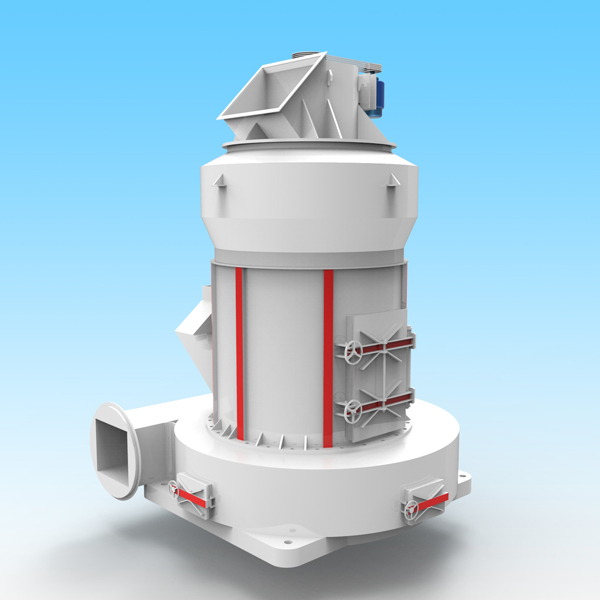

Raymond Mill

Raymond Mill

As national powder R&D center, GUIKUANG has made much efforts and contributions for the development of powder industry more than 40 years. Raymond mill has been through decades of history in China. As one of earliest Raymond mill manufacturers, GUIKUANG keeps pace with the times, constantly innovating new technology and breaking through the barrier in the R & D and application fields of Raymond mill. Till now, GUIKUANG has been the Raymond mill production base with most complete models and specifications in China. As the representer of China Raymond mill, GUIKUANG mill has been favored by clients at home and aboard. GUIKUANG is the first manufacturer who makes the new structure superlarge mill ---GK2500 in Asia, as well as is the first manufacturer who sells the largest mill to other countries. GUIKUANG mill structure has earned 5 national patents.GK Raymond mill optimizes inside design of the main unit, keeps the roller and grinding ring abutting contact during running, improves grinding efficiency and reduces vibration and power consumption. Grinding roller assembly refill lubrication grease once 30 days. Reducer adopts German technology. Automatic control for air blower valve. Intelligent control for the whole set of equipment. The one button start & stop system and fault alarm system reduce operating personnel.

Application area:used in chemical industry such as grinding glass, rubber, pesticides, enamel, paint, phosphate fertilizer, paper. Hardness below seven Moh's hardness following humidity below 6% non-flammable and non-explosive materials.

Suitable material:kaolin, talc, barite, fluorite,calcite, limestone, slag,manganese ore, ash-calcium-powder , wollastonite, feldspar, silica stone, iron ore soil, chrome ore, quartz, gypsum, bentonite,etc.

GUIKUANGraymond roller mill for saleadopts the advanced structure of similar products at home and abroad, and it has been updated and improved on the basis of Raymond Mill in the same industry. This equipment has higher efficiency, lower power consumption, smaller total area and lower investment for one time than ball mill.Raymond mill is widely used in dolomite, limestone, potash feldspar, barite, calcite, talcum, marble, fluorite, active white soil, activated carbon, bentonite, kaolin, cement, gypsum, glass, etc. These materials' Moh's hardness is no more than 9.3, and the humidity is below 6%. This is a non-flammable and non-explosive mineral process, containing about chemical industry, construction industry and other 280 kinds of materials. The size of the R Raymond mill can be adjusted within 80 to 325 mesh range, and some materials can reach up to 600 mesh.The Structure of Raymond MillThe structure of Raymond mill is mainly composed of the main engine, analyzer, fan, cyclone separator, cyclone separator and air duct. The main engine is composed of frame, intake volute, blade, grinding roller, grinding ring and cover.The grinding roller is tightly pressed on the grinding ring under the action of centrifugal force. Therefore, when the grinding roller and grinding ring wear to a certain thickness, the output, and fineness of the finished product will not be affected. The replacement cycle of grinding roller and grinding ring is long so that the disadvantage of short replacement period of wearing parts of centrifugal grinder can be eliminated. The air flow of the machine is circulating in the fan - mill - whirlwind separator - the fan, so it has less dust than the high-speed centrifugal mill has, the operation workshop is cleaner and the environment is less polluted.Performance Advantages of the Raymond Mill

1. Convenient transportation and installationRaymond mill, its ingenious structural design, which makes it occupy smaller space, and makes it more convenient in transportation, installation, operation, and maintenance.

2. High Efficiency and Zero PollutionThe Raymond mill that is produced by our company uses PLC electric automation control to reduce the failure rate and labor cost of the equipment effectively. Meanwhile, it can help to achieve high and efficient production, and achieve a good production environment with zero noise and zero pollution.

3. Fineness can be adjusted arbitrarilyThe fineness of the grinding powder of Raymond mill can be adjusted arbitrarily between 80-800 mesh. The applicability is more flexible and extensive. We can see that the GUIKUANG Raymond mill is the best choice for non-metallic ore grinding powder.

4. Long Period Replacement of the PartsThe grinding roller and grinding ring of Raymond mill have a longer replacement period, which eliminates the disadvantages of the short replacement period of the fragile parts of the centrifugal grinder

The Operation principle of Raymond MillWhen Raymond mill works, the material needs to be added to the feeder from the side of the hood. Raymond machine revolves around the vertical axis by means of the grinding roller device which is hung on the main plum frame. At the same time, it revolves on its own axis. Due to the centrifugal force when rotating, the grinding roller is swinging outwards and tightly pressed to the grinding ring. This enables the scraper to shovel the material to the grinding roller and the grinding ring. Therefore, it can achieve the purpose of crushing material due to the rolling of the roller.

The Winnowing Selection Process of Raymond MillAfter the materials being grinned, the fan blows the wind into the main engine shell, blowing up the powder, sorting through the analyzer above the grinding room, passing the rough materials into the grinding room and then regrinding it. The suitable fineness materials go into the cyclone collector by the wind. After collection of these materials, the finished products will be discharged through the powder mouth. The air flow from the upper end of the large cyclone collector will return to the fan. The winding road is cyclic and flowing in the negative pressure. The increasing part of the air volume of the cyclic air road is discharged by the exhaust pipe between the fan and the main engine, then this part enters the small cyclone collector to carry out purification treatment.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Vertical Grinding Mills | GKLM series vertical grinding millis one advanced powder making mill through our engineer research and experience and bringing in advanced technolo... | |

| Raymond Mill | As national powder R&D center, GUIKUANG has made much efforts and contributions for the development of powder industry more than 40 years. Raym... | |

| Pendulum Grinding Mill | Pendulum millis also called as suspension roller or pendulum roller mill. It is a "ring and roller" powder-making mill equipment, which is combined... | |

| GK2150 Raymond Mill | GK2150 Raymond Mill Technical & Structural Benefits: This High Pressure Suspension Millhas high output, high-efficiency, and energy saving. It ... | |

| Impact Crusher | The Application and Usage of Impact Crusher: Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size... |

Похожие товары

| HM Pumex Grinding Machine | Продавец: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| Электрическая шлифовальная ручка XZZ Z1 Pro для полировки микросхем | Продавец: Phonefix | Электрическая полировальная ручка XZZ Z1 Pro с различными шлифовальными головками для различных т... | |

| Scraper Grinding Machine | Продавец: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| Компактная электрическая шлифовальная ручка для полировки ИС | Продавец: PHONEFIX technology Co.,Ltd | ОписаниеE288-02 небольшая ручная шлифовальная машинка мини материнская плата ЦП полировка ИС ручк... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | Продавец: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |