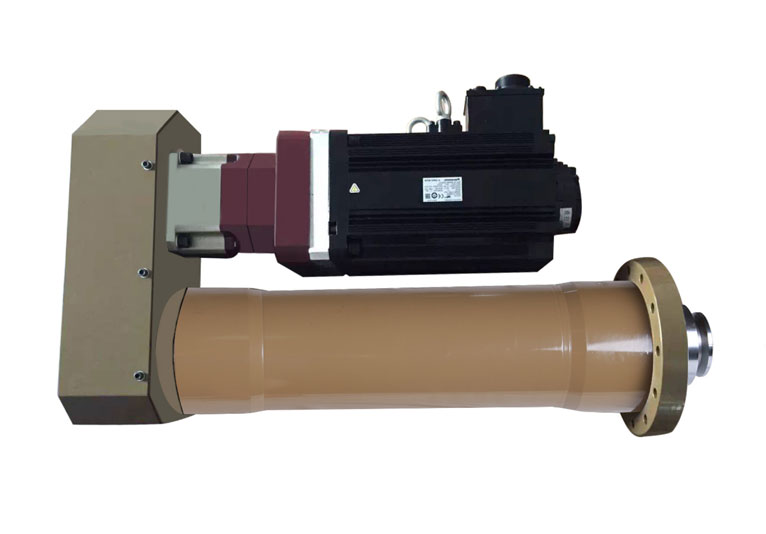

ELECTRIC SERVO PRESS

This is a high-end CNC drilling machine for panel furniture, which has the advantages of high processing efficiency and a high degree of automation. The servo mechanical presscan realize six-side position processing and front and back groove processing at a time.

TY10 series china servo pressis independently developed and designed by Ningbo Tianyu Machinery Equipment Co., Ltd with independent intellectual property rights. It is specially used for the pressing accessories of bearing, shaft sleeve water pump, turbocharger, gearbox, gear, chassis parts, rear axle, and bushing of the subframe shock absorber. Electric servo mechanical press has the advantages of high automation, high precision positioning, energy-saving, environmentally-friendly, simple operation, convenient data storage, and traceability.

Operating Principle Of Electric Servo Press

Electric servo press is called servo pressing or servo press for short. Its working principle is that the high precision ball screw is driven by the servo motor to perform the precision pressure assembly operation. It can realize the closed-loop control of pressing force and pressing depth in the pressure assembly operation to realize the precision pressing of online quality management. In addition, the equipment has the function of online detection, which can draw the real-time force-displacement curve, and avoid unqualified products. Electric servo mechanical press also has the function of audible and visual alarm, and saving and downloading the pressing data.

Product Use Of Electric Servo Press

Suitable for the interference assembly of various parts assembly with the pressing force between 10-100kn, including but not limited to the accessories of precision instruments, electronics, bearing, shaft sleeve, water pump, turbocharger, gearbox, gear, automobile chassis parts, rear axle, and bushing of the subframe shock absorber. The electric servo hydraulic pressis mainly suitable for the tooling being unable to have the hard-limited pressing.

Main Functions Of Electric Servo Press

Pressing mode: positioning pressing; constant pressure pressing; cycle pressing of several parts

Quality control: peak pressure detection; in-place detection; interference fit detection

Data tracking: data networking; data report; data download

Error proofing function: tooling zero-point detection; user account management

Tooling management: product bar code scanning; tooling bar code scanning; user account authority allocation

Product size chart (See attachment: CAD)

Technical parameters (See attachment: CAD)

Industry Pain Points Of Electric Servo Press

Product Advantages Of Electric Servo Press

Based on the roles of various departments of the enterprise and the concept of quality management, the equipment operating system is specially developed and designed by combining the data requirements of Industry 4.0.

The equipment has the function of high-precision positioning, which is especially suitable for the product assembly without positioning devices. The whole machine adopts the high-rigidity design to reduce the positioning errors caused by the deformation of various parts after being stressed.

The curve diagram of the whole process of pressing force and displacement can be displayed on the LCD touch screen, and the whole process control can automatically judge whether the product is qualified at any operation stage, and the unqualified products are 100% removed. And it helps to realize online quality management.

Pressing force, press-in depth, pressing speed, and pressure-holding time can all be easily input on the human-computer interface with a friendly interface.

TY103 can customize, store, and call out 9,999,999 sets of pressing programs. A variety of pressing programs are available to meet the customers’ different requirements.

Through the USB interface or the Ethernet interface, the pressing data can be stored in a U disk or server, ensuring the traceability of product processing data and the control and management of production quality.

As a servo press manufacturer, we also have types of press fit machinefor sale, if you have needs, please contact us, and we will provide you great prices.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| ELECTRIC SERVO PRESS | This is a high-end CNC drilling machine for panel furniture, which has the advantages of high processing efficiency and a high degree of automation... | |

| HIGH TEMPERATURE VACUUM HEAT PRESS | The hot press vacuum pressis used for the test parameters of the material properties, including the fluidity of composite materials, resin fluidity... | |

| TYD TURN-BACK SERIES SERVO ELECTRIC CYLINDER | TYD series servo electric cylinder, compact electric cylinder, fast electric cylinders can work in a harsh environment for a long time without fail... | |

| INTEGRITY/STANDARD REDUCING MACHINE | TY801 reducing series is a kind of mechanical equipment specially developed by Tianyu Machinery for the manufacturers of automobile shock absorber ... | |

| HIGH TEMPERATURE VACUUM HEAT PRESS | Hot press vacuum pressis used for the test parameters of the material properties, including the fluidity of composite materials, resin fluidity, an... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |