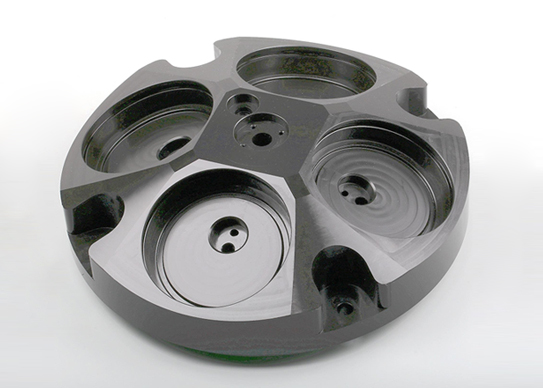

BLACKENING COATING

Put the metal parts into the solution of NaOH, NaNO2 and other potions. At a certain temperature, the parts will react chemically to produce a thin blue (black) oxide film. Blackening can be divided into normal temperature blackening and high temperature blackening. Generally, the surface oxide film of normal temperature blackening is relatively thin, and the effect of secondary blackening is better. Theblackening treatmenttemperature at high temperature is about 135 ° to 155 ° and the blackening effect is also the best.

What Is Blackening For Metal?

Metal blackening is a common CNC surface finishtreatment process. The purpose of blackening is to prevent rust on the metal surface. There are two kinds of metal blackening: alkaline heating blackening and normal temperature blackening. The problem of checking the antirust effect may occur due to process problems in normal temperature blackening.

How Do You Blacken Metal?

The process flow of metal blackening is as follows:

Degreasing: Boil the parts in degreasing solution for 20~30 minutes at 80~100 ℃.

Cold water cleaning: rinse with flowing clean water.

Pickling: wash with hydrochloric acid solution at room temperature for no more than 30 seconds.

Blackening (put the blackening liquid in a stainless-steel container and heat the bottom with an electric furnace)

Water washing: wash with flowing cold water or warm water for 30-60 seconds.

Boiling water cleaning: 2-5 minutes.

Saponification treatment: temperature 80~90°, time 2-3 minutes.

Immerse in oil: immerse in transformer oil or spindle oil at about 80° for 1-3 minutes, and then the finished product is cleaned.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| POWDER COATING | POWDER COATING The atomized paint is sprayed on the metal surface and solidified after high-temperature baking to form the effects of anti-corrosi... | |

| ELECTRONICS CNC MACHINING | ELECTRONICS CNC MACHINING Our purpose is to provide customers with processing services of various testing fixtures, mold parts and non-calibrated ... | |

| POLISHING | POLISHING Polishing is divided into precision polishing and decorative polishing. Improve precision polishing: generally, when the dimensional acc... | |

| CNC PLASTIC MACHINING | The characteristics of plastic cnc machining chinamaterial are defined by the melting point temperature (150 ° to 450 °) and the use enviro... | |

| BLACKENING COATING | Put the metal parts into the solution of NaOH, NaNO2 and other potions. At a certain temperature, the parts will react chemically to produce a thin... |

Похожие товары

| LDC-350B Automatic Label Die Cutting Machine | Продавец: RUIAN LOYAL MACHINERY CO.,LTD | LDC-350B Automatic Label Die Cutting Machine This die cutting machine is ideal for electronic pr... | |

| LY-RS320 Semi-Rotary Die Cutting Machine | Продавец: RUIAN LOYAL MACHINERY CO.,LTD | LY-RS320 SemiRotary Die Cutting Machine This label press machine is the most ideal machine for p... | |

| Flexo Printing Machine | Продавец: RUIAN LOYAL MACHINERY CO.,LTD | In the 1980s, flexographic printing technology developed rapidly. The performance of flexographic... | |

| LYS-S1300/1600 High speed flexible packing film slitting machine | Продавец: RUIAN LOYAL MACHINERY CO.,LTD | LYS-S1300/1600 High speed flexible packing film slitting machine This kind slitting machine is a... | |

| Die Cutting Machine | Продавец: RUIAN LOYAL MACHINERY CO.,LTD | The adhesive label rotary die cutting machineis all kinds of trademarks processed into the final ... |