Overflow Ball Mill

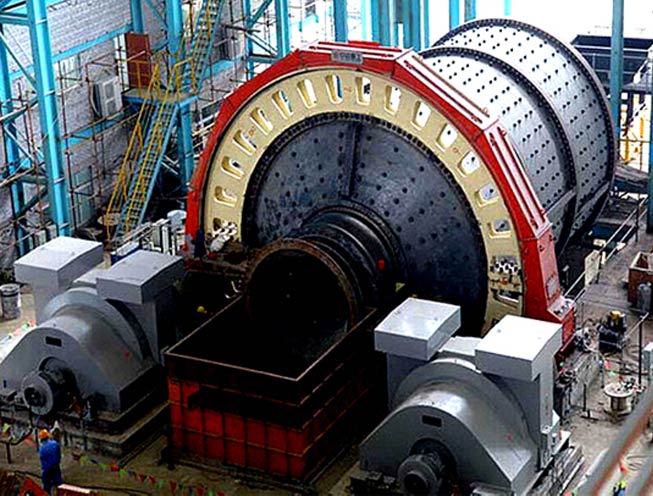

In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow type ball millis the most widely used equipment in wet grinding. Overflow ball millis mainly used for wet ball mill. In the grinding process, raw materials and water are added at the same time to make the ground fine materials form pulp with water, which is discharged in the way of self flow, so as to complete the industrial grinding mill operation, so it is called an overflow mill.

Features of Overflow Mill

lOverflow mill is easy to start, stable operation

lSimple structure, convenient maintenance

lVarious working modes and optional granularity

lThe grinding time is short and the service life is long

Application of Overflow Ball Mill

Overflow ball mill is often used for grinding fine ore or regrinding concentrate in mineral processing industry, such as cement ball mill. In addition, it can also be used in silicate products, building materials, chemical fertilizers, non-ferrous metals, glass ceramics and other production industries.

Working Principle of Overflow Ball Mill

When overflow mill is working, raw materials and water are continuously added from one port, and the slurry is formed after being ground by steel ball inside the cylinder. After the slurry is ground to the target size and accumulated to a certain height, it will overflow from the other end.

Advantages of Overflow Ball Mill

Intelligent Grinding Expert System-Ball Mill

To realize the intelligent control for ball mill operation, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient.

Spare Parts & Services of Overflow Ball Mill

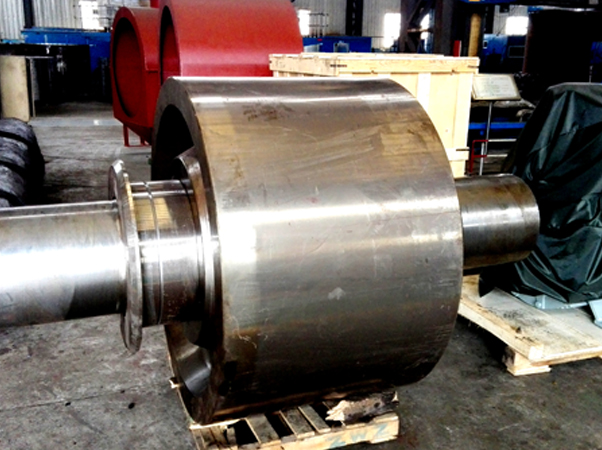

Grinding Mill Parts

Customized and matched mill parts and components (including end cover, shell, hollow shaft, liner, main bearing, girth gear, pinion, and gear) designed to improve heavy equipment machinery reliability. From component suppliers to full-service partners, CIC can support you no matter what brand of mill you are making.

Mill Liners

We have the most complete range of mill liner products in the market and we can provide you with the best solution to meet the specific needs of the mill, which make your mill out of the ordinary.

Grinding Service

Whether you want to minimize maintenance downtime, increase production and reduce tonnage costs, or improve efficiency, we are here to support you.

There are many heavy machinery companies, but we are one of the best choices for you.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Supporting Roller | CIC is a more than 30 years manufacturer and reputed supplier of support roller used in rotary kilns, rotary type driers and so on. CIC has been sp... | |

| Dry Ball Mill | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and othe... | |

| Wet Grid Ball Mill | Wet Grid Ball Mill Wet ball millis a kind of energy-saving industrial grinding mill which adopts rolling bearings and has high efficiency. Wet gri... | |

| Calcium Carbide Furnace Tap Hole Machine | Dig furnace robot arm control has a walking mechanism, multi-station operator, hydraulic, electronic control, and other components. The operation i... | |

| Supporting Roller | CIC is a more than 30 years manufacturer and reputed supplier of support roller used in rotary kilns, rotary type driers and so on. CIC has been sp... |

Похожие товары

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |