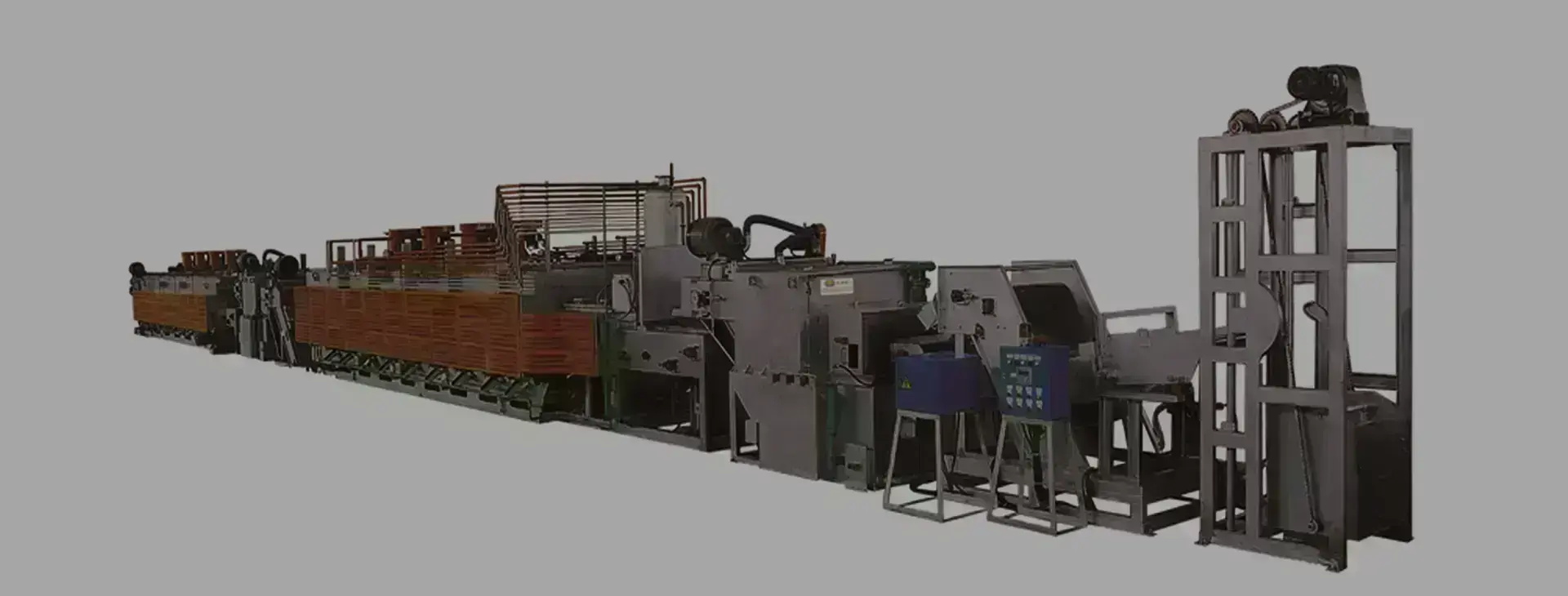

Spring Washer Making Machine

Spring Washer Making Machine

Spring Washer Making Machineis an advanced machinery designed specifically for the manufacturing of spring washers. With its precise control and automated processes, this equipment enables efficient and high-quality production of these essential fasteners used in various industries. It offers versatility in producing different sizes and specifications of spring washers, ensuring reliable and durable fastening solutions for a wide range of applications.

The Importance of Regular Maintenance for a Spring Washer Making Machine

Regular maintenance of a spring washer machineis crucial for several reasons. Firstly, it ensures the machine operates at its optimal efficiency. Regular checks and servicing can help identify and rectify any potential issues before they escalate into major problems, thus preventing costly repairs or replacements.

Secondly, regular maintenance enhances the machine’s lifespan. By keeping the machine clean, lubricating moving parts, and replacing worn-out components, you can significantly reduce wear and tear, thereby extending the machine’s operational life.

Thirdly, maintenance plays a vital role in ensuring the quality of the spring washers produced. A well-maintained machine is more likely to produce high-quality, consistent products, which is crucial in industries where the performance of the spring washers can directly impact the functionality of the final product.

Lastly, regular maintenance is key to ensuring the safety of the machine operators. A poorly maintained machine can pose significant safety risks, including mechanical failures or accidents. Therefore, regular checks and servicing are essential to provide a safe working environment.

In conclusion, regular maintenance of a Spring Washer Making Machine is not just an optional task, but a necessary practice that ensures efficiency, longevity, product quality, and safety.

Features of Spring Washer Making Machine

01

High Precision Manufacturing

The Spring Washer Making Machine offers precise control over the manufacturing process, ensuring consistent dimensions, thickness, and shape of spring washers for reliable performance and compatibility with mating parts.

02

Versatile Production Capability

This machine is designed to handle a variety of materials, such as stainless steel, carbon steel, and brass, allowing for the production of spring washers with different material properties to suit various applications and environments.

03

Efficient Production

The Spring Washer Making Machine operates with high efficiency, enabling rapid production rates and reducing lead times. It automates key processes, such as cutting, forming, and finishing, to streamline production and minimize manual labor requirements.

04

Easy Operation and Adjustment

This equipment is user-friendly with intuitive controls and easy setup. It allows for quick adjustment of parameters to accommodate different spring washer sizes and specifications, ensuring flexibility in production and adaptability to changing customer requirements.

Now the spring washer making machine priceis affordable, anything you need, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

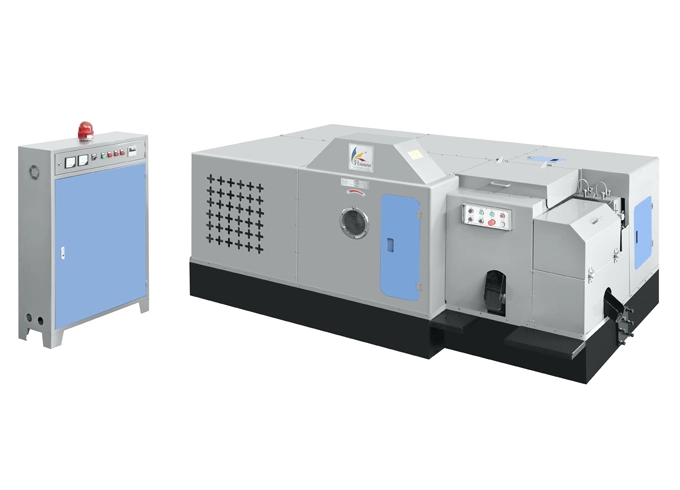

| Mesh Belt Furnace | The Mesh Belt Furnaceis a specialized industrial furnace used for heat treatment processes. It features a continuous mesh belt conveyor system that... | |

| Rainbow Heat Treatment Equipment | Heat Treatment Equipmentis a specialized tool used in industries like automotive, aerospace, and manufacturing to alter metal components' physical ... | |

| RNF Series 6 Station Nut Former | RNF Series 6 Station Nut Former Nut former machineis a special cold forging equipment for producing hex nuts. It adopts the cold forging method to... | |

| Screw Washer Assembly Machine | Screw Washer Assembly Machine The Screw Washer Assembly Machineis a cutting-edge automation solution designed to streamline the process of screw a... | |

| Combined Wire Drawing Machine LZ2/800+LT8-13/650 | The Combined Wire Drawing Machine LZ2/800+LT8-13/650 is a highly efficient and flexible machinery that integrates two wire drawing processes - LZ2/... |

Похожие товары

| XD-MAX Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | Продавец: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |