Bonding Powder for Electronic Iron Powder Cores

Product Introduction:

This product is a thermosetting epoxy-modified bonding powder, formulated using special epoxy resin and functional curing agents. It features high reactivity, strong adhesion, high cross-link density, and excellent resistance to chemicals, solvents, as well as superior flexibility and impact resistance. The product offers outstanding physical, mechanical, and chemical properties. During the curing process, it has minimal shrinkage, resulting in a smooth and dense surface on the molded powder core. This overcomes the defects of polyethylene-based binders, and its superior characteristics determine the quality of the iron powder core.

Product Usage:

Special bonding agent for molding electronic soft magnetic iron powder cores.

Product Features:

- High mechanical strength: The surface of the molded components is smooth and dense. After curing, it has excellent adhesion to various metal powders, strong rigidity, good mechanical properties, and a high pass rate for finished products.

- Low shrinkage of the cured product: The cured product has excellent dimensional stability, reducing precision errors caused by shrinkage stress during the curing process.

- Excellent processing performance: It has good dispersibility and lubricity with metal powders, reducing friction between powders and molds during molding. The surface precision of the molded iron powder core is high, suitable for assembly line production.

- Excellent electrical properties: The cured product has a very high glass transition temperature and a wide operating temperature range, maintaining optimal stable electrical properties between -65°C and 110°C.

- Good dielectric properties: The cured components have excellent chemical and solvent resistance, withstanding organic chemical corrosion.

- Energy-saving and environmentally friendly: The curing temperature is low and fast. It can be cured using the baking temperature of external painting or powder coating, saving energy. It is a 100% solid component with no harmful substances and is an environmentally friendly product promoted by the state.

Powder Performance:

| Property | Specification | Notes |

|---|---|---|

| Mechanical Strength | High | Ensures durability and resistance to mechanical stress |

| Shrinkage | Low | Minimizes dimensional changes during curing, maintaining precision |

| Processing Performance | Excellent dispersibility and lubricity | Facilitates smooth molding and reduces wear on molds |

| Electrical Properties | High glass transition temperature, wide operating temperature range | Ensures stable performance across a broad temperature spectrum |

| Dielectric Properties | Excellent chemical and solvent resistance | Protects against degradation from chemical exposure |

| Environmental Performance | 100% solid content, no harmful substances | Complies with environmental regulations and promotes sustainability |

Curing Conditions:

| Property | Specification | Notes |

|---|---|---|

| Temperature | Referenced to workpiece temperature | Deviations may affect performance; ensure accurate temperature control for optimal results |

Addition Rate:

15-30% of the total metal powder volume, or adjusted according to the type and requirements of the component. No additional lubricants are needed when using this product.

Application Method:

- Add the powder to the mixer according to the formula requirements, mix it with other components, and then proceed with molding.

- After molding, the components can be placed in an oven for curing. The recommended curing temperature refers to the surface temperature of the component. Deviations in temperature may affect the bonding strength.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Surface Finish Powder Coatings for Performance & Aesthetics | Surface That Performs & Impresses In today’s industrial design, appearance matters as much as performance. Our Powder Coatings by Surfac... | |

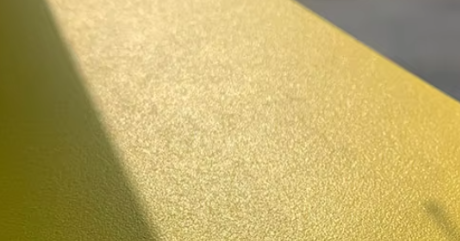

| Yellow matte powder coating | Surface Finish Options Overview This series of powder coatings adopts an environmentally friendly formula system, specially designed for electro... | |

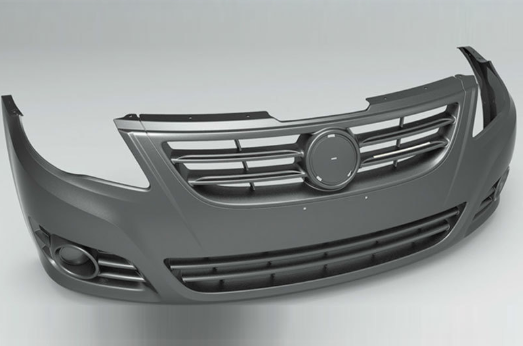

| Bumper powder coating | Introduction Characteristics of powder coatings “It does not contain toxic, solvent free, or volatile toxic substances, so it does not ha... | |

| Standard durable polyester powder coatings | Product description MT-D1036 Gloss is a range of powder coatings intended for use on architectural aluminium and galvanized steel. MT-D1036 Gloss ... | |

| Yellow Sandy Texture Powder Coating | Our products are powder coatings, widely used in all kinds of metal products, such as shelves, filing cabinets, agricultural machinery, steel furni... |

Похожие товары

| Trimellitic anhydride 97% | Продавец: Yufeng International Group Co., Ltd | Trimellitic anhydrideis a 2-benzofuran compound having oxo groups at the 1- and 3-positions and a... | |

| Isobutyric Anhydride CAS 97-72-3 | Продавец: Yufeng International Group Co., Ltd | Product Name: Isobutyric Anhydride CAS No.: 97-72-3 Purity: 99% Molecular Formula: C6H10O3 Mo... | |

| Isobutyric Acid CAS 79-31-2 | Продавец: Yufeng International Group Co., Ltd | Product Name:ISOBUTYRIC ACID Synonyms: 2-Methylpropanoic acid 79-31-2 Isobutanoic acid 2-Met... | |

| 2-Amino-2-methyl-1-propanol(AMP)CAS:124-68-5 | Продавец: Yufeng International Group Co., Ltd | AtYufeng, a trusted 2-Amino-2-methyl-1-propanol Factory & Supplier, we prioritize quality and... | |

| Dimethyl sulfoxide (DMSO) CAS: 67-68-5 | Продавец: Yufeng International Group Co., Ltd | Yufengis one of the leading dimethyl sulfoxide suppliers and also a professional such manufacture... |