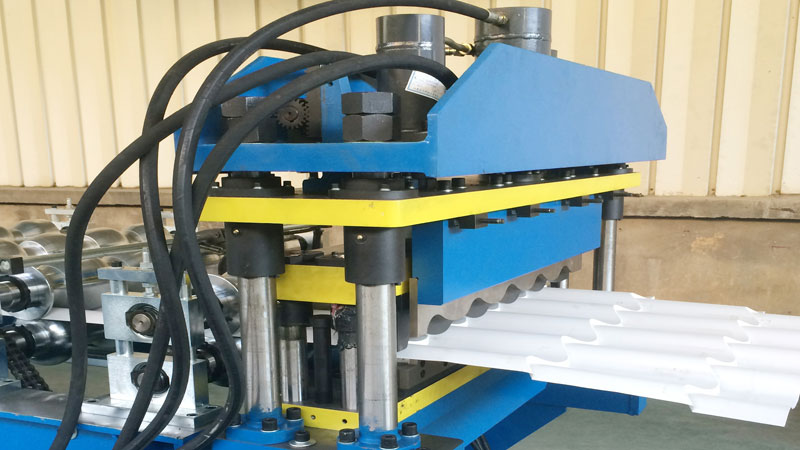

Highway Guardrail & Fence Post Roll Forming Machine

This series ofhighway guardrail machines are equipped with a quick-change machine base formulti-profile purposes. The maximum production speed of ourhighway guardrail machines can reach 20m/min. With the help of this series, about 30-40 tons of barries and 10-12 tons of standing posts can be produced per 8 hours. Moreover, in order to further improve the production speed, devices including ground pit/overground accumulating unit, non-stop hole punching unit, flying tracking cutting, and automatic stacking devices are available for further selections. Prompt delivery is also available.

Suitable Coil Sheet Material forHighway Guardrail Machine

Suitable material Cold/hot Rolled Steel, Galvanized Steel

Barrier Thickness 3.0 (mm)

Post thickness 5.0(mm)

Yield Strength 230-300 (MPa)

Width as profile requests

Production Line Components and Parameters ofHighway Guardrail Machine

1. Decoiler 5t/8t/10t/15t

2. leveling device

3. coil ends butt-welding device

4. underground pit/ over ground accumulating unit optional

5. Servo Feeding Device

6. Holes punching device

7. ground pit/ over ground accumulating unit optional

8. feeding and guiding device

9. Roll forming system 10-30m/min (adjustable)

10. straighter

11. flying cutting device no-stop, tracking

12. Output Automatic Stacker Lateral/Longitudinal (optional)

13. Electric control system MITSUBISH/ SIEMENSE/AMS/Omron (optional or as requested )

Working Flow ofHighway Guardrail Machine

Uncoiler - Leveling device - Cutting coil ends and butt-welding device - Ground pit/ overground accumulating unit - Servo feeding device - Hole punching device - Ground pit/ overground accumulating unit - Feeding and guiding unit - Roll Forming System - Straighter - Flying tracking Cutting to length - OutputAutomatic Stacker

Highway Guardrail Profile Drawings

Finished Panels byHighway Guardrail Machine

Specification ofHighway Guardrail Machine

Machine Condition Fully New, A Grade quality

Panel Shape As profile drawing and customer’s requirements

Operator needed 1-2 people

Power Supply 220V/380V/415V/460V, 50/60Hz, 3P (as requests)

Equipment Weight About 40t

Dimension (L*W*H) about 32*10*2m

LOADING SIZE Normally need 3 x 40' (+1x20’) container.

Equipment Color Normally Blue/White, or as requests;

Place of Origin Zhejiang, China (Mainland)

Packing Standard and careful export packing

As one of the most professional roll forming machine manufacturers china, we provide roll forming equipment, coil upender, fence post roll forming machine, rolling guardrail, pipe milling machine and etc. For more, contact us.

Другие товары поставщика

|

|

Roof/Wall Panel Roll Forming Machine |

Production of roof and wall panel roll forming machinefrom Hangzhou Roll Forming Technology Co., Ltd is dignified and elegant, beautiful and novel,... |

|

|

Double Side Manual Decoiler |

Specifications ofDouble Side Manual Decoiler

Type

Double side

Capacity

2t/2.5t/3t/5t/8t is optional

Extensio... |

|

|

Single Side Manual Decoiler |

SINGLE SIDE MANUAL DECOILER

Specifications ofSingle Side Manual Decoiler

Capacity

2t/2.5t/3t/5t is optional

Extension m... |

|

|

High Speed Roofing Tile Making Machine |

Features and Advantages of High Speed Roof Tile Production Machines

High speed roof tile roll forming machine, is for continuously roll forming an... |

|

|

Downspout Roll Forming Machine |

Downspout roll forming machine, also known as downpipe roll forming machine, downspout elbow machine, roof leader, downcomer, or gutter downpipe ma... |

Все товары поставщика

Похожие товары