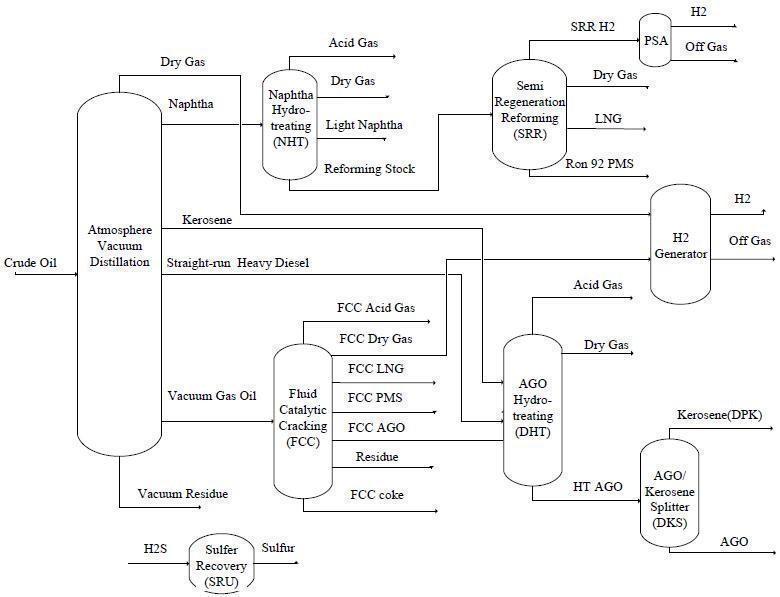

Diesel Hydrotreating Unit

OVERVIEW Hydrotreating process (DHT): uses hydrogen to desulfurization unit the naphtha fraction from the crude oil distillation or other units within the refinery. Application of DHT: 1. Remove impurities and polluted elements from diesel fraction with a high efficiency 2. PCC's DHT can increase the performance of diesel product 3. The production process of diesel can be more environmental friendly by using our unit. Advantages of DHT: 1. The energy consumption of PCC's DHT product is very low 2. The price of PCC's DHT product is economical PCC prides itself as a leading refinery factory, We provide hydrogen desulfurization Unit, solvent recovery plant design, oil refinery engineering, etc. Want to know the details of gas oil hydrotreating process or dht oil? please contact us.

Другие товары поставщика

|

|

Hydroskimming Refinery |

Catalog of Hydroskimming Oil Refinery Mode Capacity (BPD) Power (Kw/d) Fabrication Period (month) Area (Acre) Skid Number Weight (Ton) MR150 15000 ... |

|

|

Vacuum Distillation Unit |

Vacuum Distillation Unit (VDU): further distills the residue oil from the bottom of the crude oil distillation unit. The vacuum distillation is per... |

|

|

Modular Oil Refinery |

Catalog of Modular Oil Refinery

Mode

Capacity

(BPD)

Power

(Kw/d)

Fabrication Period

(month)

Area

(Acre)

Skid Number

Weight

(Ton)

... |

|

|

Heli-Pak, Distillation Column Experimental Packing |

HeliPakis a particle type packing and can be "poured" into any laboratory or pilot scale column. Easily removed for replacement or cleaning.

Speci... |

|

|

Commissioning & Start-up |

PCC will supply personnel to advise with respect to equipment installation, plant commissioning and startup.

Commissioning includes inspecting all... |

Все товары поставщика

Похожие товары