium increase steel hardness and cutting forces, reducing machinability and tool life. Although sulfur and phosphorus favor the machining process with short-brittle shavings, the strength of the steel decreases and there is a risk of built-up edge formation. Manganese favors machinability in steels with a low carbon content. By contrast, steel with a high carbon content becomes harder due to the admixture of manganese, which leads to a deterioration in machining and a shortening of the service life of the milling cutters.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Hydraulic Brake Hose Fittings | Features ofbrake hose fittings: ·Product name:·Material:Carbon Steel·Machining Tolerances:0.05mm·Machining Process:Cold... | |

| Aluminum CNC Machining Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Aluminum CNC Ma... | |

| Alloy Steel CNC Machining Parts | Features ofAlloy Steel CNC MachiningParts: ·Product name:Alloy Steel CNC MachiningParts·Material: Alloy Steel, Titanium Alloy·... | |

| Sheet Metal Stamped Components | Ningbo Hewcho Industrial is a CNC parts manufacturerdedicated to manufacturing superior-quality Precision CNC machined parts and custom metal compo... | |

| Precision CNC Machined Parts | Ningbo Hewcho Industrial is a turned parts manufacturerdedicated to manufacturing superior-quality Precision CNC machined parts and custom metal co... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |