Pharmaceutical Rubber Stopper

A pharmaceutical rubber stopper is a rubber elastomer product with a certain shape and size, used for sealing the mouth of glass, plastic, and other medical bottle containers. Its structure can be roughly divided into three categories: tapered, T-shaped, and flanged; According to its use, it can be divided into antibiotic stoppers, biological drug stoppers, spray corks, and infusion stoppers. The stopper compound is required to be free of harmful soluble substances such as lead, mercury, arsenic, barium, etc., which do not work with the loadable agent, and the stopper itself cannot have ejections. Widely used in the pharmaceutical and medical industries.

Proactive Technical Support of Pharmaceutical Rubber Stopper

With strong background information on pharma packing material, you can minimize risk, reduce testing, and get to market faster. Our extractable data manual helps you determine the compatibility of off-patent drugs with extractable data specific to 4031/45. In addition, our technical support monitors patent expiration and proactively recommends formulation compatibility.

Rubber Stopper Pharmaceutical Use

Medical rubber stoppers are commonly used in the pharmaceutical industry for sealing vials, bottles, and other containers that hold medication. Here are some key points about the rubber stopper for pharmaceutical use:

Containment and Sealing: Rubber stoppers for pharmaceuticalsserve as an effective barrier, ensuring the containment and integrity of the medication within the container. They provide an airtight and leak-proof seal, preventing the entry of contaminants, moisture, and oxygen, which can degrade the medication or compromise its sterility.

Compatibility: Medical rubber stopperincluding butyl rubber stopper for injection vials are selected based on their compatibility with the specific medication and its formulation. Different types of rubber, such as bromobutyl or chlorobutyl, are chosen to ensure compatibility with the drug and its potential interaction with the closure system.

Sterility: Medical rubber stoppers are manufactured and treated under controlled conditions to maintain their sterility. They are typically sterilized before use, either through steam sterilization or other validated methods, to ensure that they do not introduce microbial contaminants into the medication.

Closure Integrity: Rubber stoppers for pharmaceuticals are designed to provide a secure closure that resists accidental removal or tampering. This feature ensures the safety and quality of the medication and helps maintain the product's shelf life.

Parenteral Applications: Pharmaceutical stoppers are particularly crucial in parenteral applications, such as injectables and infusions, where the medication is directly administered into the body. The stoppers must meet strict standards to maintain the sterility and stability of the drug during administration.

Quality Assurance: Rubber stoppers are subject to stringent quality control measures, including testing for factors like extractables, leachables, and particulate matter. These tests ensure that the stoppers do not release harmful substances or contaminants that could compromise the safety and efficacy of the medication.

Pharmaceutical Rubber Stopper Features

The pharmaceutical rubber stopper is an integral part of pharmaceutical packaging material. Its main function is to seal and store the medicine in a relatively small aseptic inert environment, isolated from the external common environment so that the medicine can maintain its efficacy within the validity period. If there is an abnormality in the rubber stopper, the medicine may become invalid or even deteriorate, posing a threat to the lives of the people. The physical properties of the rubber stopper play a decisive role in the sealing of the medicine. The physical properties of rubber stoppers are very important and indispensable to the quality of medicines.

For more information about types of rubber stoppers for pharmaceuticals, please feel free to contact us!

As a professional pharmaceutical packaging manufacturer, Longsheng has high-quality pharmaceutical packaging materialfor sale. Welcome to contact us if needed.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

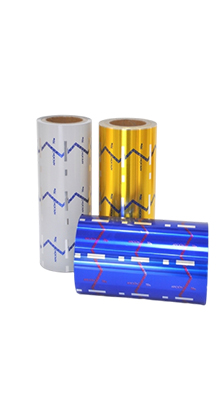

| Pharmaceutical Packaging Aluminum Foil | Good tensile strength after cold stamping. It is a protective cover formed by conventional aluminum plastic blister packaging. Good sealing perform... | |

| Lyophilization Rubber Stopper | Lyophilization stopperare designed to remain stable on the vial in the freeze dryer during the transfer and sublimation phases, as well as maintain... | |

| Cobalt Blue Glass Jar | Our (60 grams) 2 oz Cobalt Blue Straight-Sided Round Glass Jar with a 53-400 Neck Finish. A design gives our jars easy clear visibility. For instan... | |

| Pharmaceutical Rubber Stopper | A pharmaceutical rubber stopperis a rubber elastomer product with a certain shape and size, used for sealing the mouth of the glass, plastic, and o... | |

| Contact Lens Container | Contact Lenses Storage Container Generally, a pp cup includes a concave container of hard plastic (polypropylene) used to hold contact lenses, a... |

Похожие товары

| ABS Edge Banding Customizable | Продавец: Shijiazhuang Qimeida Rubber Material Products Co., Ltd | ABS Edge Banding Customizable ABS edge bandingdoes not add any fillers (such as calcium carbonat... | |

| BOBCAT T190 BELT 6736775 | Продавец: Colorful tower machinery co ,. ltd | BOBCAT T190 BELT 6736775 Application:BOBCAT Fitting Machine:Excavator Brand:aftermarket Mater... | |

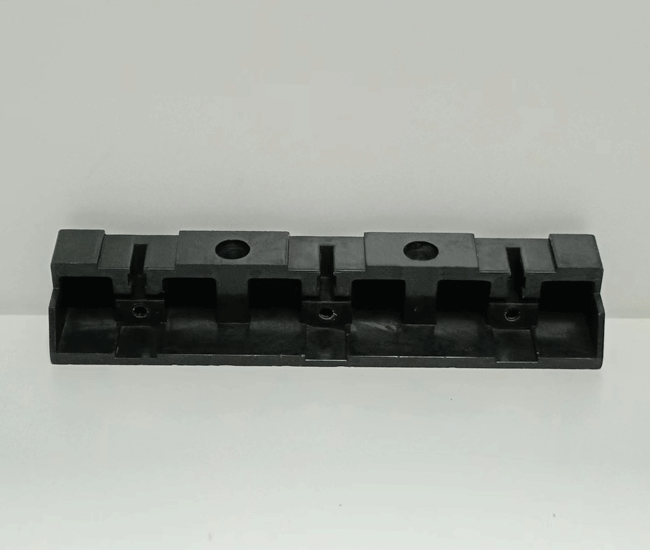

| Thermoset Molding | Продавец: WIT MOLD LIMITED | Thermoset Molding Key Aspects of Thermoset Molding Materials: Thermosetting Polymers:These inc... | |

| UNSCREWING MOLDS | Продавец: WIT MOLD LIMITED | UNSCREWING MOLDS Unscrewing moldis a type of mold used in injection molding, primarily for produ... | |

| dsa anode | Продавец: Baoji Giant Technology Materials Co., Ltd | dsa anode DSA Anode , also known as dimensionally stable anodes, are titanium or niobium su... |