Cassava Starch Machine 2019

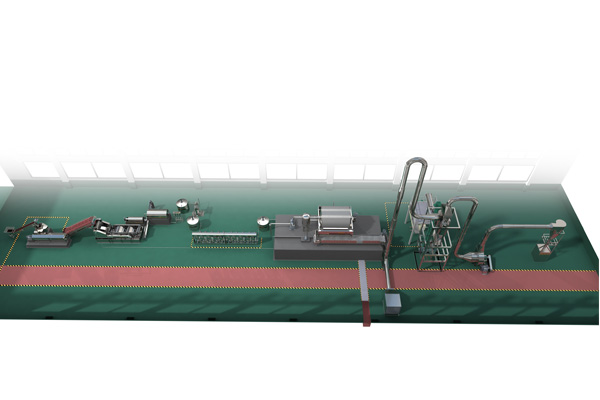

Cassava (tapioca) Starch Process Description and Flowchart:

Goodway has been continuously developing cassava tapiocastarch processingmachine since 1991 to maximize product quality. From cassava root hopper until the packaging stage, we can supply machines (tapioca processing machine) together with production process know-how.

The cassava starch production process(tapioca) comprises the steps such as delivery and unloading cassava, washing, peeling, crushing, slurry and residues separation, desanding & desilting, starch concentrating and refining, de-watering, starch drying, and packaging.

We provide below a brief description of the main steps of the cassava starch(tapioca) production process. The cassava starch machine is also known as the tapioca starch machine.

Note: Goodway updates the cassava starch processing equipment and cassava starch processing production line technology and machinery based on the latest experience.

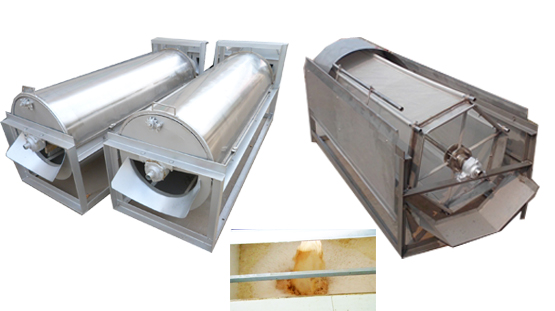

Cleaning and Washing Cassava (tapioca) Roots

Wash the fresh cassava (tapioca) roots in clean water to remove the surface mud and sand. It's the first step of cassava starch process and very important for the quality of final cassava starch(tapioca).

Peeling Cassava (tapioca) Roots

Peel the washed cassava (tapioca) roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

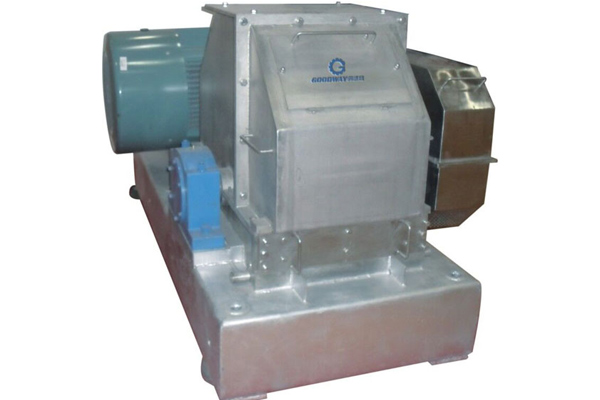

Crushing Peeled Cassava (tapioca) Roots into Slurry

Crushing the peeled cassava (tapioca) roots into the slurry and separate to remove the coarse cassava residues to obtain uniformly smooth cassava slurry. The crushing drum and all food contact areas should be made from stainless steel.

Cassava (tapioca) Slurry and Residues Separation

The commonly physical operation to separate fine cassava residues from cassava slurry. Oversize particles of cassava residues cannot pass through the lattice structure of the filter, while fluid and small particles of cassava slurry can pass through to become filtrate.

Raw Starch Milk Desanding and Desilting

Solid control equipment that separates tiny sand and mud from the raw starch milk. Desander is installed before the desilter and normally the solids diameter for desander to be separated would be larger than for desilter.

Starch Refining and Concentrating

When raw starch milk enters the hydrocyclone, the pure starch milk of high density getting larger centrifugal force leaves from the underflow outlet, and the protein and other soluble impurities of low density getting smaller centrifugal force leave from the overflow outlet. Finally, achieve the purpose of various components of separation, and improve the quality of final starch with higher whiteness and purity.

Pure Starch Milk De-watering

De-watering the pure starch milk to low water content of 35-40% by the principle of vacuum suction filtration. Ensure sufficient water has been removed, otherwise, the starch will form into lumps during drying.

Drying Wet Starch into Dried Starch

Effectively dry the wet starch into dried starch(tapioca) with low moisture content by the principle of heat transfer exchange. The drying process is more reliable and of higher quality.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Potato Starch Processing Plant | Features of Potato Starch Processing Plant In the field of starch processing, each person's processing conditions are different, and the types of ... | |

| Cassava Rasper Machine | Features of Cassava Rasper Machine Cassava Crusher - Cassava Rasper Machine Processing Capacity: 15-35Tons/hour Application Scope: Crushing the ... | |

| Cassava Chips Cutting Machine | Features ofCassava Chips Cutting Machine Cassava Chips Process Description and Flowchart: Cassava chips are one kind of chips or slices made fro... | |

| Fufu Machine | Features of fufu processing machine Fufu processing machine for sale - Make Fufu(foofoo) from Fresh Cassava Fufu Process Description and Flowchar... | |

| Cassava Chips Cutting Machine | Cassava Chips Process Description and Flowchart: Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal f... |

Похожие товары

| 4-Shaft Winder Cast Film Machine | Продавец: Wenzhou Chaoshun Machinery Co., Ltd. | The 1500–2100mm PVC Cast Film Machine (4-Shaft Winder) is a robust solution built for indus... | |

| Standard Washer 12/15/20/25kg | Продавец: Jiangsu Chuandao Intelligent Equipment Co., Ltd. | Kingstar Series washer extractors equipped with the world’s leading washing technology, Ita... | |

| Daily Necessities Molds | Продавец: Zhuozhou Yihua Mould Factory | Daily Plastic Products are the most extensive category of plastic products. Most of the plastic p... | |

| Rebar Coupler Threading Machine | Продавец: Xingtai Yushi Machinery Equipment Co., Ltd | Rebar Coupler Threading Machineis an essential tool for processing reinforced bars, commonly used... | |

| VH HIGH-SPEED GANTRY PROCESSING | Продавец: Ling Yueyang International Trade (Shenzhen) Co., Ltd | ●Powerful cutting capability combined with high precision and performance makes insert and armori... |