Steel Pipe Shot Blasting Machine

Steel pipe shot blasting machineis a new type of special shot blasting equipment designed to user requirements, which is specially used for cleaning the outer wall of large circular steel pipes and wind power wind towers, and in some situations to clean inner and outer walls surfaces of shot blasting pipe.

Features of Steel Pipe Blasting Machine

Steel Pipe Shot Blasting Machine Structural Characteristics

Cleaning Sequence

Loading (user-supplied) → linkage line → enter shot blasting room → shot blasting (workpiece rotates while advancing) → feed out shot blasting room → linkage line → unloading (user-supplied)

Abrasive Circulation Sequence

Abrasive Storage → Flow Control → Shot Blasting Workpiece → Bucket Elevator Vertical Lift → Pellet Separation → (Recycling)

Structural characteristics

The structure of the machine consists of feeding roller table (12 meters), shot blasting machine, feeding roller table (12 meters), air control system, electric control system and dust removal system. The pipe shot blasting machine is composed of shot blasting chamber, shot blaster assembly, shot hopper and grille, shot slag separator, elevator, platform ladder railing, shot supply system and other components.

As the shot blasting companies, Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. It is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. Sand blasting Machines clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on.

Shot Blasting Room

Sand blasting room is primarily for cleaning big steel structural parts, vessel, truck chassis to remove the rusty spot, rusty layer and scale cinder on steel to obtain a uniform, smooth and glossy metal surface allowing improved coating quality and higher anti-corrosion performance. The shot blasting chamber is used in a wide variety of industries that require surface preparation prior to the application of a protective coating. The best sandblasting equipment clean or shape a surface using sand material known as abrasive which is propelled using high pressure typically through compressed air or blast wheel. So you can call it air blasting equipment or air powered sandblaster. Sand Blasting Machine are many types such as Sandblasting Cabinet, Container Blast Room, Automatic Sand Blasting Machines and so on. We have shot blasting room for sale, welcome to buy.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Tunnel Type Shot Blasting Machine | Tunnel type shot blasting machines also can be named hook pass-through type shot blaster. This type of cleaning machine is suitable for the surface... | |

| Shot Blasting Machine | As one of the professional shot blasting equipment manufacturers, BH offers a wide range of high-quality shot blasting machines to satisfy differen... | |

| Shot Blasting | Shot Blasting Machine Shot blasting machine is an effective way to do surface processing, including cleaning and roughening. We have a wide range ... | |

| QXY Steel Plate Pretreatment Line | QXY Steel Plate preservation lineis mainly used for surface treatment (namely preheating, rust removal, paint spraying and drying) of the steel pla... | |

| Steel Pipe Shot Blasting Machine | Shot blasting pipeshot blasting machine is a new type of special shot blasting equipment designed to user requirements, which is specially used for... |

Похожие товары

| AEMK 588 Loader | Продавец: AEMK MACHINE CO.,LTD | Высота кабины: 2670 мм Габаритные размеры (Д * Ш * В): 5700*2000*2670 мм Противовес передних коле... | |

| Quick Change Worktable | Продавец: Nextas Co.,Ltd | Quick Change Worktable Zero Point Pneumatic Chuck Zero Point Positioning Datum System NE... | |

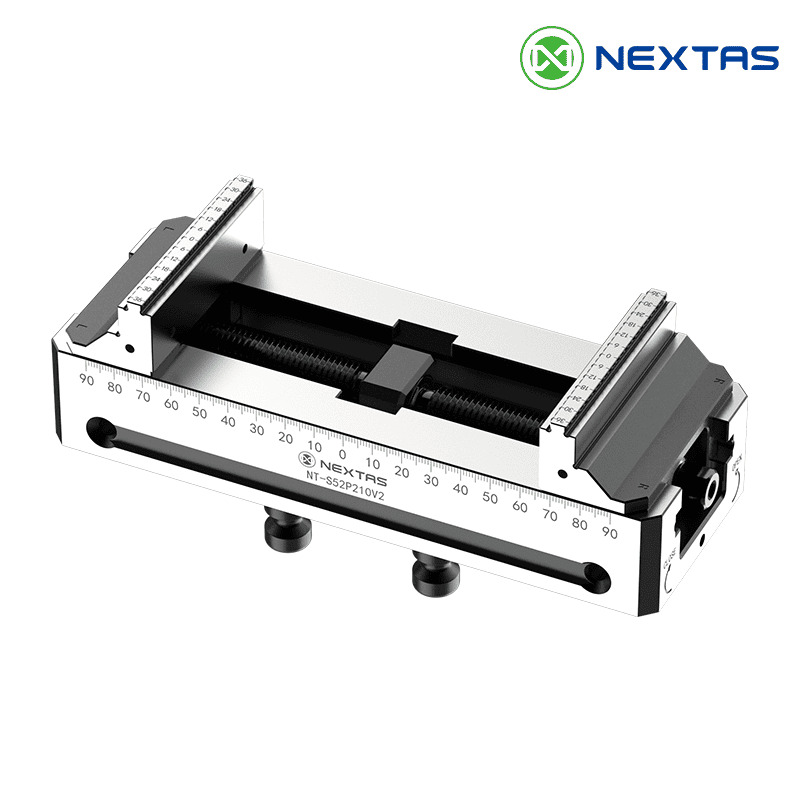

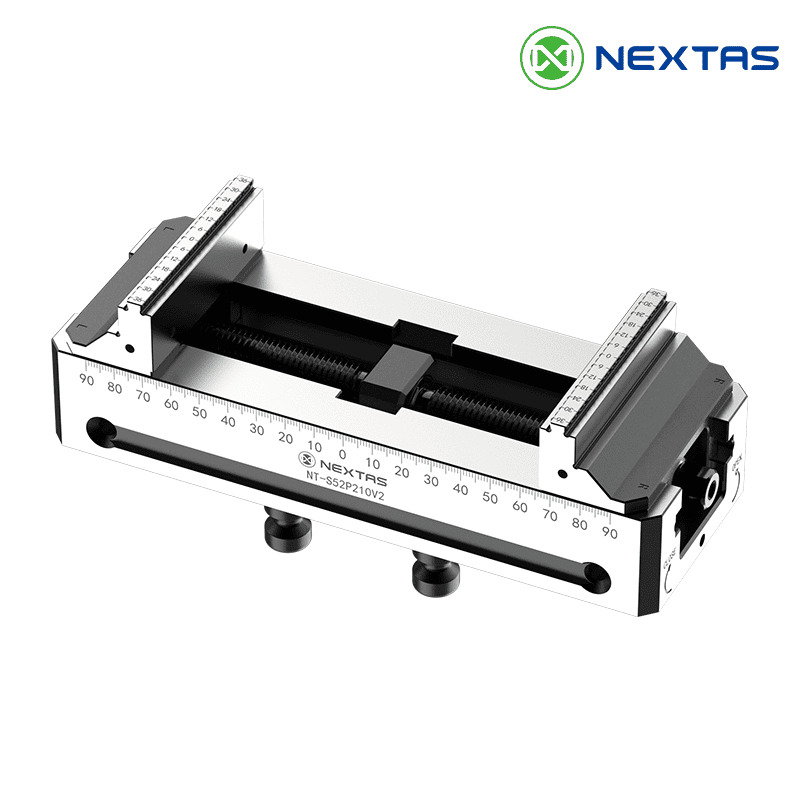

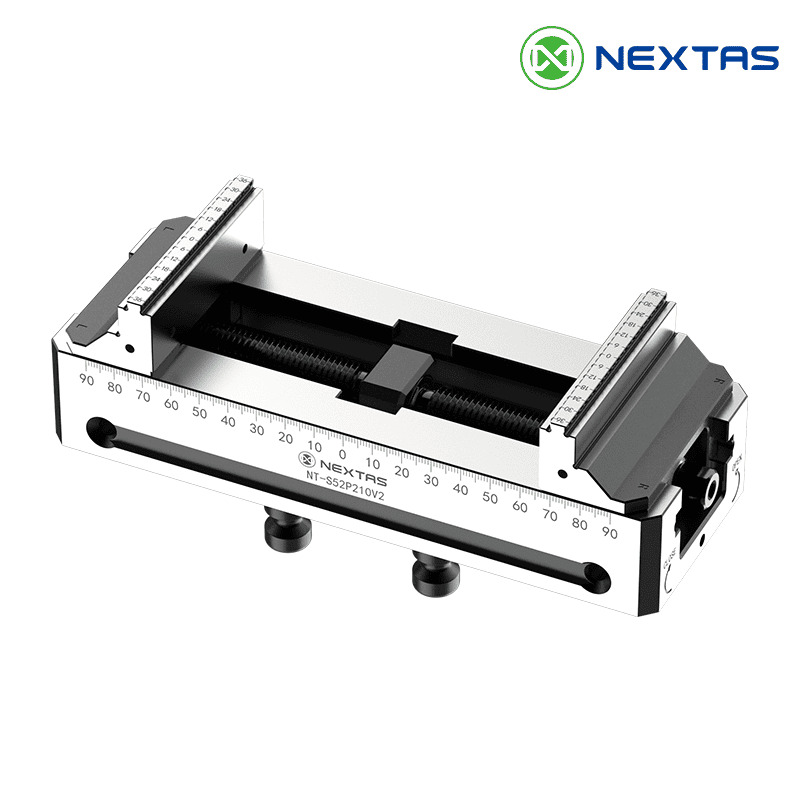

| Self Centering Vise | Продавец: Nextas Co.,Ltd | Self Centering Vise Key Advantages High precision: repeatability as tight as ≤ 0.005 mm ... | |

| BDS Positioning Chuck | Продавец: Nextas Co.,Ltd | BDS Positioning Chuck Self Centering Vise Self-centering vise is a type of workholding tool that... | |

| Quick Change Pallet System | Продавец: Nextas Co.,Ltd | Quick Change Pallet System Quick Change Pallet System Quick Change Pallet System delivers m... |