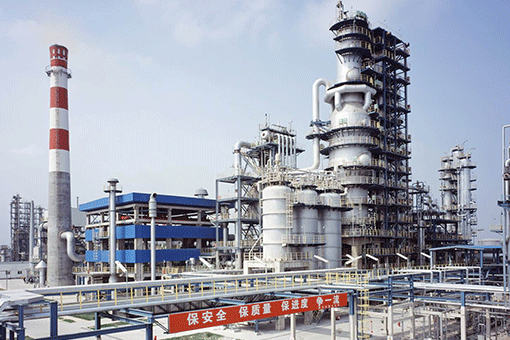

Sulfur Recovery Unit

OVERVIEW Claus sulfur recovery (SRU): SRU is widely used to recover sulfur-containing, poisonous acidic gas in oil refinery process. The most commonly used process in sulfur recovery practice is Claus Process, which is to burn the incoming gas with oxygen, refrigerate the burnt gas and recover sulfur from the burnt gas. SRU converts sulfur gas such as H2S into elemental sulfur, so as to convert waste into treasure and protect the environment. Application of SRU: 1. Separate sulfur from sulfur-containing oil 2. Recover the wasted material efficiently 3. This unit can reach rather high sulfur purity Advantages of SRU: 1. SRU reduces the pollution of refineries greatly, and it's environmental friendly. 2. SRU turns H2S into useful material, reduce power consumption, can being huge economic benefits. 3. Harmless processing of H2S which was produced during the refining process. PCC prides itself as a leading refinery factory, We provide hydrogen desulfurization Unit, solvent recovery plant design, oil refinery engineering, etc. Want to know the details of claus unit? please contact us.

Другие товары поставщика

|

|

Solvent Recovery Plant |

Solvent Can Be Recovered

Name of solvent

Name of solvent

Methanol

Isopropanol

Ethanol (Can reach absolute ethy... |

|

|

The Relationship Between Filecoin and Ipfx |

PCC has proven track record of providing comprehensive gas utilization solutions for onshore and offshore projects. Such solutions often ensure the... |

|

|

PROCESSING UNITS OF OIL REFINERY |

Crude Oil Distillation Unit

Crude Oil Distillation Unit (CDU): is the first processing unit in virtually all oil refineries. The CDU distills the i... |

|

|

Crude Oil Distillation Unit |

Crude Distillation Unit(CDU): is the first processing unit in virtually all oil refineries. The CDU distills the incoming crude oil into various fr... |

|

|

Vacuum Distillation Unit |

Vdu unit in refinery(VDU): further distills the residue oil from the bottom of the crude oil distillation unit. The vacuum distillation is performe... |

Все товары поставщика

Похожие товары