CNC Machine Tool Setter System

Tool setter for CNC machining centers is an important operation procedure in CNC machining, and length tool setter's accuracy will directly affect the processing precision of spare parts and efficiency. Pioneer CNC machine tool setters are used for fast and automatic tool setting and tool breakage detection. The automatic cnc mill tool settercan work in harsh conditions in machine tools. Its tool setter probe can improve the accuracy of your workpieces and the productivity of your manufacturing lines, and avoid defective products. Pioneer offers several series of tool setter systems--Radio tool setter system, optical manual tool settersystem, and cable tool setter system.

Types of CNC Automatic Tool SetterSystem

Optical Tool Setter

OTC200 optical tool setter/presetter is a wireless tool setter, optical coded signals are used to transmit information between the tool setter and the receiver.

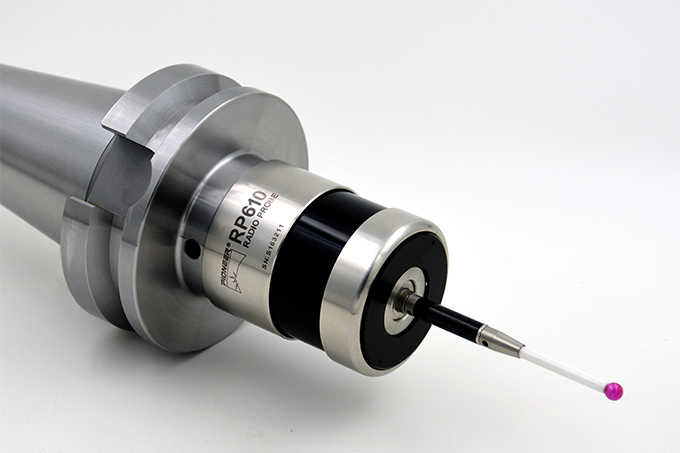

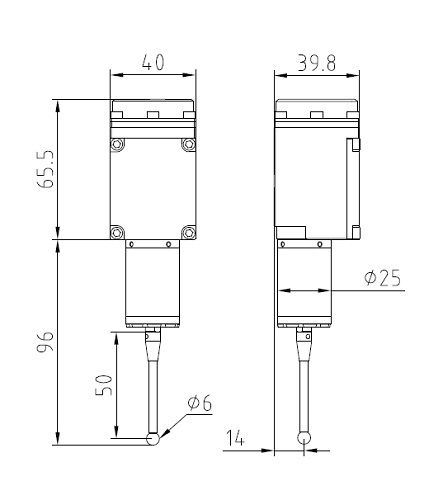

Radio Tool Setter

RP610T radio tool setter is a wireless tool setter, radio coded signals are used to transmit information between the tool setter and the receiver.

Cable Tool Setter System

The cable tool settersystem is suitable for various specifications of machine centers, CNC milling machines, drilling-tapping machine centers, etc. Cable tool setter transmits signal through cable.

Advantages of CNC Machine Tool SetterSystem

1

Measure, correct tool length and diameter offset value quickly and accurately

2

Reduce the manual operation, reduce labor intensity and the influence of human operation factor to the tool setting precision

3

The influence of temperature change on machining precision is controlled by measuring tool parameters

4

Monitor tool wear and tear, reduce rejection rate

FAQs of Tool Setter for CNC Machining Centers

What does a tool setter do?

You can press a button to let the CNC machine tool setter automatically detect the length of the tool (sometimes even the diameter), and then automatically enter the data into the tool table of the controller. All in all, many machines are now equipped with tool setter for CNC machining. Using the tool setter probe to calibrate can avoid measurement errors and greatly improve the accuracy of CNC machining.

Is the tool setter the ultimate tool?

Yes, but it really depends on whether your workshop needs to optimize the cycle time (the time the machine is running) or the setup time (the time the machine is idle).

Is tool setter an important operation in CNC machining?

CNC machine tool setting is the most basic operation in CNC machining. The accuracy of CNC tool setter will affect the machining accuracy of parts. At the same time, the tool setting efficiency also directly affects the processing efficiency. The essence of the tool setter for CNC machining centers is to determine the exact position of the tool tip of different tools in the machining coordinate system.

What's the purpose of tool setting?

When CNC machine tool setter is used for processing, the accurate length and radius of the tool setter are offset relative to the datum, so as to obtain the accurate position of the tool tip of the tool setter. Therefore, the purpose of tool setter is to determine the exact length and radius of tool, so as to determine the exact position of the tool tip in the workpiece coordinate system during processing.

As one of the most professional cnc tool presetter manufacturers,we provide touch probe, cnc measuring probe, tool setting cnc machine, setting tool cnc, spindle probeand etc. Want to know more? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| CNC Machine Probe System in CNC Milling Machine | Harbin Pioneer M&E Technical Development Co, Ltd was founded by Mr. Baichun Sun in 1995. After several years of development, the company gradua... | |

| RPS-20M Radio Probe System | RPS-20M radio probe system contains RP610M touch probe, RSI-20M receiver and standard measuring software. The RP610M is a compact spindle probe wit... | |

| RPS-L11M Radio Probe Systemc | RPS-L11M radio probe system contains TP200 touch probe, RPDM transceiver, RSI-20M receiver and standard measuring software, applied in lathe probe,... | |

| CNC Machine Tool Touch Probe Stylus | As an important component of the probe measurement system, the probe stylus/sensor is mainly composed of three parts: the stylus ball, the stylus r... | |

| TP400 Cable Probe | TP400cable probe system mainly used in various specifications of CNC grinding machines, CNC lathes, and especially measuring devices. TP400 CNC dig... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |