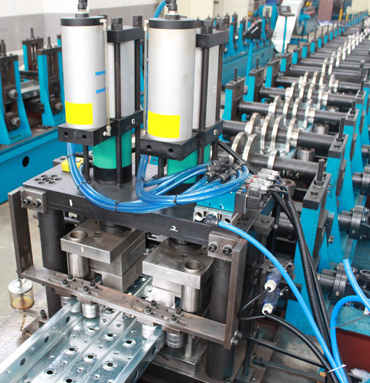

PANEL ROLL FORMING MACHINE

Overview of Panel Roll Forming Machine

The color plate produced by discharging, forming and post-forming cutting has a flat appearance, uniform paint, high strength and durability. Good metal deck roll forming machine is the key to good plate production. The colored steel plate enters the forming part of the roller table, and after molding, it is pressed into the pressed part, and is pressed into a section of equal distance, and the cutter is responsible for the fixed length cutting.

Widely used in industrial and civil buildings, such as factories, warehouses, stadiums, exhibition halls, theaters and other rooms and walls.

Design and Characteristics of panel forming machines

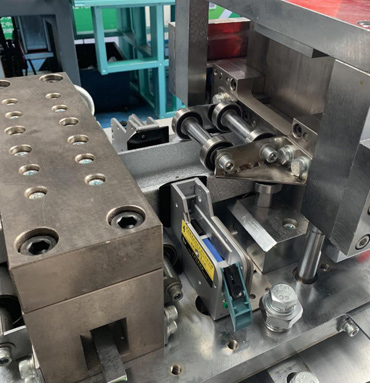

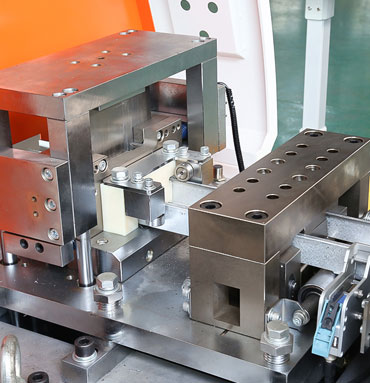

The arc part of the track is the core part of the slide rail. The arc position after the first few press forming, when the vertical pass is rolled up, the formed arc should be formed, and the effective tube bundle protection is carried out by the upper and lower rolls or the horizontal wheel. Otherwise, the arc position of the material will change during the stretching process, R becomes smaller and becomes a triangle, the steel ball is not in the end, the two points contact the sound, and when the R becomes large, the matching rail is swayed, and the track is blurred when used. Uneven force, deformation of the slide rail, shortening the life.

The average force principle of each pass, the average roller of the whole line is subjected to the average force, the wear is balanced, and the service life of the roll is extended.

For floor floor deck forming machine, the problem of rolling stability is often encountered in production. In fact, the single roller group is asymmetric, the left side is stressed, and the material is skewed to the right; the right side is strong, and the material is deflected to the left.

The C12MoV material adopts its wear resistance, but the specific strength and hardness are contradictory. When heat treatment, the red hardness of C12MoV should be utilized. After quenching, two or even three times of tempering can reach the hardness.

We have metal roll forming machines for sale, If you need panel forming machines, please contact us in time.

BOSJ estabilished in 2004, As a leading producer of many types of roll forming machine manufacturers in china, BOSJ has won worldwide reputation in this field. Our products have broad markets in Southeast Asia, India, North and South America,Western Asia, Russia and Australia. We guarantee first-rate after-sale service and product quality. Establishing abiding friendship with any customers interested in roll forming machines is our goal. Sincerely, we invite you to pay a visit to our company.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| ROLLING SHUTTER SLATS ROLL FORMING MACHINE | How to buy rolling shutter slats roll forming machine In the selection of materials should consider more lightweight, durable materials, so that e... | |

| PROFILE ROLL FORMING MACHINE | The steel profile roll forming machinemainly consists of four parts: The first is the input section - in this section, the material is loaded at a... | |

| SHEET ROLL FORMING MACHINE | BOSJ steelsheetrollformingmachinehave a reasonable design structure, beautiful appearance, convenient operation, adjustment and maintenance. The fu... | |

| Light Gauge Steel Framing C Purlin Roll Forming Machine | BOSJ estabilished in 2004, As one of theleading roll forming machine manufacturers in china,BOSJ has won worldwide reputation in this field. Our pr... | |

| ALUMINIUM ROLL FORMING MACHINE | How to Prevent Rust Treatment of Aluminum Profile Cold Forming Machine The gear oil used in the machine tool of the aluminum profile cold forming ... |

Похожие товары

| Cable Pulling Sock | Продавец: 00000 | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | Продавец: 00000 | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | Продавец: 00000 | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | Продавец: 00000 | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | Продавец: 00000 | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |