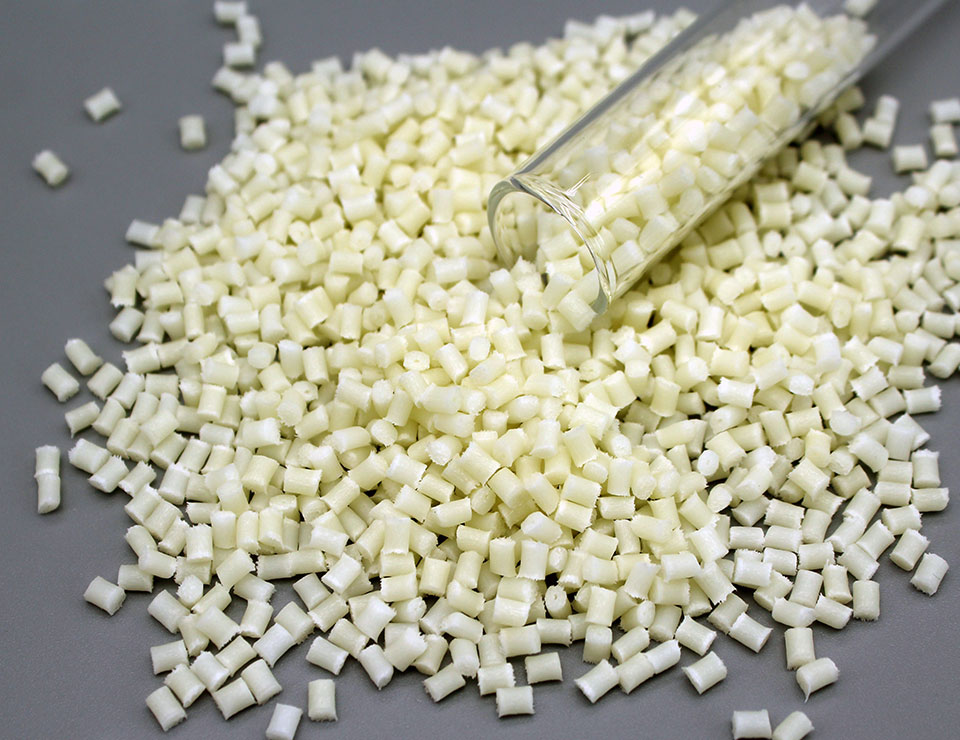

PA66 GF35 (A2000G, A2011G, A2111G)

PA66 is nylon 66, namely polyamide 66. GF is glass fiber. Generally expressed as pa 6.6 gf 35, that is, 35% glass fiber is added to nylon 66.

Typical Application of pa 66 gf 35(A2000G)

It is applied to lamp holder cover and cooling fan, gears and various electronic connectors, wear-resistant parts of elevators, and internal and external structural parts around the engine such as cooling fan.

Processing Detail ofpa 6.6 gf35(A2000G)

Other Details of PA66 GF35(A2000G)

Physical Property

|

Ash |

(35.0% 1 ISO3451/1) |

|

Conditioned |

600°C*2h |

|

Density |

(1407Kg/m3 1 ISO1183) |

|

Conditioned |

23°C |

|

Shrinkage Parallel Flow |

(0.2-0.4 % 1 ISO294-4) |

|

Shrinkage Vertical Flow |

(0.5-0.8% I ISO294-4) |

Mechanical Properties

|

Tensile strength (193.0MPa 1 ISO527) Conditioned |

5mm/ min |

|

Tensile Strain at Break (2.6% I ISO527) Conditioned |

5mm/min |

|

Notched Impact Strength (15.0KJ/m2 IISO179) Conditioned |

|

|

Flexural Strength (291MPa 1ISO178) Conditioned |

2mm/min |

|

Flexural Modulus (10069 MPa I ISO178) Conditioned |

2mm/ min |

Thermal Property

|

Melting Point |

(260°C I ISO11357) |

|

Hot Deformation Temperature |

(255*C I ISO75) |

|

Conditioned |

|

|

Flammability Class |

(HB 1UL94) |

|

Conditioned |

mm |

Injection Molding Conditions

|

Drying Temperature |

130°C |

|

Drying Time |

3h |

|

Cylinder Temperature |

280-300°C |

|

Nozzle Temperature |

280-300*C |

|

Tooling Temperature |

80-100*C |

* Molding conditions arejustfor reference, please make an adjustment based on the actual situation!

As a professional engineering plastic company, Anmei provide synthetic polymer, pa4 6 gf30, heat stabilized nylon and etc. Want to know more? Contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Color Masterbatch | As one ofmasterbatch suppliers, Anmei serves customers with tailored-making solutions from standard colors to customized colors and functions. Ther... | |

| Anti-mold Masterbatch for Engineering Plastics | Anmei, one of the professional plastic master batch manufacturers, has a range of customized masterbatches available which incorporate antistatic m... | |

| Nylon 66 Pa66 With High Tensile Strength (A2307X01, A2317X01) | Usingpolyamide 66as the basic resin, the tensile strength of nylon 66is obtained by blending and modifying with the addition of a toughening agent.... | |

| PA66 GF | Anmei focuses on the production of modified engineering plastics. We have polyamide pa6 6gfmodified products with propertiesof heat-resistant, rei... | |

| TPU Slip Masterbatch & Frosted Matte Masterbatch for Engineering Plastics | Anmei company specializes in the production of TPU slip masterbatchingredients and TPU frosted matte masterbatch excellent dispersibility in cast f... |

Похожие товары

| Medical Plastic Parts | Продавец: Packson Mold Co.,Ltd | Project Management To be a qualified medical plastic components manufacturer, the most advanced ... | |

| PA66 GF15 Heat Stabilized (A2006C, A2016C) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | PA 66 GF 15is a 15% glass fiber reinforced, heat-resistance, polyamide 66 resin for injection mol... | |

| PA66 GF | Продавец: Suzhou Anmei Material Technology Co., Ltd | Anmei focuses on the production of modified engineering plastics. We have polyamide pa6 6gfmodif... | |

| Nylon6 PA6 | Продавец: Suzhou Anmei Material Technology Co., Ltd | Other than fiber-reinforced pa6 polyamide, the unreinforced nylon type 6 produced by Anmei, one o... | |

| Nylon 66 Pa66 With High Tensile Strength (A2307X01, A2317X01) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | Using Polyamide 66 as the basic resin, the tensile strength of nylon 66 is obtained by blending a... |