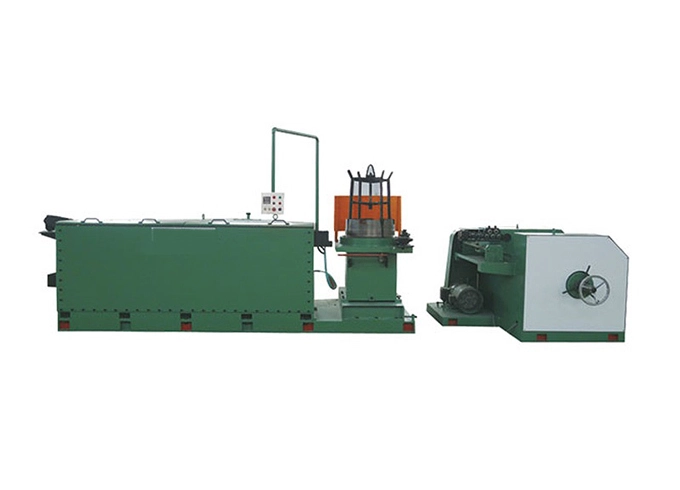

2 Spindle Nut Tapping Machine

2 Spindle Nut Tapping Machine

The 2 spindle nut tapping machine is designed for high-speed and efficient tapping of nuts. With its two spindles, it allows for simultaneous tapping operations, effectively reducing cycle times and increasing productivity. This machine is built with precision and durability to ensure accurate and consistent tapping results. It is suitable for manufacturers looking for improved efficiency in nut production.

Specifications of 2 Spindle Nut Tapping Machine

|

Model |

Size |

Productivity |

Main Motor(kw) |

Motor of Material |

Oil Pump |

Air Pressure |

Dimension |

Weight |

||

|

Spindle |

(pcs/min.) |

Mixing (kw) |

(kw) |

(kg/cm) |

(LxWxH/mm) |

(kg) |

||||

|

Flange |

Hex |

|||||||||

|

LDH-M4-2 |

M3 |

2 |

80 |

100 |

1100x1100x1800 |

450 |

||||

|

M4 |

2 |

80 |

100 |

|||||||

|

LDH-M8-2 |

M5 |

2 |

70 |

100 |

2-3 |

1100x1100x1800 |

450、500 |

|||

|

M6 |

2 |

65 |

90 |

|||||||

|

M8 |

2 |

60 |

80 |

|||||||

|

LDH-M12-2 |

M10 |

2 |

50 |

70 |

3-4 |

1100x1100x1800 |

500 |

|||

|

M12 |

2 |

45 |

60 |

|||||||

|

LDH-M16-2 |

M14 |

2 |

40 |

50 |

3-5 |

1100x1100x1800 |

550 |

|||

|

M16 |

2 |

30 |

40 |

|||||||

All specifications are subject to changes without prior notice.

Features of 2 Spindle Nut Tapping Machine

A 2 Spindle Nut Tapping Machine is designed for tapping operations, typically used in manufacturing processes for producing threaded holes in various materials. Here are five key features commonly associated with such machines:

The most distinctive feature of a 2 Spindle Nut Tapping Machine is its two spindles or tapping heads. These spindles can work simultaneously on two different parts or locations, doubling the production rate compared to a single-spindle machine.

These machines often come equipped with variable speed and torque control, allowing operators to adjust the tapping speed and pressure to match the material being worked on. This feature helps prevent over-tapping or damage to the threads.

To streamline the tapping process, 2 Spindle Nut Tapping Machines often have automatic feed and retract mechanisms. This means that the spindles can advance to tap the hole, retract when the operation is complete, and move to the next workpiece without manual intervention.

Some advanced 2 Spindle Nut Tapping Machines may include a tool change system that enables quick and easy changing of tapping tools. This feature is especially valuable when different thread sizes or types need to be produced.

Many modern 2 Spindle Nut Tapping Machines feature a user-friendly touchscreen control panel. This interface allows operators to set parameters, monitor the machine's status, and make adjustments easily. Some machines may even offer programmable presets for different jobs.

These features make 2 Spindle Nut Tapping Machines efficient, versatile, and suitable for high-volume production where precision and speed are essential. They are commonly used in industries such as automotive manufacturing, aerospace, electronics, and general machining, where threaded holes are a common requirement.

If you want to know more about nut tapping machine price, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Straight Line Wire Drawing Machine LZ9/1200+Spool Take-up Machine GS 1250 | The Straight Line Wire Drawing MachineLZ9/1200+Spool Take-up Machine GS 1250 is a comprehensive solution for wire drawing and winding operations. T... | |

| Rainbow Punches And Dies | Punches and diesare crucial tools in the metalworking industry for cutting, shaping, and forming metal materials. A punch applies force to a workpi... | |

| Combined Wire Drawing Machine LZ2/800+LT8-13/650 | The Combined Wire Drawing Machine LZ2/800+LT8-13/650 is a highly efficient and flexible machinery that integrates two wire drawing processes - LZ2/... | |

| Multi-station Nut Forging Machine Introduction | Multi-station Nut Forging MachineIntroduction The multi station cold forging machineis a special equipment for the production of nuts and other ... | |

| Fine Wire Drawing Machine | Fine Wire Drawing Machine The Fine Wire Drawing Machineis an advanced machinery designed for precise and efficient reduction of metal wires, resul... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |