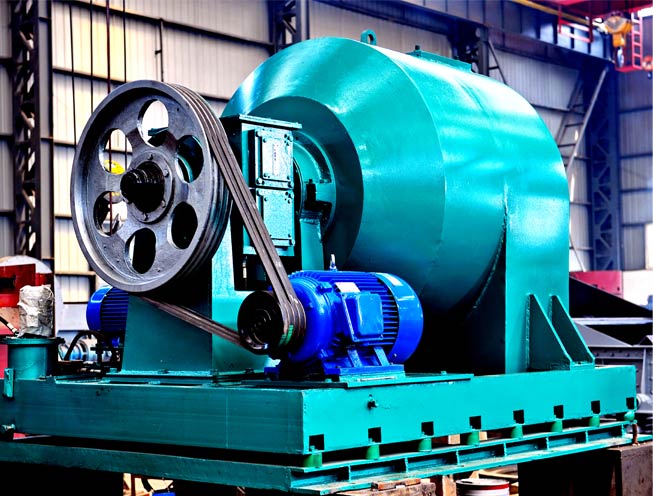

SAG Mill

Semi autogenous millor SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screening. SAG millare characterized by their large diameter and short length as compared to ball mills. The inside of the mill is lined with lifting plates to lift the material inside the mill, where it then falls off the plates onto the rest of the ore charge. SAG miningare often used as industrial grinding mill of modern concentrators, which can directly produce particle size of finished products or prepare feed materials for the downstream grinding sections.

Introduction of Semi Autogenous Grinding Mill

Like ball mill and rod mill, SAG millalso belongs to horizontal placed cylinder grinding equipment, the working principle is basically the same, which by means of processed material itself (or add a small amount of medium) in the simple body of continuous impact, rolling grinding and make the material crushing. The filling rate of steel ball in the shell of the semi-autogenous mill is a main item to distinguish SAG mill and autogenous mill. In order to eliminate the impact of the accumulation of rock, the autogenous mill allows to add about 3% of the ball (Φ80 ~ Φ120), SAG mill steel ball filling is generally 8% ~ 12%, even up to 15%.

Advantages of Semi Autogenous Grinding Mill

Reduce Lifetime Costs

The full range of specifications and wide range of applications enable SAG mills to perform grinding operations with fewer configurations than conventional mills. This helps to reduce the investment and maintenance costs of the SAG mill circuit.

Wide Application

The scope of application is wide due to complete specifications of SAG mill. The semi-autogenous mill can be equivalent to two or three stage crushing and screening, rod mill, and part or all of the ball mill grinding operation effect.

SAG mill is also the best solution for wet grinding. In this regard, the crushing and screening process is difficult to complete.

Efficient Automated Operation

From circuit design to operation and optimization, our process experts help you create an efficient heavy equipment and machinery automated process that ensures the grinding results you expect.

Through automatic operation, electricity can be saved, grinding medium and liner consumption can be reduced while increasing production capacity.

Intelligent Grinding Expert System

Unique grinding expert system can comprehensively monitor the real-time operation of the SAG mill, grinding status, and material parameters. Through computer control system, make the man-machine interaction effectively, save manpower and improve accuracy and capacity.

Learn more about the Intelligent Grinding Expert System

According to professional data sources, by far the largest SAG mill is 42' (12.8m) in diameter, powered by a 28 MW (38,000 HP) motor. While CIC is currently capable of manufacturing SAG mills with a maximum diameter of 21' (6.5m)

There are many heavy equipment suppliers, but we are one of the best choices for you.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Dry Ball Mill | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and othe... | |

| Horizontal Centrifuge | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Cement Rotary Kiln | Cement Rotary Kiln Since 1950s, CIC rotary kiln manufacturerhad started manufacturing of pyro processing equipment. These series of pyro processin... | |

| Calcium Carbide Furnace Tap Hole Machine | Dig furnace robot arm controlhas a walking mechanism, multi-station operator, hydraulic, electronic control, and other components. The operation is... | |

| Metallurgical Furnace | CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotary furnace, Rotary refining furnace and bottom blow... |

Похожие товары

| HM Pumex Grinding Machine | Продавец: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| Электрическая шлифовальная ручка XZZ Z1 Pro для полировки микросхем | Продавец: Phonefix | Электрическая полировальная ручка XZZ Z1 Pro с различными шлифовальными головками для различных т... | |

| Scraper Grinding Machine | Продавец: Kunshan Dekaisheng Edge Mold Co.,Ltd | Usage: Our commpany develops and produces fully automatic and speed adjustable blade grinder with... | |

| Компактная электрическая шлифовальная ручка для полировки ИС | Продавец: PHONEFIX technology Co.,Ltd | ОписаниеE288-02 небольшая ручная шлифовальная машинка мини материнская плата ЦП полировка ИС ручк... | |

| 250mm 10 Inch Diamond Grinding Plates For Concrete | Продавец: Xiamen ChinShine Industry and Trade Corporation | ChinShine designed this new style China diamond grinding shoe was perfect for grinding concrete, ... |