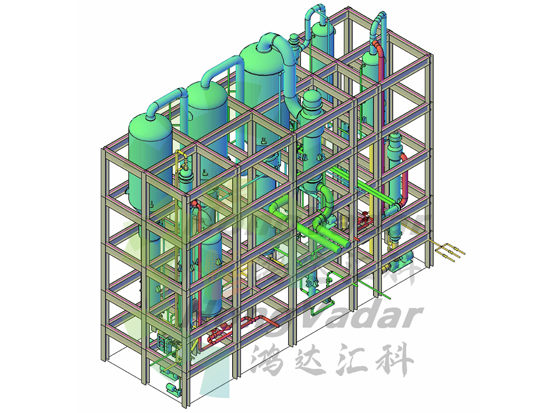

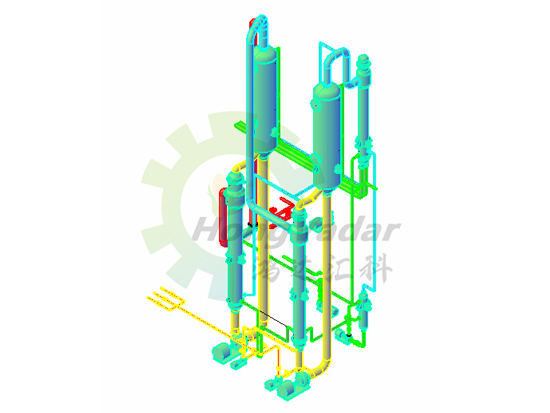

Continuous Evaporative Crystallization System

Hongvadar is advanced in many areas, such as being the corn starch production plant and small scale tomato processing plant.

HVD-CC-T series continuous crystallisation and evaporationsystem is designed and developed by our factory with patent applied.

Core Of Crystallization Process Control

Design enough long crystal time according to crystal characteristics to create an environment conducive to the growth of crystal structure.

Adjust the direction of materials, control the number of microcrystals, realize the whole process control of seed generation, seed growth, elimination of microcrystals, growth of qualified particles, and timely discharge of qualified particles.

Most businesses take crystallization as the process of concentration. It is believed that the concentration reaches supersaturation, the crystal forms naturally, and there is no awareness and measures to control the crystal quality. The control of the crystal purpose is ignored, and the influence of crystallization on separation and drying is not fully considered, which makes the subsequent section treatment more difficult due to the crystallization. Therefore, the purpose of crystallization is to improve the overall yield and product quality and reduce the product production cost.

Characteristics Of Evaporative Crystallization System

Crystallisation and evaporation system/evaporation vs crystallizationsystemis used for products with general requirements on crystal shape and size and can achieve high concentration discharging.

According to the characteristics of materials and the evaporation capacity, continuous crystallisationand evaporation system can be designed as a single-effect or multi-effect evaporative crystallization system.

The unique design of the continuous oscillatory baffled crystallizer, circulating liquid evaporator crystallizerand continuous cooling crystallizercan meet the intermittent crystallization, semi-continuous crystallization, and continuous crystallization system. It can meet the continuous feed, continuous discharge process requirements.

The whole crystallisation and evaporation process system evaporates under the vacuum condition, with relatively low temp, fast evaporation crystallisationspeed, high evaporation concentration, and the relatively high viscosity of the liquid material is not easy to scale or block, which can achieve the maximum crystal ratio under the same energy consumption.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy saving equipment system for the customer. The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose Chinese GB, International ISO, American standard ASME, European standard PED and other standards for equipment design and production according to their needs.

Continuous Evaporative Crystallization System Technical Parameter

|

Model |

Ev capacitykg/h |

Steam consumption kg/h |

Each effect vacuum, mmHg |

Each effect temp. ℃ |

Steam pres.MPa |

Feed DS,% |

Discharge DS, % |

||||

|

1steffect |

2ndeffect |

3rdeffect |

1steffect |

2ndeffect |

3rdeffect |

||||||

|

HVD-CC1.0-T |

330-400 |

300 |

510 |

750 |

85 |

55 |

5-6(MSG) |

55-65(MSG) |

|||

|

HVD-CC3.0-T |

990-1200 |

||||||||||

|

HVD-CC4.5-T |

1485-1800 |

||||||||||

|

HVD-CC6.0-T |

1980-2400 |

||||||||||

|

HVD-CC9.0-T |

2970-3600 |

||||||||||

|

HVD-CC12.0-T |

3960-4800 |

||||||||||

|

HVD-CC15.0-T |

4950-6000 |

||||||||||

|

HVD-CC20.0-T |

6600-8000 |

||||||||||

If you want to know how is crystallization different from evaporation, you can click our official website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Desand Cyclone and Germ Cyclone | Desand Cyclone HVD-CY-DS series desand cyclone is mainly used in starch production to remove sediment, metal particles, and other impurities in st... | |

| Evaporator System | HongVadar has all kinds of engineering and technical personnel with more than 30 people, including 8 senior designers, who had serviced for the int... | |

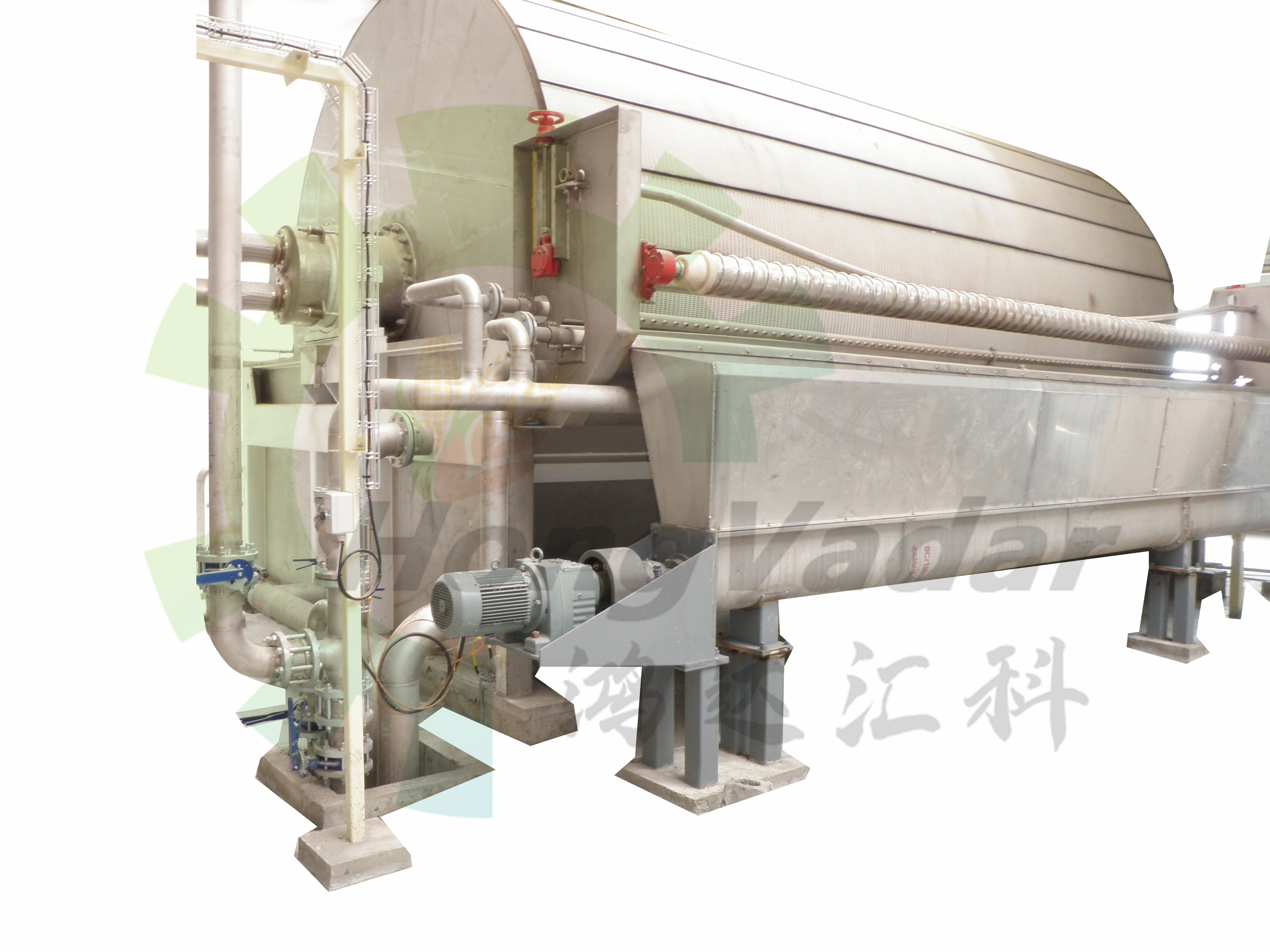

| Rotary Vacuum Filter | Pre-coating Vacuum Filter System HVD-PVF-P series pre-coating vacuum filter works on the same principle as the general rotary vacuum filter in sug... | |

| Full Automatic Intelligent Ion Exchange System | HVD-AIE-Q automatic intelligent ion exchange filtration system, using valve array control, desalting (decoloring), regeneration, washing at the sam... | |

| Continuous Evaporative Crystallization System | HVD-CC-T series continuous crystallization equipmentsystem is designed and developed by our factory with patent applied. Core Of Evaporative Cry... |

Похожие товары

| Scaffold Sleeve Coupler | Продавец: SHIJIAZHUANG LANGHENG COMMERCE&TRADING CO., LTD | Scaffold Sleeve Coupler Scaffold Sleeve Couplersare known by various names depending on region o... | |

| Optical Brightener OB | Продавец: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Optical Brightener OB Optical brightener OB is poorly soluble in water, and soluble in alkane, m... | |

| Solvent Blue 36 | Продавец: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Solvent Blue 36 Solvent Blue 36is an industrial colorant with excellent tinting power and transp... | |

| Fast Scarlet G Base | Продавец: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Fast Scarlet G Base Basic informationof Fast Scarlet G Base: Product name: Fast Scarlet G Base ... | |

| Sulphur Black BR 200% | Продавец: TIANJIN LEADING IMPORT & EXPORT CO., LTD | Sulphur Black BR 200% Product Name:Sulphur Black BR 200% :Sulphur Black 1 CAS No.:1326-82-... |