CNC Machining Brass

Brass is an object made of an alloy of copper and zinc. The melting point of brass with a copper content of 56%~68% is 934~967 degrees. Brass has excellent mechanical properties and abrasion resistance. So brass is a good material for manufacturing custom brass cnc machining parts. Brass machining parts, brass turning parts are widely manufactured for precision instruments, boat parts, gun cartridges, auto parts, medical accessories, and electrical accessories and so on.

Advantages Of Custom Machining Brass Parts

1. Brass cnc machining service have good strength, good plasticity, can withstand cold and hot pressure processing. Used for condensation and heat dissipation pipes, siphon pipes, serpentine pipes, and cooling equipment parts.

2. CNC Machining brass parts have extremely good plasticity and high strength, good cutting performance, easy to weld, very stable to general corrosion, but easy to crack.

3. Machined brass parts have good mechanical properties, good plasticity in hot state, and good plasticity in cold state

4. CNC milling brass parts have high strength, toughness, good anti-friction properties, and high corrosion resistance in the atmosphere and sea water. Used to make structural parts that work under friction and seawater corrosion conditions.

What are Common Types of CNC Machining Brass? And What are Their Properties and Application Fields

Brass is common in plumbing fittings, home decor, and musical instruments, mainly because of its soft material and easy workability. Brass' high polish is often found in cosmetic applications and is a good material for home decoration. It also does not spark when struck with another metal, making it ideal for use in potentially explosive environments. Lead was previously added to free-cutting brass to aid in machining. With the improvement of machinability, lead is now rarely contained. Corrosion-resistant brass is usually more difficult to machine than free-cutting brass, but it can be highly polished and is also resistant to seawater corrosion.

Below are some common machined brass material's properties and applications:

H96: H96 brass is composed of 96% copper and 4% zinc alloy

Properties: It has good cold and hot processing performance, suitable for extrusion, pressing, stamping, drawing, forging and other processing methods, easy to weld and tin-plated; it has high corrosion resistance in the atmosphere and light, and has no tendency to stress corrosion cracking.

Application field; H96 brass is generally used in currency; souvenirs; stamps;

H90: H90 brass is composed of 90% copper and 10% zinc alloy

Properties: H90 brass has good mechanical properties and hot and cold pressure processing performance, basically the same as H96. H90 brass is also suitable for upsetting, rolling engraving and hot forging, etc. It has good corrosion resistance and can be gold-plated and enamel-coated.

Application filed: H90 brass is generally used for cnc machining and lathing decorations products, medals, marine parts, rivets, waveguides, water tank straps, battery covers, water pipes, bimetallic products, etc.

H85: H85 brass is composed of 85% copper and 15% zinc alloy

Properties: It has good mechanical properties and corrosion resistance, excellent cold working performance and good thermoformability.

Application filed: H85 copper is widely used manufacturing architectural decoration, micro seals, corrugated pipes, serpentine pipes, water pipes, condenser and heat exchanger pipes, cooling equipment parts and other industries.

H70: H70 brass is composed of 70% copper and 30% zinc

Properties: It has relatively low plasticity and low strength, good cold formability, easy welding, good corrosion resistance, and is very sensitive to stress corrosion cracking in ammonia atmosphere.

Application field: H70 brass is widely used cnc machining sign labels, embossing, battery caps, musical instruments, flexible hoses, pump tubes, bellows, house construction supplies, etc.

H68: H68 brass is composed of 68% copper and 32% zinc

Properties: It has good plasticity and relatively low strength, good machinability, easy welding, corrosion resistance, and good cold and hot processing performance.

Application Field: H68 brass is widely used in manufacturing a range of cold stamping parts, radiator shells, bellows, guide tubes, doors, lamps, etc.

H65: H65 brass is composed of 65% copper and 35% zinc

Properties: It has sufficient mechanical properties and process properties, good cold and hot pressure processing performance, and golden color.

Application field: It is widely used in machining various hardware products, lighting, pipe fittings, zippers, plaques, rivets, springs, settlement over

Filters etc.

There are many brass cnc machining factories, but we are one of the best choices for you.

If you need any kinds of machining precision, please contact us, as a professional precision machining manufacturer, YS is willing to offer you high quality products.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| High Quality CNC Machining Service | Custom CNC Machining Service of Precision CNC Machined parts, CNC Turned Parts, from Metal to Plastic, 1 Piece Prototype to Mass Production Lookin... | |

| CNC 5-axis Machining | If you want to find a cost effective china 5 axis machining services for your product, YS Rapid can be a good choice for you. Based on our rich exp... | |

| Precision Machining Aluminum Components | The properties of aluminum, such as corrosion resistance and light weight, play an important role in the production of electronic product parts and... | |

| Precision CNC Milling 6061-T6 Aluminum Machined Parts | Are you looking for a high-quality custom precision aluminum machining supplier? YS rapid is a CNC milling components factory with many years of ex... | |

| CNC Turning | CNC Turning CNC Turning is also called cnc lathing. The high quality ChinaCNC turningis a manufacturing process in which bars of workpiece are hel... |

Похожие товары

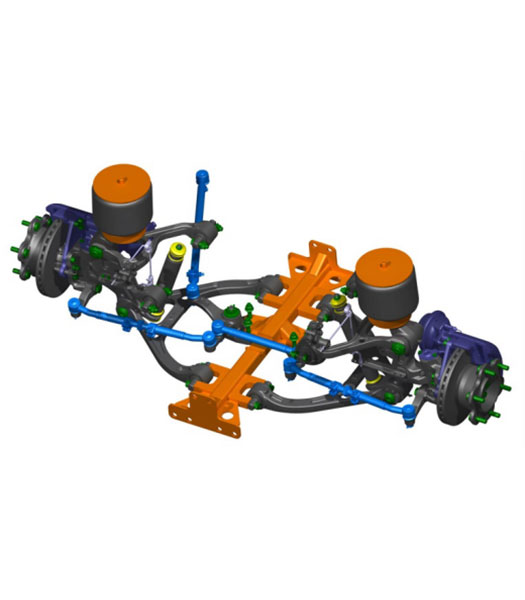

| Independent Air Suspension | Продавец: Shanghai Komman vehicle component systems stock co., ltd | Air suspension systemis generally divided into independent air suspension and nomal air suspensio... | |

| D11 Motor Mount For Bosch Ebike Motor | Продавец: Shanghai Komman vehicle component systems stock co., ltd | Port: Shanghai, China Production Capacity: 20000T/Year Paymen... | |

| Bus Air Suspension | Продавец: Shanghai Komman vehicle component systems stock co., ltd | What is air suspension bus Bus air ride suspensionis also called air bag suspension,the differen... | |

| 6-8m Bus Front Air Suspension System | Продавец: Shanghai Komman vehicle component systems stock co., ltd | 6-8m Bus Front Air SuspensionSystem Port: Shanghai, China Production Cap... | |

| 50 Cylinder Diameter Shock Absorber | Продавец: Shanghai Komman vehicle component systems stock co., ltd | Item name: Shock absorber Port: Shanghai, China Production Ca... |