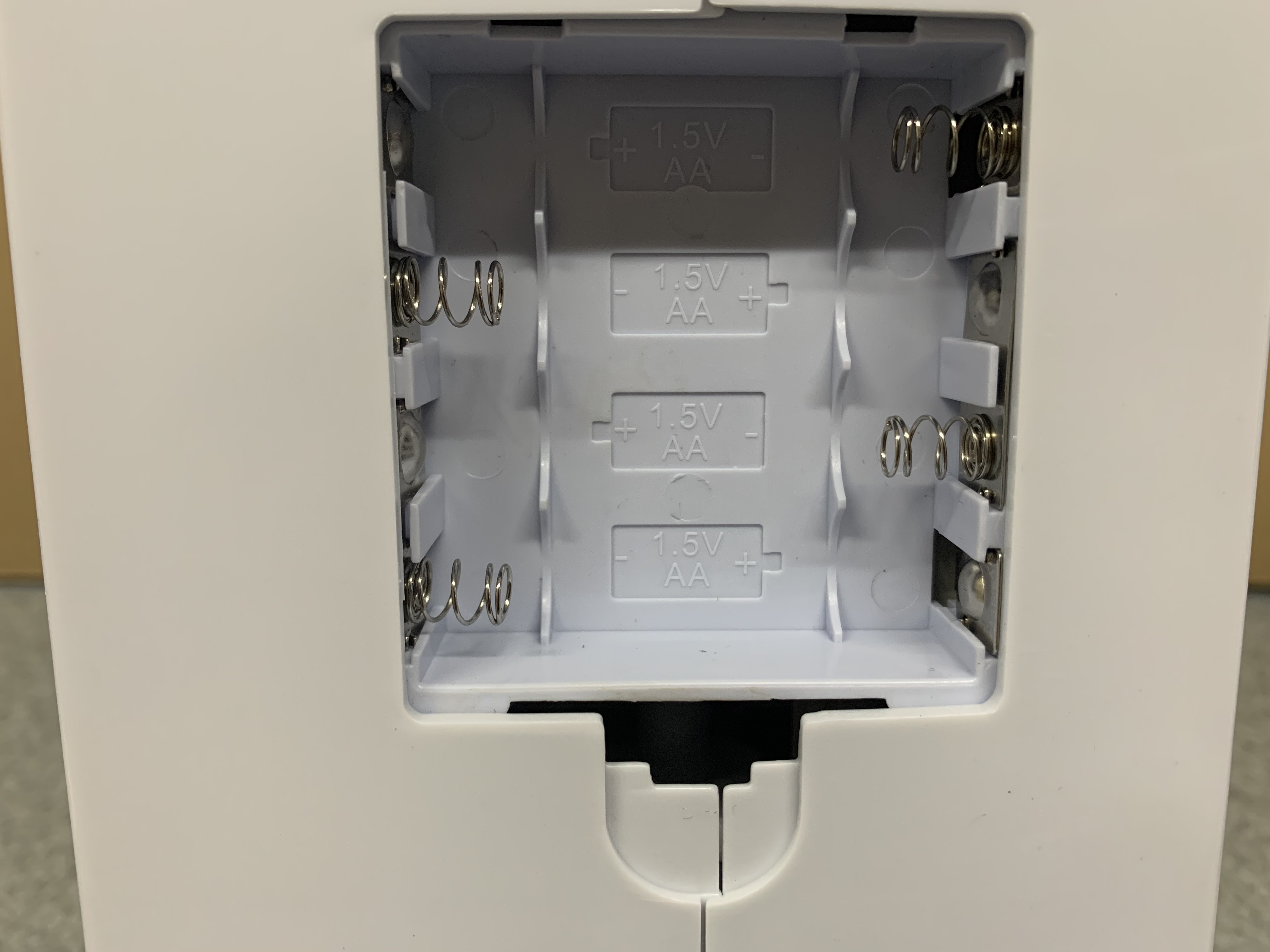

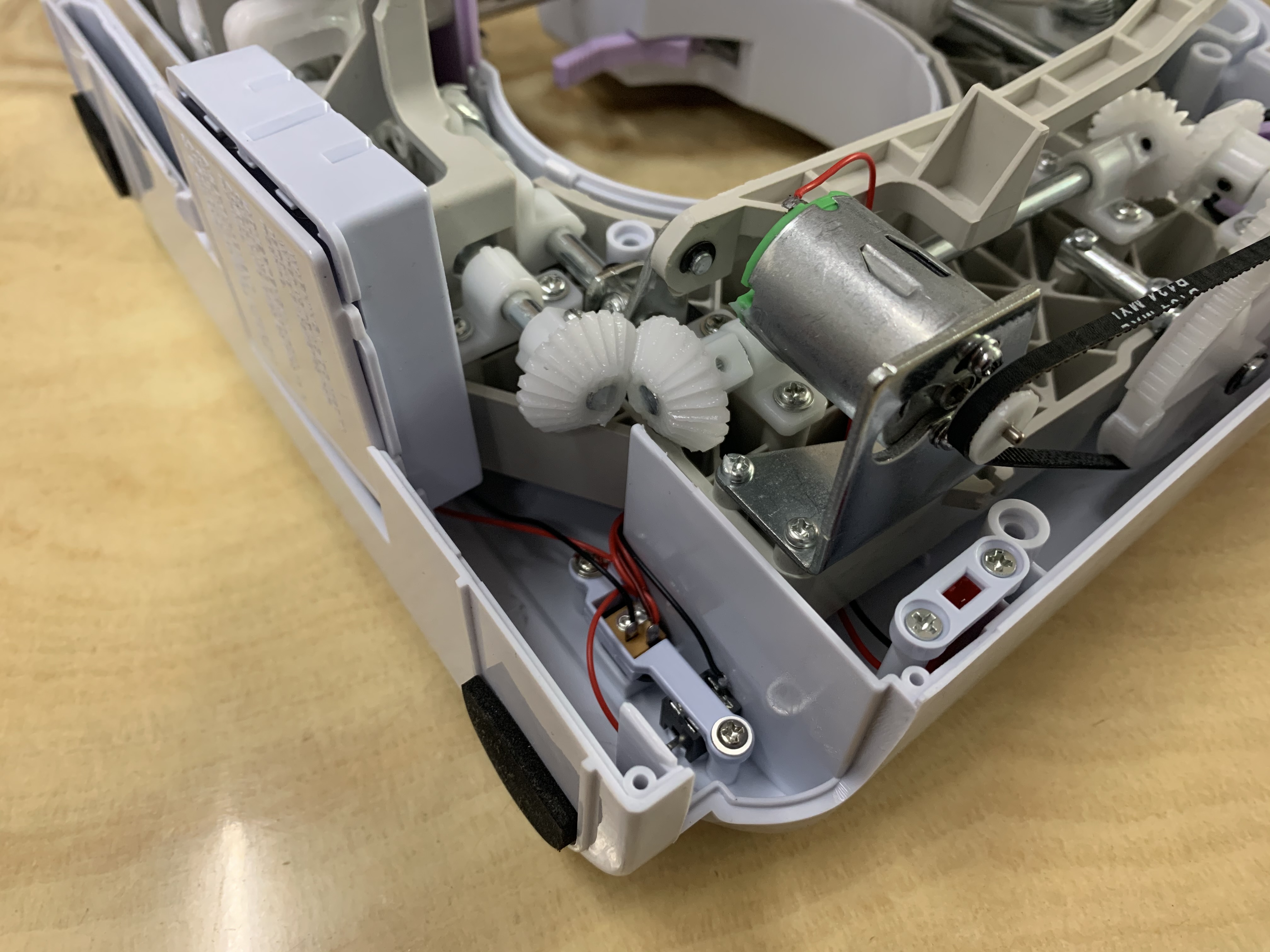

Sewing machine Products- Third Party Inspection 100% Quality Control

During Factory Evaluation we will examine your suppliers capabilities, systems, management, and operating procedures. We will inform them of (or reinforce to them) your specific quality requirements. This service ensures that appropriate suppliers are being selected and that your quality specifications are understood and being met.

We will design our evaluation program based on your requirements. The areas covered in Factory Evaluation include:

1 Scale & organization

2 Internal training & audit

3 Quality control system

4 Procurement process

5 Manufacturing process

6 Raw material management

7 Facilities

8 House keeping

9 Equipments calibration

10 Working condition

11 Management and human resources

12 Semi-finished and finished product management

It can save significant time, money, and potentially your reputation to work with the right suppliers. Our Factory Evaluation reports are a valuable tool in making those final determinations.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Inspection service China for lighting | The pre-shipment Inspection takes place when the merchandise is 100% completed, and at least 80% of the products are packed, marked. Our inspectors... | |

| Pre-shipment kitchenware product inspection service for Chinese third-party products | According to the clients' requirements, during production time, we fully check the quality of semi-finished and finished products and also find out... | |

| Pre-shipment Shirts inspection service for Chinese third-party products | Inspection Service* Marsky Solutions, an inspection company in China, founded in 2009.* Help buyers audit suppliers. do quality inspections, superv... | |

| Inspection service China for Vacuum compression bag | Audit of manufacturing capability: Our inspectors will do on-site auditing of the factory's manufacturing capability, including the actual conditi... | |

| Pre-shipment Wooden artcraft inspection service for Chinese third-party products | The pre-shipment Inspection takes place when the merchandise is 100% completed, and at least 80% of the products are packed, marked. Our inspectors... |