METAL FLANGING

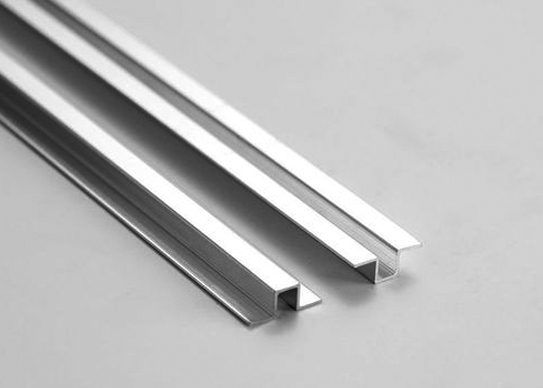

Flanging refers to the stamping process of turning the edge or outer edge of the hole on the workpiece into an upright straight edge with a die. It is included in the forming process of stamping.

WHAT IS THE ADVANTAGE OF METAL FLANGING?

It can process precision stamping parts with complex shape and good rigidity.

Improve the production efficiency. Save dies for some deep drawing parts. Reduce the manufacturing cost.

It can replace the deep drawing work of a complex shape workpiece, so flanging is especially suitable for small batch trial production.

Flanging is usually applied at the edge of the stamping part, which can effectively save the material.

WHAT SHOULD BE CONCERNED IN METAL FLAGGING?

Flanging is a stamping method that turns the workpiece with holes punched in advance into vertical flange along the hole edge. The deformation of hole flanging is from the tensile deformation of the material along the tangential direction, and the closer to the edges, the greater the deformation and the flanged area of workpiece gets thinner. Due to that, the hole edge may be cracked if not dealt properly. In order to prevent the cracking, the flanging degree of the inner hole of the workpiece must not be too large. If the flanging height is large, we can process flanging several times instead.

In flanging, the deformation degree is expressed by cofficient "K", which is the ratio of the aperture before flanging to the aperture after flanging. Obviously, the larger the value of K, the smaller the degree of deformation. On contrary, the smaller the value of K, the greater the degree of deformation, and more likely the edge of the flanging hole will be broken. The minimum value of K occurs with the maximum deformation degree which can be achieved without cracking the hole edge.

In order to prevent edge cracking, K shall not be too small and shall be greater than the minimum value introduced above. Experience shows that the minimum value of K is not only related to the type and performance of the material, but also to the relative thickness of the blank, and the shape of the product.

As a metalworking factory, we can offer sorts of metal work fabricationfor sale, if you are interested, please leave us a message.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

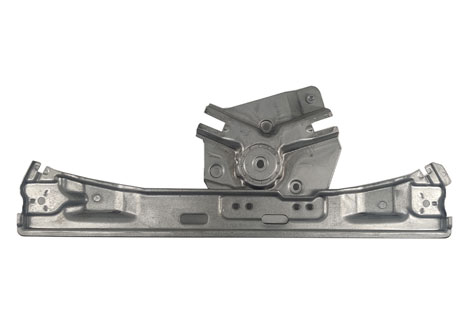

| AUTOMOTIVE PARTS | There are tremendous metal stamping parts you can find on a car. From a small clip to the entire body frame, the production of a car is always stro... | |

| STEERING ARM ADJUSTER IN LAWN MOWER ACTUATOR | Steering arm adjuster is set between drive arm and steering arm elbow, which is consisted of lower adjuster and upper adjuster. It belongs to drive... | |

| CAR EXHAUST PIPE | Car exhaust pipeis installed between the engine exhaust branch pipe and the muffler, making the whole exhaust system flexible. In this way, it c... | |

| AUTOMOTIVE PARTS | There are tremendous metal stamping parts you can find on a car. From a small clip to the entire body frame, the production of a car is always stro... | |

| METAL WELDING | Metal Welding Service Welding is a manufacturing process and technology to join metals or other thermoplastic materials such as plastics by heat... |

Похожие товары

| Steel Mesh Fence Panels | Продавец: 00000 | Steel Mesh Fence Panels Steel Mesh Fence Panels offer a durable, secure, and versatile fenc... | |

| automotive PVD coatings supplier | Продавец: 0000 | automotive PVD coatings supplier Automotive PVD Coatings Supplier When super-hard, low-fric... | |

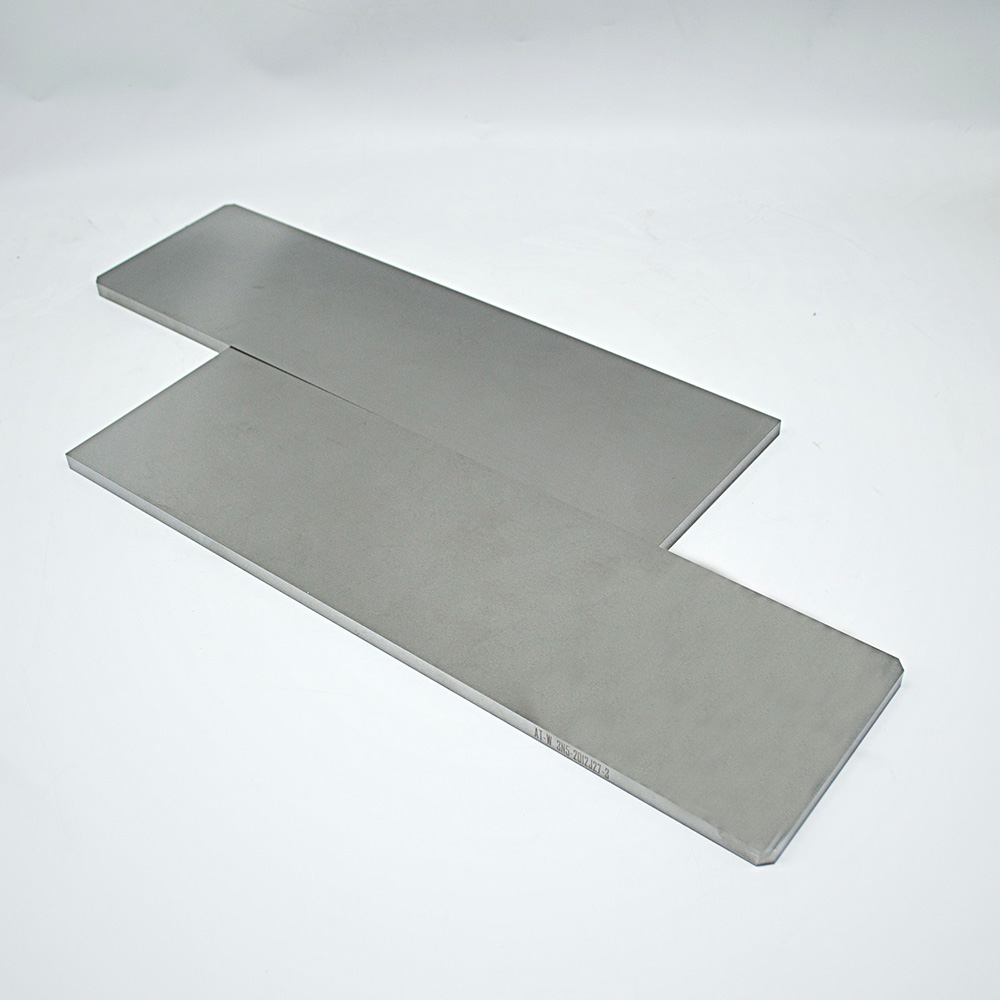

| Sputtering target for solar panels | Продавец: 0000 | Sputtering target for solar panels Sputtering Target for Solar Panels A thin-film solar cel... | |

| optical coating materials supplier | Продавец: 0000 | optical coating materials supplier Optical Coating Materials Supplier Advanced Targets is a... | |

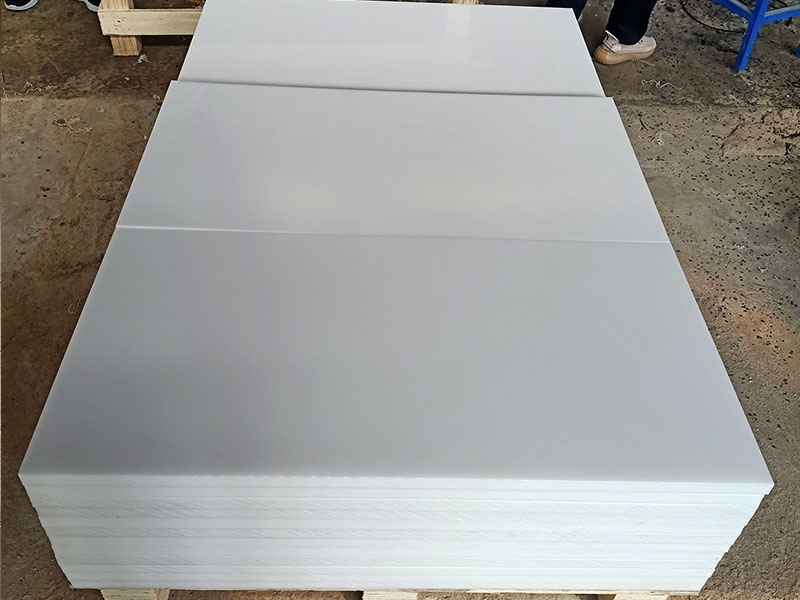

| UHMWPE Sheet supplier | Продавец: 00000 | UHMWPE Sheet supplier UHMWPE Sheet (ultra-high molecular weight polyethylene sheet) is a hi... |