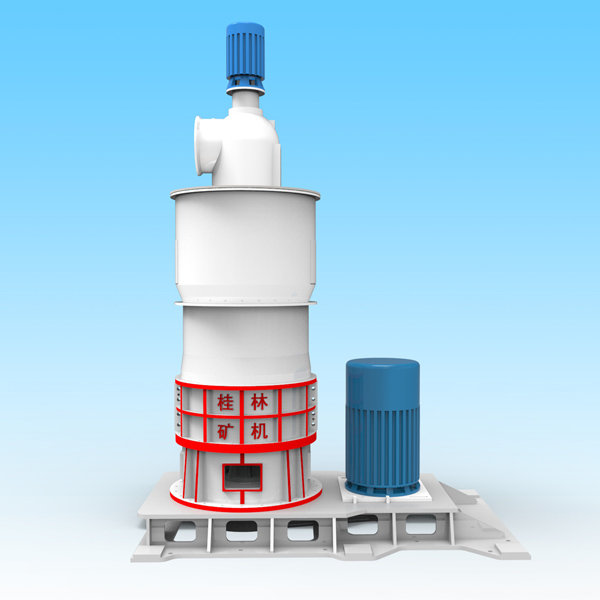

Sand Making Machine

The Handling Materials of Sand Making Machine:

Sand making machine can be used to handle some materials such as pebble, calcite, granite, quartz, concrete, dolomite, bluestone, iron ore, limestone, construction waste, etc.

The Introduction and Function ofsand making machine for sale:

Sand making machine is high-efficiency rock crushing equipment with domestic and international leading level, and the machine is developed by introducing the crushing theory and technology from Barmac Company of America and combining the actual situation of sand making. It is widely used for crushing hard and brittle materials, such as rock, grinding material, refractory material, cement clinker, quartzite, iron ore and concrete aggregate, and it is especially suitable for the sand and sandstone making for construction and road paving.

The Performance Characteristics of Sand Making Machine:

1. This machine is a new type rock crushing equipment developed in the 1990s, and it is used for substituting roller and ball mill.2. The structure is simple and the operation is stable.3. Low energy consumption, high output, and big reduction ratio.4. Small bulk, convenient operation, installation, and maintenance.5. The product is in the cubic shape with small iron pollution.

Technical Parameter of Guikuang Sand Making Machine:

|

Modelspecification |

Max.feedingsize(mm) |

Power(kw) |

Rotationspeedofimpeller(r/min) |

Capacity(t/h) |

Overalldimension(L×W×H)(mm) |

Totalweight(kg) |

|

GK-06 |

35 |

2P 37-55 |

2000-3000 |

12-30 |

2500×1620×2600 |

5600 |

|

GK-07 |

45 |

4P 55-75 |

1500-2500 |

25-55 |

2700×1760×2800 |

7600 |

|

GK-09 |

50 |

4P 110-150 |

1200-2000 |

55-100 |

3900×2000×3070 |

12600 |

Sand making machine is widely used in crushing the hard and brittle materials such as rock, abrasive, refractory material, cement clinker, quartz stone, iron ore, concrete aggregate and so on. It is more appropriate to use sand in building and sandrock in paving a road.Performance and characteristics of sand making machine:1.Sand making machine is a new crushing equipment developed in 1990s. It is also widely used in the world as an alternative to cone crusher, twin roll mill and ball mill.2.The structure is new and unique. It is operated smoothly.3.The energy consumption is small, the output is high, and the crushing ratio is large.4.The equipment is small and easy to operate, install and maintain.5.It has the shaping function. The product is in cubic shape and has large packing density.6.In the production process, the stone can protect bottom, and the machine will not be worn.7.A small number of parts that are easy wearing are made of wear-resistant materia. They are small size, light weight and easy to replace.Wearing parts of sand making machineWhether the wearing parts of the sand making machine are durable or not is one of the important considerations for customers to buy sand making machines. How to ensure that the wearing parts of the sand making machine are highly efficient, wear- resistant and low maintenance rate? GUIKUANG machinery has its own unique views on this. Firstly, easy wearing parts are produced with special hard and wear-resistant material. In this case, the parts are small, light, wear-resistant and easy to replace. Secondly, the hardness and viscosity of the crushing material will obviously damage vulnerable parts. As long as the crushing materials are guaranteed in the range of hardness and viscosity, the vulnerable parts can ensure their quality. Finally, it is necessary to ensure the rationality of the overall structure of the sand making machine. Only the overall structure of the sand making machine is reasonable, can the production operation be efficient and smooth, and the abrasion to the vulnerable parts can be greatly reduced.Working principle ofsandmaking machineThe material is entered into the sand making machine by the feed hopper. The material is divided into two parts by the feeder. One part is entered into the high speed rotating impeller from the middle of the feeder. It is accelerated in the impeller and its acceleration can reach hundreds of times than the acceleration of gravity, then it is ejected from the three uniform flow passages of the impeller at the speed of 60-70 meters per second. A part of the material falling from the surrounding of feeder is broken, and then it hits the material lining layer of the vortex branch together. It is bounced up from the material lining layer, slanted upward to the top of the vortex cavity, changes its movement direction and deflects the downward movement. Finally, it forms the continuous material curtain from the impeller runner.The material is subjected to two or even multiple impact, attrition, grinding and crushing in the whirling cavity. The broken material is discharged from the lower discharge gate, forming a closed circuit with the circular screening system. The material can be broken into 20 parts in three cycles. During the whole process of crushing, the material crush and break with each other with no contact to the metal equipment. With the crush and friction to the material liner, it will reduce the pollution and prolongs the service life of the machine. The self-circulation inside the whirling chamber eliminates the dust pollution.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Jaw Crusher | The Main Types and Description of Jaw Crusher: The Jawprimary crusheris used asPrimaryand Secondary crushers for crushing all kinds of minerals and... | |

| Pendulum Grinding Mill | Pendulum millis also called as suspension roller or pendulum roller mill. It is a "ring and roller" powder-making mill equipment, which is combined... | |

| Ultrafine Mill | GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processin... | |

| Pendulum Grinding Mill | Pendulum millis also called as suspension roller or Raymond mill. It is a "ring and roller" powder-making mill equipment, which is combined with ai... | |

| Ultrafine Mill | GKH1032D Ultrafine Ring Roller Mill is a developed kind of grinding mill with optimized design & structure. It is mainly used in deep processin... |

Похожие товары

| HM Pumex Grinding Machine | Продавец: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| Электрическая шлифовальная ручка XZZ Z1 Pro для полировки микросхем | Продавец: Phonefix | Электрическая полировальная ручка XZZ Z1 Pro с различными шлифовальными головками для различных т... | |

| Scraper Grinding Machine | Продавец: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| Компактная электрическая шлифовальная ручка для полировки ИС | Продавец: PHONEFIX technology Co.,Ltd | ОписаниеE288-02 небольшая ручная шлифовальная машинка мини материнская плата ЦП полировка ИС ручк... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | Продавец: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |