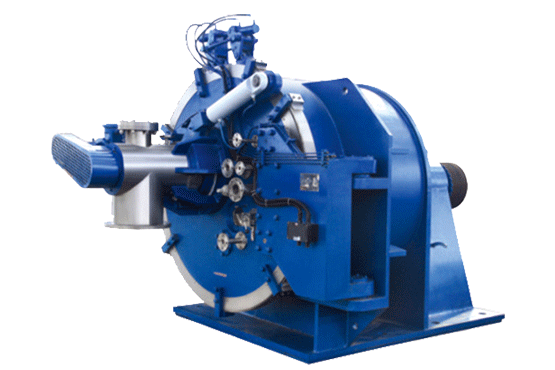

FW INVERTING CENTRIFUGE

When the drum is under high-speed operation, the suspension enters the drum through the feeding pipe. Under the action of centrifugal force, the suspension is evenly distributed in the filter cloth of the drum. The liquid phase passes through the pore of filter cloth, the gap of screen mesh, and the filter hole of the drum and then is discharged from the outlet of the mother liquid pipe; while the solid phase is intercepted to form a ring filter slag layer on the filter mesh. When discharging, the main engine of inverting centrifugefirst slows down to the discharging speed, then starts the discharging motor and pushes the pusher out of the drum. Because the two ends of the filter cloth turn over, and the retained material is turned to the outside of the filter cloth.

FW INVERTING CENTRIFUGE CHARACTERISTICS

FW INVERTING FILTER CENTRIFUGEWORKING PRINCIPLE

After the start-up of the equipment, firstly judge whether the proximity switch of the motor end is effective or not. If not effective, the assist motor will work to seal the drum. After that, the assist motor will stop and the main motor start to run. After the drum reaches the set speed, the feeding valve will open and suspension will enter into the full-speed rotary drum filtration through the feeding pipe. Under centrifugal force, the solid of the suspension will be distributed evenly on the internal surface of the filter mesh and most of the liquid will pass through the small holes on the filter mesh and drum wall and be drained outside through the liquid outlet. After a long time operation, the thickness of the solid product inside the drum will keep gaining. When reaching the set time, the feeding valve will close automatically. (feeding time will be changed for different products and can be adjusted at first commissioning).

FW Performance and Use

FW series are inverting filter centrifuges with intermittent feeding and intermittent discharging.

Feeding, separating, washing, dehydration, and other operating procedures are completed under full speed; discharging is completed under the condition of deceleration, which avoids material contact with subject other than equipment, and can protect the operator and material from pollution as well.

The machine meets GMP specifications and is suitable for filtration and separation in pharmaceutical, food, and chemical industries

Saideli, as an excellent industrial centrifuge machine manufacturer, offers a wide range of industrial centrifuge machinefor you to choose from.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| GKH AUTOMATIC SIPHON HORIZONTAL SCRAPER CENTRIFUGE | This screen centrifuge is controlled by PLC and regulates the speed by frequency convertor. The braking system of continuous centrifuge applies dyn... | |

| CONTINUOUS ROTARY VACUUM DRUM FILTER | YG Rotary Continuous Drum Filter can be used to quickly carry out solid-liquid separation of various suspension materials with such features as con... | |

| SAIDELI-INDUSTRIAL CENTRIFUGE SEPARATOR MACHINE MANUFACTURER | Jiangsu Saideli, an industrial centrifuge machine manufacturer, continuously develops high-tech and top-quality products which include industrial c... | |

| LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE | LLGZ PULL BAG SCRAPER BOTTOM DISCHARGE CENTRIFUGE L(P)LGZ vertical basket centrifuges are suitable for solid-liquid separation of fibroid products... | |

| GKF AUTOMATIC HORIZONTAL SCRAPER CENTRIFUGE | Saideli GK(F) series automatic scraper centrifuge is mainly used in solid-liquid separation of raw materials, intermediates and end products in the... |

Похожие товары

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |