Keller OEM Sensors, Transducers Series 10 10PD OEM all media pressure sensor PAA-23SY EI PA-21Y15bar 81554.55 PA-21SC 30bar 80440.11

The Series 10 pressure transducers cover all pressure ranges from 100 mbar to 1000 bar. PR-10

PD-10 PAA-10 PA-10

The KELLER Series 10 sensor is mounted with the compensation resistors in a stainless steel housing. The sensor floats on an O-ring seal and is therefore free of any housing stresses. It is particularly suited in connection with PAP-based signal processing. Transducers can be ordered with the coefficients of a mathematical model ready for integration with a PAP-base

system. Error Bands of 0,1%°≠0,01 %FS are achievable, depending on the temperature ranges Whilst the Series 11 fulfils all the classical functions expected of a mV-transducer, it is often used in development of larger OEM projects to test the performance of the KELLER OEM sensors. As a special order, any OEM sensor from Series 3 to 10 can be ordered in such a housing, with or without integrated compensation resistors. The customer can then verify that the chosen OEM sensor is suitable for the application.

SPECIFICATIONS (Excitation I = 1 mA)

Ranges (FS)

Version PAA, PA, PR-110,10,20,51251020bar

Overpressure2,52,52,52,5371530bar

Output Signal nominalmV

Version PAbar

Overpressurebar

Output Signal nominalmV

PR-11(negative range) -0,1-0,2-0,5-1bar

SERIES PA 13 LOW PRESSURE

Pressure Rangesbar

Overpressurebar

Signal Output typ.mV

ERIES PA 13 HIGH PRESSURES

Pressure Ranges4006001000bar

Overpressure5007001100bar

Signal Output typ.

PA: Sealed Gauge. Zero at atmospheric pressure (at calibration day)

Linearity, incl. Hysteresis< 0,5% FS (0,1 /0,2% FS at reduced Full Scale)

Repeatability< 0,1% FS

Keller OEM Sensors, Transducers Series 15 - 15M Piezoresistive pressure transducers flush diaphragm

The TAB 1 pressure measuring cells are designed to measure absolute pressures. They are

offered in two different version: Version 1 to be soldered on a glass feed through and welded

in an oil filled housing as for industrial transmitters. Version 2 can be soldered directly on

printed circuit boards of instruments as for the measurement of depths or altitude, where the

surrounding pressure is measured.

Speciications

General Characteristics: Excitation I = 1 mA constant current

Ranges (FS) bar -0,1 -0,2 -0,5 -1 0,1 0,2 0,5 1 2 5 10 20

PR PR-PAA-PD PR-PAA-PA-PD PR-2/1 bar/8750.8

PR-PAA-PA PR-PD

PAA: Absolute, Zero at vacuum PA: Absolute, Zero at ambient (sealed gauge) PR: Gauge PD: Differential

Ranges, Overpressure, Output Signal (FS)

Series 3L...10L, a new range of transducers that beneit from smaller capsule dimensions and crevice free diaphragms. KELLER has developed a new technique for laser welding very thin stainless steel media isolation diaphragms. The smaller crevice free transducers still retain all the traditional performance, stability, and quality, for which KELLER is renowned.

Keller OEM Sensors, Transducers Series 6S / SC OEM all media pressure sensor

SPECIFICATIONS Excitation I=4 mA PR-6 ! *0,3*0,5*1,02,05,0 1020 * also neg. ranges possible bar 0,30,51,02,05,0 1020bar

PAA-6 ! 1,02,05,0

PA-6 !

400600 bar

PR: Vented gauge pressure PAA: Absolute pressure PA: Sealed gauge, zero at 1 bar absolute

Keller OEM Sensors, Transducers Series 7S / 9S OEM all media pressure sensor

Pressure Ranges (FS) and Overpressure in Bar. Signal Output in mV.

PR-7 S / 9 S (7 S: only from 5 bar) -1 -0,5 -0,2 -0,1 0,1 0,2 0,5 1 2 5 10 20

PAA-7 S / 9 S (7 S: only from 5 bar) 0,1 0,2 0,5 1 2 5 10 20

PA/PAA/PR 9 FL (thin lange) 0,1 0,2 0,5 1 2 5 10 20

PA-7 S / 9 S (7 S: only from 5 bar) 1 2 5 10 20

PA-9 FL (thick lange) 50 100 200

Signal Output typ. * (mV) 75 50 25 15 15 30 60 100 140 200 225 225 225 225 225

Overpressure (bar) -1 -1 -1 -1 2,5 2,5 2,5 3 4 7 15 30 100 200 300

The Series 8 pressure sensors are extremely durable, even when exposed to fast pressure peaks. They have been developed especially for the measurement of high pressures. The Series 8 sensor for ranges 400!-1000 bar uses thicker glass feed through and a wire-bonded measuring cell.

Pressure Ranges (FS) and Overpressure in Bar. Signal Output in mV.

PAA-8 10 20

PA-8 10 20 50 100 200 400 600 1000

Signal Output typ.* 225 225 225 225 225 225 225 225

Overpressure 20 40 100 200 300 600 900 1100

Whether embedded in an OEM product or simply packaged as a high-end pressure transmitter, the Series 30X enables the OEM to offer superior performance without the need for huge R&D or capital expenditures, and with minimum amount of on

hand inventory. Designed to be easily integrated into a wide variety of applications, the 30X features a flush-welded dia-

phragm and highly stable piezoresistive sensing element.

The Series 4 LC to 9 LC is characterized by having fully integrated compensation and signal standardization over the entire temperature range from -40 to 150 Technology KELLER grew up in the 1970s with OEM pressure transducers.

The Series 4 LD...9 LD is based on KELLER’s famous Chip-In-Oil (CIO) technology. The “L”stands for the laser welded stainless steel housing and could equally be representative for lowpower (typ. 0,1 µA in idle/sleep mode) and low-voltage (Supply: 1,8...3,6 VDC). The housing is hermetically-sealed, oil-filled and builds a Faraday cage with feed-through capacitors around the entire electronics. The digital interface of the electronics with dual information of pressure and temperature is indicated by the “D”.

The “…LY” transmitter line benefits from smaller sensor dimensions, crevice-free diaphragms and low Total Error Band performance.The innovative signal conditioning circuit ‘learns’ thermally-induced zero and span errors during calibration. Series 9LY, 9FLY, and 10 LY Series 7LY

Whether embedded in an OEM product or simply packaged as a high-end pressure transmitter, the Series 9LX enables the OEM to offer superior performance without the need for huge R&D or capital expenditures, and with minimum amount of on hand inventory

SPECIFICATIONS

Available ranges

Relative 1, 3, 10, and 30 bar

Absolute 1, 3, 10, and 30 bar

Proof Pressure 2X basic range

Accuracy, TEB Analog: !à0.15% FS TE

Digital: !à0.1% FS TE

Operating Temperature Range -40...100!a

Compensated Temp. Range -10...80!a

Output 4...20mA + RS485

0...10VDC + RS485

Resolution 0.002% BR

Analog Update Rate 400z

Supply

Voltage Output 13...28 VDC

Current Output 8...28 VDC

RS485 Only 8...28 VDC

Load Resistance

Current <(Supply-8V)/0.02A

Voltage >4k ohm

Electrical Connectivity Solder pads or Molex Milli-grid

(2mm)

Bus Compatibility Modified-MODBUS protocol, up to

128 devices

Construction Materials Std. 316L Stainless Steel

Opt. titanium or Hastelloy C-276

Viton O-ring: 15.6mm ID x

67.Keller Swiss-Built Series 22DT Dual fuel pressure-temperature transmitter

Series 22 offers a reliable cost effective solution for customers requiring medium to high quantities, of mass produced transmitters. Utilising the KELLER automatic brazing lines, this new technology allows crevice-free construction of the pressure port with no internal seals or O-rings, making possible high volumes at low cost. In the brass 22 M, a steel insert and a nickel diaphragm are brazed into a brass housing. In the steel 22 S, all parts are stainless steel (AISI 316 L). The glass

feed-through header and silicon pressure sensor are welded to the steel insert underneath the oil illing.

The electronic circuit is itted to the Packard plug. EMC-protection-components are mounted on the plug side, the ampliier on the sensor side. A lexible printed circuit !°TAB!± connects the senso. Series 22 M 3/8!±-24 UNF-2 with the electronics. The transmitters are designed to have exceptionally good EMC ratings and operate over a wide temperature band, ideal for automotive, hydraulic and refrigeration control applications.

Speciications Pressure Ranges

PAA-22 M / PAA-22 S 5 10 20 30 bar

PA-22 M / PA-22 S 5 10 20 30 50 100 200 250 bar

Overpressure 15 30 60 90 150 250 300 300 bar

The Series 41 X combines the ceramic measurement cell for low pressure ranges with the µP electronics of the digital Series 30 transmitter. The pressure values from the signals of the pressure and temperature sensors are determined by polynomial compensation (see reverse). The values can be displayed and stored on a PC via an RS485 interface and programming can also be carried out. The transmitters are calibrated to the base range. The PROG30 software permits programming of the analog output signal in each section of the range within the base range (e.g. range 100 mbar. Output 4…20 mA for 20…60 mbar). With KELLER RS converters K-100 Series, up to 128 transmitters can be hooked together into a bus system and read by means of a PC or laptop. READ30 software allows the current pressure of each transmitter to be read or the pressure activity of several transmitters to be recorded or stored whilst “on line”.

Specifications

Standard FS Pressure Ranges

PR-41 X (relative) PD-41 X (diff.) 30 100 300 mbar

Overpressure 300 1000 1500 mbar TheSeriesPRD-33Xwasdevelopedforapplicationsthatrequireahighaccuracydifferentialpressuremeasurementtogetherwithhighoverloadresistanceindifferentialpressurerangesaslowas350mbar.TheSeriesPRD-33XistheresultofongoingdevelopmentoftheKELLERPD-33Xdifferentialpressuretransmitters.

The KELLER Series 21 / 21 PRO are extremely reliable and cost effective pressure transmitters. These pressure transmitters use a programmable KELLER-ASIC microchip called!±ProgRes!± (programmable resistors).

The modular design of the Series 21 C and the extensive vertical range of in-house manufacture provide a high degree of lexibility. The company can quickly adapt to customer requests, even with large production batches. The extensive standard range of connectors and pressureconnections means that a CIO measuring cell (Chip-in-Oil) can be quickly welded in from stock if small numbers are involved, and then calibrated to the required temperature range. RoHS conformity and comprehensive EMC protection are a matter of course, thereforequalifying the Series 21 C for use in industrial areas.

Specifications

Pressure ranges (all intermediate ranges possible)

PA-21 C / PAA-21 C 2!-100 bar max

Overpressure 2,5 x pressure range Piezoresistive Pressure transmitters for industrial aPPlications

series 21 G

• Weighing only 30 grams, the smallest known transmitter with fully welded stainless steel wetted parts

• High EMC protection. Protection class IP65/IP67

• Highest stability due to special heat treatment and annealing procedures

Series 21G, is the result of a 20 year long development programme for industrial transmitters. ‘G’ stands for ‘Graduate’; this product has received ‘summa cum laude’.... the highest honours. The standard mPm electrical connector overlaps the body to remind us of ‘mortar board hats’ on graduation day.

These piezoresistive silicon pressure transmitters are produced on the new KELLER automatic brazing lines, making possible the mass production of high quality pressure transmitters at low cost.This new technology allows the crevice-free construction of the pressure port without using seals or O-rings. In the brass sensor line (Series 21 MC), a steel insert and a nickel

diaphragm is brazed into a brass housing. In the steel sensor line (Series 21 SC), all parts are of stainless steel (AISI 316 L). The header with the silicon pressure sensor and glass lead through pins is welded to the steel insert underneath the oil filling. The tiny chip-on-board amplifier (weight 1 gram) with the KELLER-specific !°PROGRES!± circuit is mounted direct

on the glass feed-through pins. It is then encapsulated in silicone compound for humidity and vibration protection.

Note: The cable version of the transmitters has exceptionally high RFI protection.

SPECIFICATIONS

Pressure Ranges (FS) PA

Sealed Gauge (zero at 1 bar abs.) bar

Series 21 MC Overpressurebar

Brass Sensor Head, Steel Body 3-Wire 4-Wire

2-Wire Excitation8!-28 V4,75!-5,25 V5!-1

ERIES 21 SC SERIES 21 MC S

This new range of KELLER OEM pressure transmitters offers the user the high accuracy and stability of the KELLER piezoresistive pressure capsule in a low cost OEM package. Applications include refridgeration, hydraulic controls, air compressors, ink jet printers, vacuum pumps etc.

The Series 21 R is offered with soldered brass transducers (Series 21 MR), soldered steel transducers (Series 21 SR) or fully welded (Series 21 R), all providing a highly stable measuring cell with negligible hysteresis, unrivalled linearity, high output and a life of millions of pressure cycles.

Outputs: A 2-wire (4!-20 mA) or 3-wire version with voltage output is available as an output signal. For a ratiometric 0,5 to 4,5 V version, we refer to the KELLER Series 21 G product range. EMC: The 21 Y product line is outstanding due to its extreme ruggedness towards electromagnetic ields. The limits of the CE standard are undercut by a factor of up to 10 with conducted and radiated ields. These transmitters are also extremely immune to external voltages between the housing and the electrical connection, which is particularly important when frequency converters are being used. The high insulation voltage of 300 V make this product ideal for use in the harshest of environments.

Specifications

Pressure Ranges (all intermediate ranges possible)

PR-21 Y 2!-10 bar FS

PAA-21 Y / PA-21 Y 2!-100 bar FS

Overpressure 2 x pressure range, max. 1100 bar

PAA: Absolute. Zero at vacuum PA: Sealed Gauge. Zero at 1000 mbar abs. PR: Vented Gauge. Zero at atmospheric pressure

Accuracy

Series 22 DT was developed and homologated specially for use in so-called °∞bivalent vehicles fitted with engines for combined natural gas/gasoline operation. The unconventional design with a small mass swept by the flow results in a fast response with temperature changes, the temperature being measured by an NTC or PT sensor located directly behind

the stainless steel separating diaphragm. The same diaphragm transmits pressure via a capillary to a stress-free mounted silicon measuring cell. The signal processing for pressure and temperature is carried out by an electronic module connected to the sensors by flexible conductors. Mounted to the back of the electronic module, which is directly connected to the 6-pole plug connector are the EMC protection components. A special feature is the immunity from interference from electromagnetic fields up to 200 V/m.SPECIFICATIONS

Pressure Range PA-22 DT14 bar Sealed Gauge. Zero at atmospheric pressure (at calibration day)

Series 22 offers a reliable cost effective solution for customers requiring medium to high quantities,

of mass produced transmitters. Utilising the KELLER automatic brazing lines, this new technology

allows crevice-free construction of the pressure port with no internal seals or O-rings, making

possible high volumes at low cost. In the brass 22 M, a steel insert and a nickel diaphragm are

brazed into a brass housing. In the steel 22 S, all parts are stainless steel (AISI 316 L). The glass

feed-through header and silicon pressure sensor are welded to the steel insert underneath the

oil illing.

The electronic circuit is itted to the Packard plug. EMC-protection-components are mounted on

the plug side, the ampliier on the sensor side. A lexible printed circuit !°TAB!± connects the senso

Series 22 M

3/8!±-24 UNF-2

with the electronics. The transmitters are designed to have exceptionally good EMC ratings and

operate over a wide temperature band, ideal for automotive, hydraulic and refrigeration control

applications.

Speciications Pressure Ranges

PAA-22 M / PAA-22 S 5 10 20 30 bar

PA-22 M / PA-22 S 5 10 20 30 50 100 200 250 bar

Overpressure 15 30 60 90 150 250 300 300 bar

The Y-line transmitters have an extremely small temperature error. This is achieved using an additional circuit containing a temperature sensor that subdivides the temperature range into fields that are 1,5 Kelvin (K) wide. The TK zero and TK compensation values are calculated for each field and programmed into the additional circuit. During operation, these values are fed into the analogue signal path depending on the temperature. Each temperature is the „calibration temperature” for this transmitter. The accuracy thereof is mainly determined by linearity. 120 fields are available, representing a possible temperature range of 180 K. The wider the temperature range, the greater the amount of testing that is needed to minimise the inaccuracy of the mathematical model. The Series 23 (S)Y/25 Y product line is outstanding due to its extreme ruggedness towards electromagnetic fields. The limits of the CE standard are undercut by a factor of up to 10 with conducted and radiated fields.

· Series 23 Y Ranges 0,2…2 bar Floating mounted sensor. Internal O-Ring.

· Series 23 SY Ranges 1…1000 bar Fully welded (no internal seals)

· Series 25 Y Ranges 0,5…100 bar Flush, fully welded.

These piezoresistive transmitters have been designed for precision applications in industrial environments for pressures ranging from 0,2 to 1000 bar, liquids or gas.

Series 23: Male pressure port

Series 25: Flush diaphragm

A Complete Range Absolute, barometric, gauge (over- and underpressure) and differential for wet/wet applications.

13 nominal pressure ranges. Current or voltage output. Flexibility A modular concept uses the selection of off-the-shelf capsules, allowing a customised production. Numerous options and variants are available, fully adapted to the customer’s requirements: Mechanical and electrical interface, ports, signal outputs, materials in media contact, oil filling, oxygen-compatibility, special features, flameproof versions…Reliability / QualityThese transmitters use the highly stable KELLER Series 10 capsules, proven in millions of applications throughout the world. Each capsule is subjected to severe tests and calibration procedures. The transmitters are manufactured and tested according to ISO 9001 / EN 29001.The type of the transmitter is defined according to the reference pressure:

PAA-23/25 Absolute Pressure Transmitter (Zero at 0 bar abs.)

PA-23/25 Sealed Gauge Pressure Transmitter (Zero at ≈ 1 bar abs.)

PR-23/25 Vented Gauge Pressure Transmitter (Zero at atmospheric)

PD-23 Differential Pressure Transmitter (wet / wet)

In addition to the classical analog output signal (Series 23 Ed and 25 Ed), a digital solution based on the successful high-precision Series 30 X transmitters is also

available (33 X Ed and 35 X Ed). nalog transmitters, Series 23 Ed and 25 EdThis series is based on the stable piezoresistive transducer with analog electronics.

Specification Standard Pressure Ranges (FS) and Overpressure in bar

PR-23/25 Ed, PR-33/35 X Ed -1 1 3 10 30

PA(A)-23 Ed, PA(A)-33 X Ed 1 3 10 30 100 200 300

PA-25 Ed, PA-35 X Ed 1 3 10 30 100

68. Keller Swiss-Built Series 23S-25S High accuracy compact pressure transmitter

The Series 23S / 25S features a fully welded pressure port construction, nointernal O-Rings or seals are used up to 600 bar. Pressure ranges, pressure ports, signal outputs, electrical connectors, etc.Quality Each transmitter is subjected to severe test- and calibration procedures. Transmitters are manufactured and tested according to ISO 9001:2000.

Specifications

Pressure Ranges (FS) in Bar

PR-23 S / PR-25 S G1/2! -1 -0,5 -0,2 0,2 0,5 1 2 5 10 20

PAA-23 S / PAA-25 S G1/2! 0,5 1 2 5 10 20

PA-23 S 1 2 5 10 20 50 100 200 400 600 1000

PA-25 S / PA-25 TAB G1/2! 1 2 5 10 20 50 100 200 400

This piezoresistive pressure transmitter fits 19 mm (3/4”) manifold pressure ports for applications in bio-reactors or autoclaves. The transmitter is compensated up to 150 °C and may be operated continuously or sterilised at this level, including the special circuit electronics. The transmitter circuit is based on the “PROGRES” programmable KELLER amplifier.

This piezoresistive high temperature transmitter (-transducer) is suited for media temperatures up to 300!aC. The pressure, acting onto the flush diaphragm, is transferred over an oil-fille capillary onto the silicon measuring cell. The capillary has the function of a cooling spiral. When measuring media with temperatures of 300!aC, the temperature at the silicon cell onl

increases by 100!aC. The integrated amplifier electronics provide a voltage- or current signa proportional to the pressure.

For highly aggressive media, KELLER offers pressure ports in different materials.

SPECIFICATIONS

PA(A) 25HTC PAA: Zero at Vacuum PA: Zero at 1bar absolute

PR-25HTC PR: Vented Gauge

This high precision of 0,01 %FS is available as an option (the standard Series 33 X has an accuracy of 0,05 %FS). These Series are based on the stable, floating piezoresisitive transducer and the newly developed XEMICS micro-processor with integrated 16 bit A/D converter. Temperature dependencies and non-linearities of the sensor are mathematically compensated.

Specifications

Standard Pressure Ranges (FS) and Overpressure in bar

PR 33 X / PD 33 X / PR 35 X 1 3 10 30

PA(A) 33 X / PA(A) 35 X 0,8…1,2 1 3 10 30 100 300 700 1000

Overpressure 2 2 5 20 60 200 400 1000 1000

Overpr. referential pressure side PD 2 5 7 20

PD, static line pressure*

standard / high Pressure 200 bar / 600 bar

Standard Pressure Ranges (FS) and Overpressure in Bar

PR-33 X Ei, PR-35 X Ei,

PR/PA(A)-36 XW Ei 1 3 10 30

PA(A)-33 X Ei, PA(A)-35 X Ei 0,8…1,2 3 10 30 100 300 700 1000

Swiss-Built Series 35X HT-HTT High temperature high accuracy analog digital output pressure transmitter Piezoresistive pressure transmitter for applications in bio-reactors or autoclaves. The transmitter is compensated up to 150 °C and may be operated continuously or sterilised at this level, including the special circuit electronics. The transmitters are supplied in absolute or gauge versions, with current or voltage output. The sensing component is a micro-machined silicon pressure chip of high sensitivity. An independent temperature sensor is integrated on the surface of the silicon chip.

STANDARD PRESSURE RANGES (FS) AND OVERPRESSURE IN BAR

PR 35 X HTC 3 10 30

PAA 35 X HTC 3 10 30 100 300 1000

In applications where the differential pressure is more than 5% of the maximum standard pressure range, differential pressure measurement with two absolute pressure sensors offers major advantages over conventional methods of differential pressure measurement (such as the Series PD-10). The Series PD-39 X does not measure the differential pressure directly - instead, it uses two absolute pressure sensors to take the measurement indirectly. As well as reducing costs, this differential pressure transmitter is also more robust in relation to unbalanced (one-sided) overloading. The differential pressure range should be at least 5% of the standard pressure range.

The Econoline by Keller America is a general purpose pressure transmitter intended for almost any application involving aggressive media and where small size, weight, and low cost are required. This proven design utilizes a media isolated, piezoresistive silicon sensor, a design known to be highly reliable in thousands of applications around the globe. Combined with state-of-the-art signal conditioning electronics, the result is a robust transmitter that will provide trouble free service and

accurate results. For more information on the Econoline, or any other Keller product, please con-tact Keller America, or view the entire.

The Preciseline by Keller America pro-vides standard features that far exceed those of comparably priced transmit-

ters by combining proven piezoresistive silicon sensor technology with Keller!ˉs state-of-the-art signal conditioning cir-

cuitry. The result is outstanding !à0.25% FS standard (!à0.1% optional) Total Error Band (TEB) accuracy over a wide com-

pensated temperature range. The ability of the Preciseline to provide this level of sustained performance over a wide range of operating condi-tions makes it ideally suited to pressure monitoring applications such as tank level measurement, pump control, and VFD control. Plus, guaranteed lightning protection makes this transmitter ideal for installation in areas prone to chronic damage due to transients caused by lightning.

Series 23 (S) Ei, 25 (S) Ei and 26 Ei pressure transmitters are all ATEX approved for use in Hazardous Areas where there is a high risk of explosion. Series 23 Ei / 26 Ei The Series 23 Ei / 26 Ei achieve high stability (especially in low pressure ranges) with large piezoresistive capsules and stress-free, floating mountings with O-rings. Series 23 S Ei / 25 Ei / 25 S Ei

The 23 S Ei / 25 Ei / 25 S Ei offer a complete range of „Ported“ and „Flush Diaphragm“ pressure transmitters for ranges of 1bar and above. Still giving high stability and accuracy but without any internal O-rings. This is achieved using either an all welded 316L stainless steel housing and diaphragm or an all welded 316L housing fitted with a brazed Nickel diaphragm.

– A complete range Absolute, barometric, gauge (positive and negative). 16 nominal pressure ranges. Current or voltage output.

– Flexibility A modular concept is used, with fast and economical production achieved by using off-theshelf sensors. Numerous options and variations are available to meet customers’ specific requirements: Pressure ranges, mechanical- and electrical interface, process- and plug connection, signal outputs etc.

– Reliability / Quality

Each transmitter is subjected to severe test- and calibration procedures. Transmitters are manufactured and tested according to ISO 9001.

Specifications

Pressure Ranges (FS) in Bar

PR/PAA-23 Ei, PR/PAA-25 Ei / 26 Ei -1 -0,5 -0,3 0,3 0,5 1 2 5 10 20

PR/PAA-23 S Ei, PR/PAA-25 S Ei 2 5 10 20

PA-23 Ei, PA-25 Ei 1 2 5 10 20 50 100 200 400 600 1000

PA-23 S Ei 2 5 10 20 50 100 200

PA-25 S Ei 2 5 10 20

Другие товары поставщика

Все товары поставщика

Похожие товары

|

|

Low-E Braided Packing, Flexible Graphite, Fiberglass, Custom |

Продавец: China LiCB AC DC EV Charger Co., Ltd |

The Low Emission Braided Packing Manufacturer delivers high-performance flexible graphite valve p... |

|

|

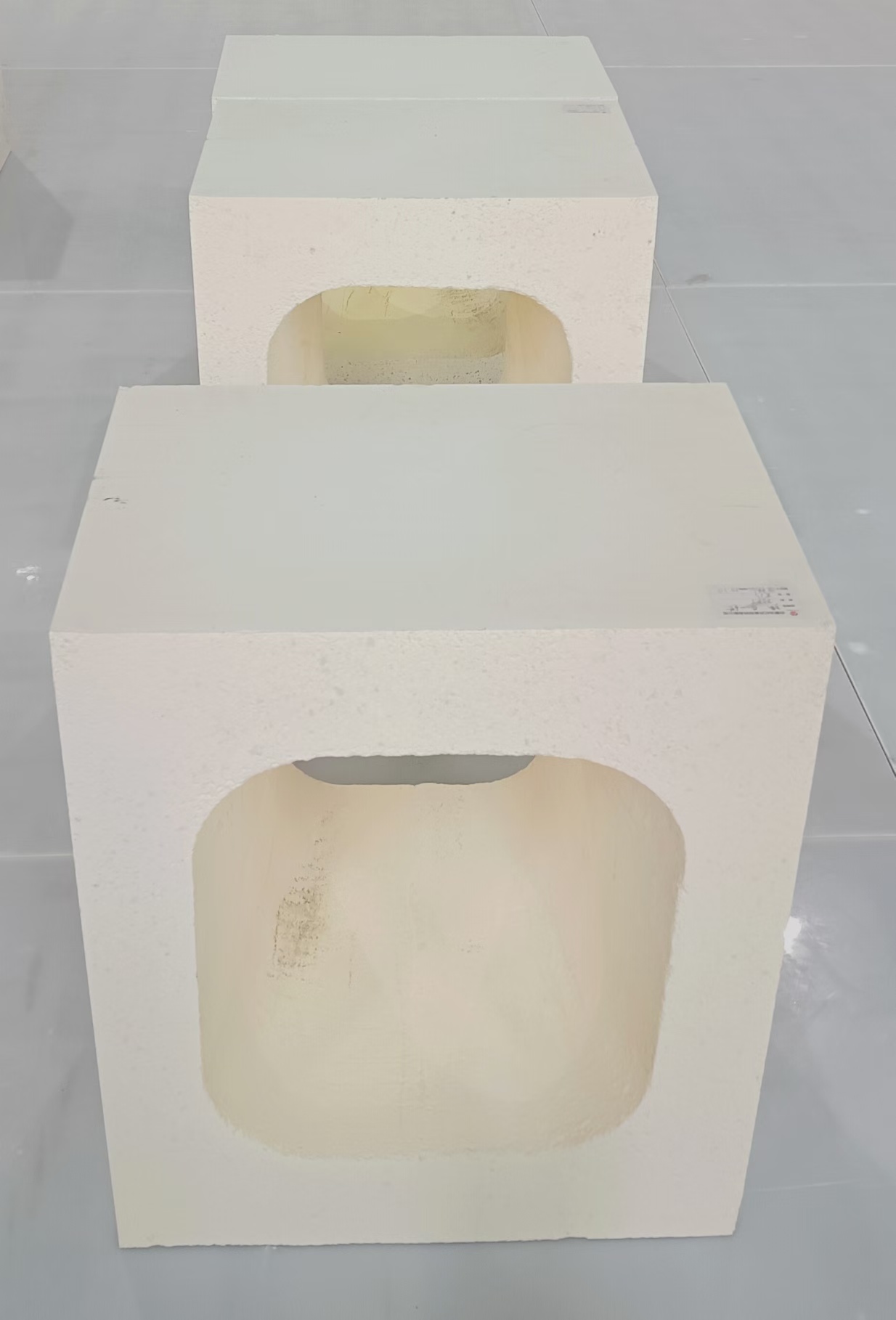

fused AZS block |

Продавец: Sino-Inner Mongolia Easun Refractory Co.,Ltd |

Weir block

AZS-33 серия продуктов обладает высокой устойчивостью к атаке стеклом, низкой склонно... |

|

|

fused AZS block |

Продавец: Sino-Inner Mongolia Easun Refractory Co.,Ltd |

Channel block

AZS-33 серия продуктов обладает высокой устойчивостью к атаке стеклом, низкой скло... |

|

|

fused AZS block |

Продавец: Sino-Inner Mongolia Easun Refractory Co.,Ltd |

Peep hole block

AZS-33 серия продуктов обладает высокой устойчивостью к атаке стеклом, низкой ск... |

|

|

fused AZS block |

Продавец: Sino-Inner Mongolia Easun Refractory Co.,Ltd |

АЗС-33 AZS-33 серия продуктов обладает высокой устойчивостью к атаке стеклом, низкой склонностью... |