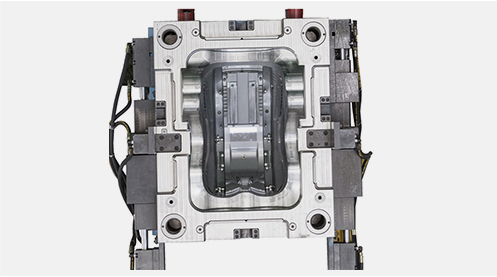

Family Mould

What is the family mold?

A mold that can only produce one product at a time is called a single-cavity injection mold. If a mould is used to produce two or more plastic parts at a time, multi-cavity injection, if the parts are different, such a mold is called family mold.

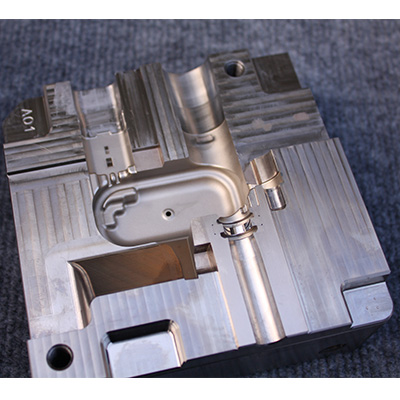

The plastic parts produced by the single cavity mold have high precision, easy control of process parameters, simple mold structure, low mold manufacturing cost and short cycle time. However, the productivity of plastic molding is low, and the cost of plastic parts is high, which is suitable for large plastic parts, high precision requirements or small batches and trial production.

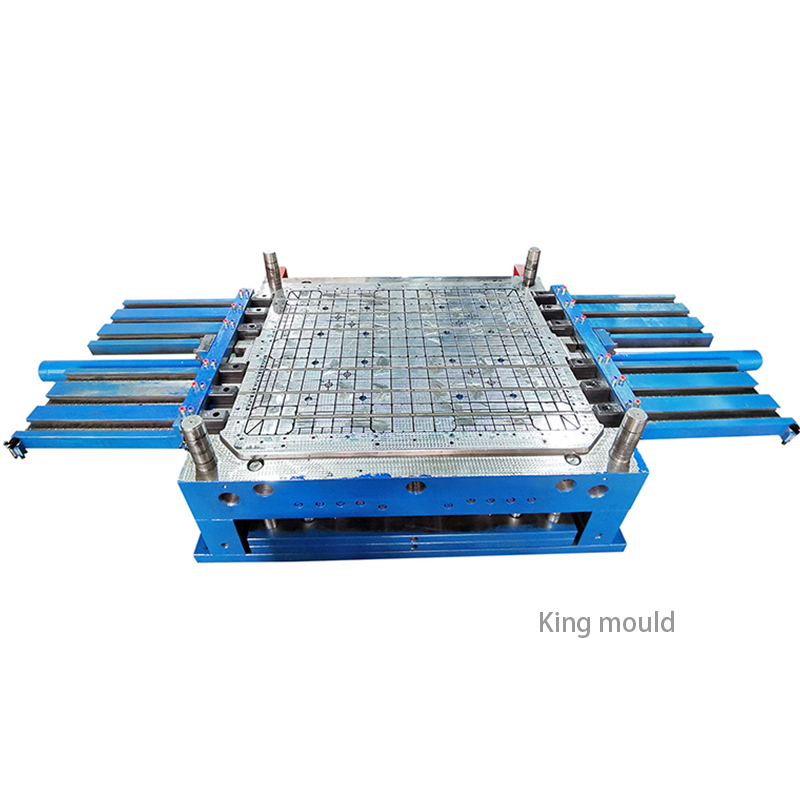

The plastic parts produced by the multi-cavity mold or family mold have low precision, it is difficult to control the process parameters, the mold structure is relatively complicated, the mold cost is high, and the cycle time is longer. However, productivity is higher, the cost of plastic parts is lower, and it is suitable for large quantities and long-term production of small-sized plastic parts.

The number of cavities is often determined by factors such as budget, clamping force, plastic part structure, and injection volume.

When designing a multi-cavity mold, one method is to determine the model of the injection molding machine, and then calculate the number of cavities according to the technical parameters of the injection molding machine and the technical requirements of the plastic parts; the other method is based on the requirements for production efficiency and the structure of the part require the number of cavities to be determined, and then choose the proper injection molding machine or check the existing injection molding machine.

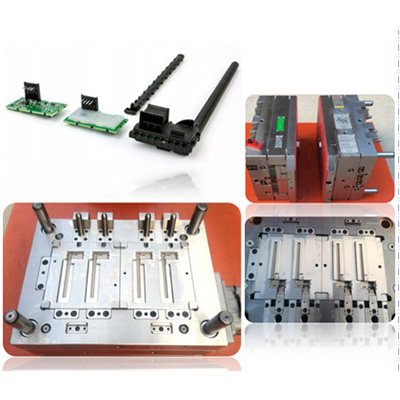

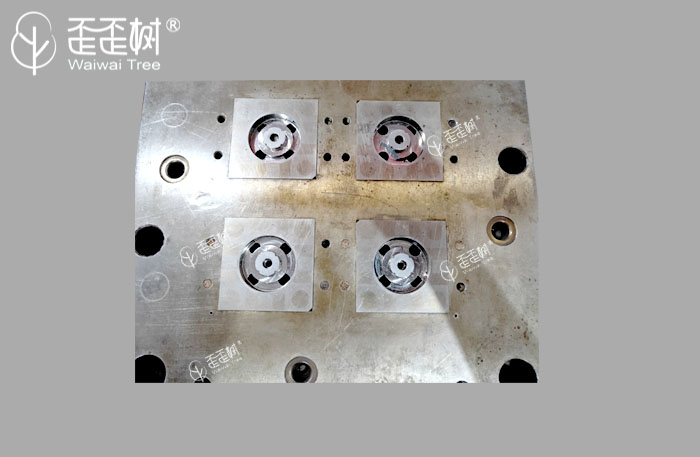

We normally make the multi-cavity mold with 2 cavities, 4 cavities, 8 cavities, 16 cavities, 32 cavities, 48 cavities, etc. For family mold, we normally make at 1+1 cavities, 2+2 cavities, 4+4 cavities, 8+8 cavities, we can find the numbers are always double. Family mold injection moldingis different plastic parts in the same mould, this solution saves tooling and molding cost. For most family mold, the plastic part is in same material & similar size, HanKing Mould will help customers to analyze the possibility to make the best economic plastic injection mould.

About Hanking Mould

HanKing Mould Enginering Ltd. started the business in the year of 1996 as a plastic molding china. With continuous developments and progresses, we have become a professional Chinese plastic injection tooling company, offering custom plastic injection molding service, plastic molding manufacturing and other mould making services.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Automotive Mold | Automotive Molds Professional Automotive Injection Mold for Cartridge Fuses TolerancesPlates and Mold Base Components:± 0.013 mm (± ... | |

| Automotive Mold | HanKing Mould technologyof shenzhen hanking for globally Automotive & Vehicle products customers, more than 10 years of experience enabling the... | |

| Precision Automotive Parts | Mould Name: Precision Automotive PlasticsMould Part Material: PA66 G30 Product Description: BODY plastic Mould Cavity: Cavities Mold Mo... | |

| Insert Molding | What is insert molding? Insert molding refers to a molding process in which an integrated product is made by inserting a pre-prepared metal materi... | |

| Настройка ABS пластмасс | Китайская фабрика по производству пластиковых литьев Модель Hankin имеет ряд современных устройств, в том числе станок с ЧПУ Fanaco, электроискр... |

Похожие товары

| Plastic Injection Lightweight Pallet Mould | Продавец: Zhejiang Huaqi Information Technology Co., LTD | Discover the Pallet Mould, a game-changer in the world of logistics and material handling. Our Pa... | |

| Flange Molding | Продавец: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | Flange Molding Flanged joint is the main connection method in pipeline construction. Compared to... | |

| Производство литьевых форм | Продавец: HANKING MOULD ENGINEERING LTD. | HanKing Mould имеет такие преимущества, как низкие затраты на рабочую силу, короткое время изгото... | |

| Car Seat Mould for Kids | Продавец: Green Vitality Industry Co., Limited | Child safety seats are seats specially designed to protect children from injury or death in a col... | |

| Industrial Plastic Injection Mold | Продавец: Green Vitality Industry Co., Limited | The injection molding part is replacing metal products in many fields of industrial applications ... |