Taiyuan PLS Engineering & Technology CO.,Ltd

Контактная информация

Contact person:Yan Song

Tele:

Web:

TaiyuanPLS TechnologyDevelopment Co., Ltd. (hereinafter referred to as PLS TECH) is a joint-stock business backboned by high tech industry with a registered capital of RMB 12 million. The company’s management layer is mainly composed of the former technical and management backbones of Taiyuan Mining Machinery Group Co., Ltd. Our president also General Manager is a senior engineer who once was the director of the Design Institute of Taiyuan Mining Machinery Group Co.,Ltd and Deputy Chief Engineer of Taiyuan Mining Machinery Group Co., Ltd.

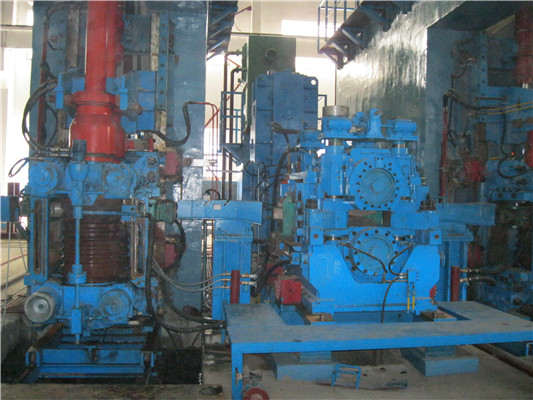

The company mainly engages in the research, design, development and manufacturing of metallurgicalequipment. It can not only undertake general contracting projects independently, but also design advanced electromechanical integration equipment for the users, and especially finish the complete automatic engineering in the whole metallurgical rolling field covering welded pipes, seamless steel pipes, rods, wire, plates, belts, etc.

Besides engineers (over 85% are senior engineers), the company also has strong research and new product development capacities, as well as whole sets of rolling equipment. Meanwhile, the company keeps long-term close partnerships with Taiyuan Mining Machinery Group Co., Ltd., and metallurgical design institute, metallurgical companies and metallurgical experts both at home and abroad.

Since its establishment, the company has always adhered to the concept of “Honesty, Study, Innovation, Cooperate,Practical,and Efficiency”, and made great efforts unremittingly to build its own brands and make it a new business with comprehensive research, design, development and manufacturing capacities.

With the continuous development of science and technology, the company actively explores in the new technology field and constantly absorbs and digests advanced technologies in the world. As of now, it has successively designed and manufactured pipes, wire, and rods for Jigang Group Co., Ltd., Kunming Iron and Steel Group Co., Ltd., Jiuquan Iron and Steel (Group) Co., Ltd., Haixin Iron and Steel Co., Ltd., Xining Iron and Steel Co., Ltd., Anshan Iron and Steel Group Corporation, Shaanxi Longman Iron Steel Group, Jiangsu Changqiang Iron and Steel Co., Ltd., Fujian Jianian Iron and Steel Co., Ltd., Shandong Taifeng, Shandong Xiwang Group, Shandong Qianneng, Jiangxi Xinyu, Sichuan Chuanwei, Fushun New Iron and Steel, Wuhan Iron and Steel Group Corp., Xinjiang Bayi Iron and Steel Co.,Ltd., etc. Many products are the most advanced in China.

Today’s PLS (POINT, LINE, and SURFACE), just follows the concept of “Technology First & Design First”, actively implements its talent development strategy and constantly develops towards the direction of specialization and modernization as it has decided at its inception.

“Innovation, Progress, Satisfactory Solutions, Quality Product”is what the company pursues always.

The company is mainlyengaged in study, design, development and manufacturing of metallurgical equipment, particularly in the metallurgicalindustry we can independently achieve the project of complete plants in the whole field of metallurgical rolling from wire and bar, seamless steel tube, welded pipe etc.

The key members are mainly from Taiyuan Mining Machinery Group Company Ltd. with teams of batch technological quality control and accurate professional equipment, adhering the Group 30 years’rich experience of design and manufacturing.

Manufacturing base named Rolling Equipment Company Ltd. which is belong to Taiyuan Mining Machinery Group and located in Shanxi Province.

Товары:

| Rebar Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Crank flying shear of Hot Rolling Mill Production Line | The crank mechanism of flying shear make the two shearing blade translational motion, in the shearing area the blade nearly perpendicular to the ro... | |

| 650 3-High Rolling Mill of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Hot Rolling Mill Stand of Hot Rolling Mill Machine Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Shifting Reversing Mill SRM of Hot Rolling Mill Machine Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Heating Furnace of Hot Rolling Mill Production Line | The matched heating furnace in our company is such a continuous system heating from billet to the rolling. According to differentiate of heat sourc... | |

| Fast Heating Induction Furnace of Hot Rolling Mill Production Line | The matched heating furnace in our company is such a continuous system heating from billet to the rolling. According to differentiate of heat sourc... | |

| Rebar of Hot Rolling Mill Machine Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| High Pressure Water Descaling of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| 300t Cold Pendulum Shear of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| 850 T Cold Shear of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| 450 T Cold Pendulum Shear of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Cold Shear of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| No. 1 Flying Shear of Hot Rolling Mill Production Line | Uses: head-cut and tail-cut , and chopped pieces in accident Cutting area : Max. diameter 12-70mm Cutting temperature: Min.650°c Max. cutting f... | |

| No. 2 Flying Shear of Hot Rolling Mill Production Line | Uses: head-cut and tail-cut , and chopped pieces in accident Cutting area : Max. diameter 12-70mm Cutting temperature: Min.650°c Max. cutting f... | |

| No. 3 Flying Shear of Hot Rolling Mill Production Line | Uses: head-cut and tail-cut , and chopped pieces in accident Cutting area : Max. diameter 12-70mm Cutting temperature: Min.650°c Max. cutting f... | |

| Crank Flying Shear of Hot Rolling Mill Production Line | Equipment features: 1. The crank mechanism of flying shear make the two shearing blade translational motion, in the shearing area the blade nearly ... | |

| Crank Rotary Flying Shear of Hot Rolling Mill Production Line | Uses: head-cut and tail-cut , and chopped pieces in accident Cutting area : Max. diameter 12-70mm Cutting temperature: Min.650°c Max. cutting f... | |

| Sizing Cold Shear of Hot Rolling Mill Production Line | Uses: head-cut and tail-cut , and chopped pieces in accident Cutting area : Max. diameter 12-70mm Cutting temperature: Min.650°c Max. cutting f... | |

| Pinch Roll of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Reducer of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... | |

| Bar Cooling Bed of Hot Rolling Mill Production Line | •Cooling bed of small bar is mainly based on POMINI type. Steel charged by apron board, bar stepping cooled by motor to drive eccentric wheel,... | |

| Chain-Type Cooling Bed of Hot Rolling Mill Production Line | •Cooling bed of small bar is mainly based on POMINI type. Steel charged by apron board, bar stepping cooled by motor to drive eccentric wheel,... | |

| Roller Cooling Bed of Hot Rolling Mill Production Line | •Cooling bed of small bar is mainly based on POMINI type. Steel charged by apron board, bar stepping cooled by motor to drive eccentric wheel,... | |

| Walking Beam Cooling Bed of Hot Rolling Mill Production Line | •Cooling bed of small bar is mainly based on POMINI type. Steel charged by apron board, bar stepping cooled by motor to drive eccentric wheel,... | |

| Horizontal Vertical Convertible Rolling Mill of Hot Rolling Mill Production Line | High speed wire rod rolling mill and finishing mill with rolling speed from 36m/s to 120m/s can turn billets with cross section areas of 150 x 150 ... |