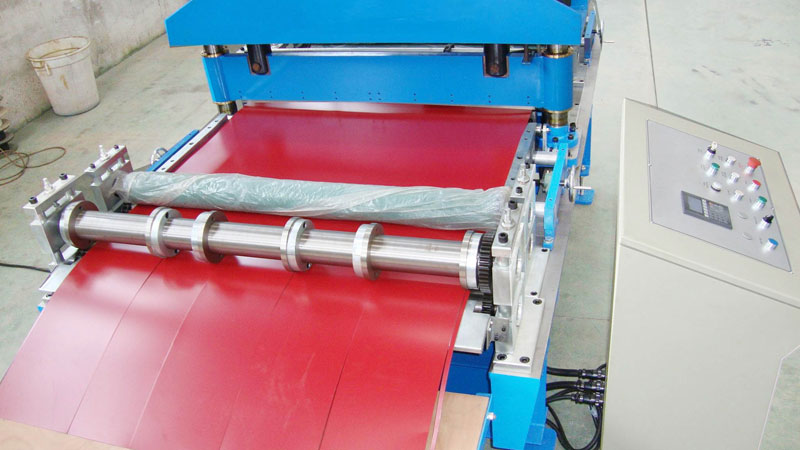

Cold Roll Forming Machine

The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is a plastic processing process to form a specific section profile.

Hangzhou Roll forming Trecinogy Co.,Ltd is a professional forming machine suppliersand exporter of all kinds of standard and nonstandard roll forming machinery. We offer various sheet metal and coil metal roll forming machines such as shelf and roll forming machines, downspout roll foming machines, double layer roll forming machines with the reliable process, high productivity, high reliability.

Our roll forming equipment consists of decolier machine, feeding table, guiding equipment, roll forming system, post-cutting system (electric o hydraulic), controlling system and hydraulic station. Wide variety of cold-formed steel, from the sub-section shape, with open, semi-closed and closed, the main products of roll forming machine are cold-formed channel steel, angle steel, Z section steel, cold-formed corrugated steel, pipe, square tube, rectangular tube, welded tube-shaped, rolling shutter doors and so on. Steel cross-section shape can be designed: size, accuracy, and length can flexibly be adjusted according to need, all supplied by length or double length, improve maternal utilization. Production processes can also be matched with the punch, so as to meet different requirements.

Characteristics of Cold Roll Forming Machine & Equipment

Reliable Process

Cold roll forming is a material saving, energy saving, efficient metal sheet forming process, new technology. Using this technology, not only can the cold roll forming equipment produce high-quality steel products, and can shorten the product development cycle, improve production efficiency, so as to improve the market competitiveness of enterprises.

High Productivity

The roll forming production lineonly needs 2-3 people to operate, with simple operation and low labour intensity. The production speed of the production line can be up to 60m/min, and the production speed can be adjusted according to the demand.

High Reliability

The main components of hydraulic, pneumatic and electrical systems of the roll forming machine lineare all imported high-quality components with stable performance and high reliability.

The Application of Cold Roll Forming Machine & Equipment

The custom roll forming machine realizes the continuous operation on the basis of guaranteeing the strength of steel, satisfies the diverse requirements of different design sizes, improves the product quality, accelerates the processing speed, and greatly reduces the labor intensity, saves a large number of manpower and material resources, and obtains good economic and social benefits in practice.

Cold-formed steel is widely used in the construction industry all over the world. It is used as roof frame, purlin, truss, rigid frame, wall frame, keel, roof board, wallboard, floor, doors, and windows, as well as containers, pipes, cofferdams, steel sheet piles, breakwater, etc. In recent years, the reticulated shell, shelf, single-story, and multi-story houses made of cold-formed steel have developed rapidly. The finished sheets become very welcomed modern building material with better anti-press and anti-bending performance. Therefore, the application of the sheet roll forming machine made in chinabecomes widely.

The roll forming machines from Hangzhou Roll Forming Technology Co., Ltd consist of decoiler machine, feeding table, guiding equipment, roll forming system, post-cutting system (electric or hydraulic), controlling system, and hydraulic station. Wide variety of cold-formed steel, from the sub-section shape, with open, semi-closed, and closed, the main products are cold-formed channel steel, angle steel, Z section steel, cold-formed corrugated steel, pipe, square tube, rectangular tube, welded tube-shaped, rolling shutter doors and so on. Steel cross-section shape can be designed; Size, accuracy, and length can be flexibly adjusted according to need, all supplied by length or double length, improve material utilization. Production processes can also be matched with the punch, to meet different requirements.

Hangzhou Roll Forming Technology Co., Ltd is a professional forming machine manufacturer and exporter of all kinds of standard and non-standard roll forming machinery. Welcome both national and international customers to contact us for more information about our cold-formed steel machines.

Roll Forming Machine FAQs

What can your roll forming equipment make?

We design and manufacture roll forming machines for roof/wall panel, metal deck, CUZM purlin, window/door frame, roll shutter door, guide rail, PV suppoter, racks, cable tray, downspout, gutter, guardrail and so on. As a China roll forming machine factory, we can also design and manufacture roll forming machines according to customers' profile drawings.

Does your rollformers have after-sales service?

We provide 12 months free warranty and free technical support for the whole life of any machine.

What components does your cold roll forming machine include?

Normally our roll forming machines consist of decoiler, guiding device, roll forming device, post cutting device, output table, hydraulic system and electric controlling system. And leveling system, servo feeding system, punching system, automatic stacking system, safety fences are optional.

Do you accept custom roll forming machine?

We not only manufacture standard roll forming machines, but also design and manufacture machines according to the profile drawings or samples from our customers.

How long is the customized metal roll forming machine delivered?

It takes about 45 days to 60 days after we received down payments.

As a professional tube mill manufacturer, we provide roll forming equipment for sale, roll forming machineand etc. Contact us to know roll forming machine specificationor buy our roll forming equipment.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Guardrail Roll Forming Machine | The highway guardrail is the main form of the semi-steel guardrail. It is a continuous structure in which corrugated steel guardrails are spliced t... | |

| Single Side Hydraulic Decoiler | SINGLE SIDE HYDRAULIC DECOILER The regular hydraulic decoilermachine adopts a cantilever-type structure. It Includes a machine frame, cantilever... | |

| Roofing Tile/Glazed Tile Making Machine | Roofing Tile & Glazed Tile Making Machine is for continuously roll forming and pressing step tiles sheets. The step length of this glazed roof ... | |

| High Speed Double Deck Roll Forming Machine | Features and advantages of High Speed Double Deck Roll Forming Machine With 2 layers of guiding tables, roll forming and cutting to length systems... | |

| HORIZONTAL ACCUMULATOR | rolling accumulatorare divided into the horizontal accumulator and vertical accumulator. The vertical accumulator requires a high plant height due ... |

Похожие товары

| Wide-Mouth Mold | Продавец: Taizhou Qihong Mold Co., Ltd. | A Wide-Mouth Mold is a specialized mold used to produce containers with a wider opening, often fo... | |

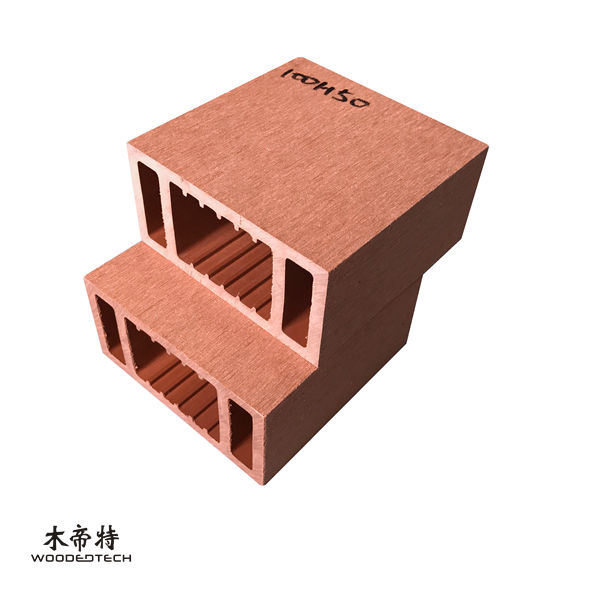

| Высококачественные наружные перила из деревопластикового композита (WPC) квадратной формы из Китая – прочное и стильное решение для ограждений | Продавец: Guangzhou woodedtech Co.,Ltd | Описание продукта: L10050 Квадратный поручень из древесно-пластикового композита (WPC) Преоб... | |

| Molybdenum Electrode | Продавец: Baoji City Changsheng Titanium Co.,Ltd | Molybdenum electrodemade by powder metallurgy technology with pure molybdenum powder has high mel... | |

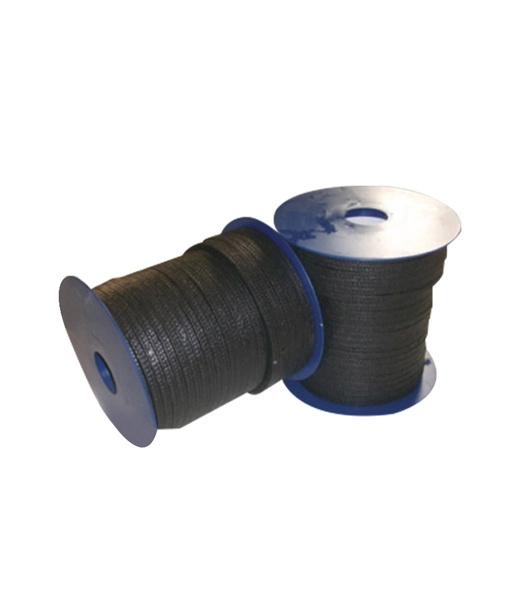

| PTFE Braided Packing | Продавец: Jiangsu Xinrui Plastic Technology Co.,Ltd | PTFE braided packingis a new type of sealing packing with desperse Teflon tape or tensile belt af... | |

| Molybdenum Boat | Продавец: Longhua Technology Group (Luoyang) Co., Ltd | Molybdenum boats are small, boat-shaped containers made of pure molybdenum or molybdenum alloys, ... |