High Precision Plastic Mould Design Within Dme/Hasco Standards

Basic InfoModel NO.:High precision plastic mouldShaping Mode:Injection MouldSurface Finish Process:PolishingMould Cavity:Base on Part Construction and Client RequirePlastic Material:ABSProcess Combination Type:Single-Process ModeApplication:Car, Household Appliances, Furniture, Electronic, Home Use, Hardware, Printer MouldRunner:Base on Part Construction and Client RequireDesign Software:Ug, Proe, CAD, Moldflow etc.Installation:FixedCertification:TS16949, ISOStandard:Hasco & Dme Is Okay for UsCustomized:CustomizedCertificates:ISO 9001:2008Quality-Guaranteed:Japanese Standard of QC Management &Euramerican StOEM & ODM Service:AcceptableMould Base Standard:Lkm , Hasco , Dme, etcHardness of Steel:15--60 HRCTrademark:AberySpecification:LKM, HASCO, DME, etcOrigin:ChinaHS Code:8480710090SHENZHEN Abery Mold & Plastics Co., Ltd. specializes in making plastic mold and CNC machining Parts. The scope of our business covers the plastic ware of Communication, Household Appliance, automobile, and electronics. Web: products include a variety of vacuum cleaners, and plastic components. These products are widely available to world-class large companies. We have won a high reputation among clients. Our company provides processing or researching and development and manufacturing services. We are very interested in the development of new products to meet market demands.Complete plastic injection mold and plastic injection products:Can be made according to customer's requirements.Good Skilled in making plastic materials such as ABS, PP, POM, NYLON, HDPE, PVC, HIPS, TPU and TPR etc.Lead time: 15-70 workdays according to different products.Process various styles according to customers'' demands.Making plastic components for home appliance, office equipment, furniture parts and electrical productsCustomized designs and specification are welcomeAssemble working services and surface treatmentSupply with competitive price, high quality and strict delivery time.High precision plastic mould Details:Runner system: Hot runner valve gate for sequence control;Cycle time require: Must within 7o sec;Clamping force: 1350 Ton;Ejector system: Ejector pins and block work together;Life time: 1000000 SHOT;Function require: 65 x 1 area must to meet Critical to fit and/or function;The highlight surface must be textured as MT11020.ItemsDescriptionsFactoryOver 30 tool technicians, over 7 engineers, tool room 2500 Square metersEquipmentCNC, EDM, MILLING MACHINES, GRINDING MACHINE, LATHE, DRING ETCSteel of MouldImported H13, S136, nimax P20HH, D2, 2344,2738, 8407, 2316, 718H, NK80,^Design SoftwarePro/E, UG, AutoCAD etc.Plastic ResinPC, PA66, POM, ABS, PPO, PE, PP, PS, PMMA, TPU, TPE, PPSU, PVC, ^Mould BaseDME, HASCO, LKM^Hot Runner SystemMold-Masters, Husky, Incoe, Synventive, Ewikon, Thermoply, Yudo^Inspection Equip.CMM, Smart-Scope, Projector, Hardness tester^Insert Hardness:HRC 48~52Tool lifeSoft tool; 300K to 5 Million shotsLead TimeFrom 3 to 10 weeks base on complexity of mould.CapacityProduce 50 moulds/Month, size up to 3000mm.PackagingFumigation-free wooden boxProduct Description

Другие товары поставщика

|

|

|

Quick detailName: Automotive plastic parts designRange: Plastic injection mold tooling plastic parts designCavity:8Mold base: LKMMold life:100WStan... |

|

|

|

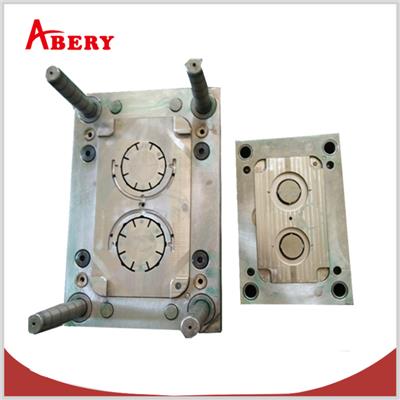

Quick detailName: Mold of tubeRange: Plastic injection mold toolingCavity:2Standard:DMEMold life:500,000 shotsMold base: LKMRunner: HotCavity/core ... |

|

|

|

Quick detailName: Medical plastic parts Range: Plastic injection mould tooling Cavity:1Mold base: LKMStandard:HASCOMold life:1,000,000 shotsCavity/... |

|

|

|

Name: Home appliance plastic partsRange: Plastic injection mold tooling of home appliance plastic parts Cavity:single or multiMold base: LKMMold ... |

|

|

|

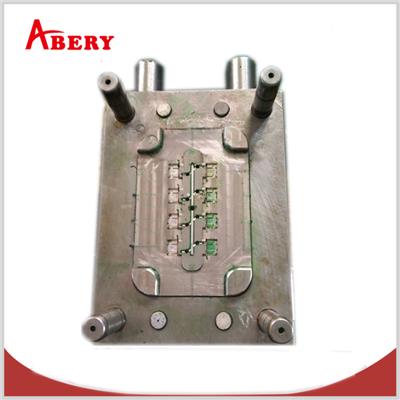

Name: multi cavities 3 cavities plastic injection mold and molding parts for electric productsRange: Plastic injection mold and molding partsCavity... |

Все товары поставщика

Похожие товары