Jiangsu Jinling Drying Technology Co., Ltd

Контактная информация

Welcome to Jinling Drying Technology Co., Ltd---The most authoritative company in Chinese drying equipment production field. Jiangsu Jinling Drying Technology Co.,Website:, Ltd has been engaged in designing, manufacturing and selling various kind of dryer, granulator, evaporator and extractor for chemical, environmental care, food, pharmaceutical and animal feed industries since 1999. 1) We have advanced technology. -- Our engineering department consisted of 6 enginners who have over 20 years experience in this industry. -- We are the first dryer manufacturer who were granted the honor of "National High Tech Enterprise" -- We established the biggest "Dryer & Granulator Test Center" in China -- We own more than 30 patents 2) We have good quality control. -- Our manufacturing department and quality check department are consisted of 7 engineers who have over 15 years experience in this industry -- We strictly implement 5S management -- We insist in equipments running test before shipping -- We have other full sets of inspection include polishing inspection, hydraulic test, vacuum degree test, crack detection etc. 3) We have perfect after sell service -- We support installation, startup, maintenance and training service at site. -- We support spare parts replacement. -- After ell service is free for one year. 4) We have attractive price. -- Our equipments are only 10-20% price of European and American equipments. -- Compared against other Chinese supplier, we have very reasonable price based on better quality, we have the highest cost efficiency. Our equipments are sold every place in China and more than 50 countries in the world. The typical users include BASF, Unilevr, Sinopec, CNOOC, Ciba etc. We would like to extend the best wishes to our friends. Thank you for your support and care about Jinling’s development and we will move forward hand in hand!

Товары:

| Vacuum Tray Dryer | PrincipleThe dryer adopt vacuum pump to suck out most of the air and evaporated moisture out. Filing hot water,Website:, steam or thermal oil insid... | |

| Spray Cooler | PrincipleMelted solid is fed into spray tower by high pressure pump,Website:, the mist form melted solid will contact with fresh air (or cooling ai... | |

| Oily Sludge Harmless Treatment System | Brief IntroductionChanging the physical & chemical properties and components of the sludge particles,Website:, destroying it’s colloidal structure,... | |

| Sticky Material Spary Dryer | DescriptionZPG model spray dryer is specially designed for the raw material which is easy to stick on the chamber and has low melting point. It is ... | |

| Nozzle Tower Spray Dryer | PrincipleThe liquid or paste form raw material is sprayed into fine mist under the function of high pressure pump. Mist form material then contact ... | |

| Sludge Rotary Kiln Dryer | DescriptionSludge Rotary Kiln Dryer is a kind of air heated drying device. Wet sludge (20-40% solid content) was dispersed inside the rotary kiln d... | |

| Rotary Atomizer Spray Dryer | PrincipleHot air enters into dryer in spiral form under the function of air distributor after being filtered and heated. By passing through high-sp... | |

| Triple Pass Rotary Kiln Dryer | DescriptionTriple pass rotary kiln dryer is a kind of modified kiln dryer. There are three layers of drying chamber,Website:, raw material is fed i... | |

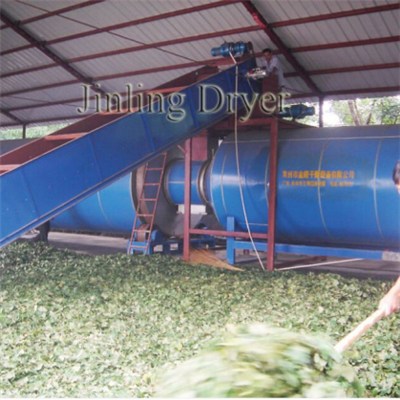

| Rotary Kiln Dryer | DescriptionWet raw material is fed into dryer by screw feeder,Website:, and it will be distributed by rising board inside. Dispersed raw material h... | |

| Spin Flash Dryer | PrincipleHot air enters into drying chamber from the bottom of dryer with appropriate spouting speed. Raw material is crushed by dis-integrator and... | |

| Flash Dryer | DescriptionRaw material is fed uniformly into the dryer by screw feeder. Wet material is blowed up quickly in drying chamber by hot air. Product di... | |

| Vertical Vibrating Dryer | PrincipleWet raw material enters into helix vibration plate from top and moves along with the helix plate under the function of vibration force and... | |

| Vibrating Fluidized Bed Dryer | PrincipleRaw material is fed into the dryer from the feeding end and moves forward continuously along with the vibration force. The hot air penetra... | |

| Continuous Production Fluidized Bed Dryer | DescriptionClean hot air enter fluid bed dryer through air distributor. The wet raw material fed from feeder forms the fluidizing state by hot air.... | |

| Batch Production Fluidized Bed Dryer | DescriptionUnder the negative working pressure by exhausting fan,Website:, fresh air will be firstly filtered during passing through air filter, an... | |

| Multilayer Mesh Belt Dryer | DescriptionDW Multi-layer belt dryer usually adopt two to five belt layers,Website:, raw material being fed from the top belt, and re-circulating l... | |

| Mesh Belt Dryer | ApplicationsDWF belt dryer is continuous-production drying equipment. The dryer being widely used for drying the piece,Website:, strip and particle... | |

| GMP Tray Dryer | Description1.The available heating resource for choice are steam,Website:, thermal oil, electricity, gas, oil2.Operation temperature ranges from 40... | |

| Tray Dryer | DescriptionThe CT-C Tray dryer support to use steam,Website:, electric, gas or oil as heating resource . The laminar air flow passes through the dr... | |

| Sludge Double Shaft Paddle Dryer | DescriptionSludge double shaft paddle dryer is a kind of indirect heated dryer. There is jacket on the body,Website:, hollow paddle strongly welded... | |

| Fluidized Bed Coater | PrincipleFluid-bed coater is a new style coating equipment that combined fluid-bed spraying technology and coating technology. It is widely used fo... | |

| Pharmaceutical Dry Granulator | DescriptionGZX model dry granulator is developed with combination of Germany technique. Compared against conventional dry granulator,Website:, GZX ... | |

| Rotary Drum Dryer | PrincipleGT model rotary drum dryer is a kind of indirect heating dryer in continuous production. Raw material fed from top or bottom of drum and s... | |

| Double Shaft Paddle Dryer | PrincipleKJG double paddle dryer is a kind of indirect heated dryer. There is jacket on the body of dryer,Website:, hollow paddle strongly welded o... | |

| Hot Plate Dryer | PrincipleWet raw materials are fed continuously on the first hot plate on the top of dryer. Raw materials then will be turned and agitated under th... | |

| Vacuum Hot Plate Dryer | DescriptionRaw material was agitated inside the dryer under vacuum condition. Evaporated moisture was sucked out by vacuum pump. Drying efficiency ... |