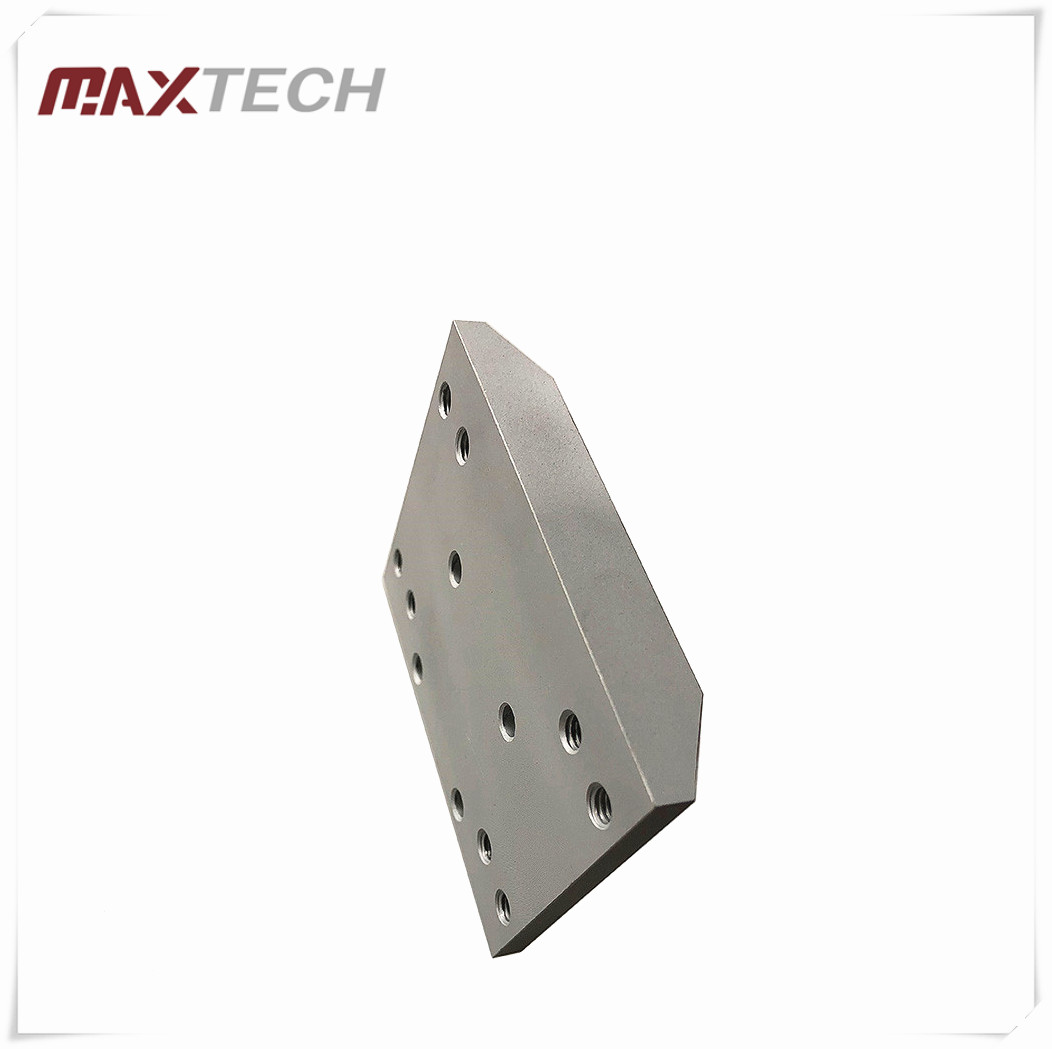

CNC processing anodized aluminum alloy parts

The CNC processing anodizing aluminum alloy parts are commonly used for a wide range of applications, producing parts that you’ll regularly find in aircrafts, consumer goods, sporting equipment and electronics, just to name a few.The anodizing aluminum process will help metal parts last longer than raw parts. The coating is much thinner than paints and powders, while still supplying a much harder surface as well. Another benefit of anodizing aluminum parts is that it offers an environmentally-friendly finish, making it easily recyclable. Pls contact us !

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| 146 Roll Forming Machine for ridge cap | Main Technical Parameter1 Suitable material Type Colored coating steelThickness (mm) 0.55Yield strength (Mpa) 345MpaWidth (mm) 4002 Forming Speed... | |

| Custom aluminum precision CNC machining parts | In modern industrial society,more and more aluminum precision parts can be machined by the CNC machining center.CNC Machining is a subtractive ma... | |

| 285 Ridge Cap Forming Machine | Technical Parameters1Suitable material Type Colored steel sheetThickness (mm) 0.5-0.55Yield Strength (Mpa) 230-300MpaWidth (mm) 418Wt of the Coil... | |

| CNC mechanical engineering parts milling machining | Our materials come from suppliers who share our commitment to quality.So using MAXTECH takes the guesswork out of CNC center machining milling se... | |

| Light Steel Keel Roll Forming Machine | Technical Parameters1 Suitable material Type Galvanized sheet plateThickness (mm) 0.85-1.6mmTensile strength (Mpa) 235-300MpaWidth (mm) Refer to ... |

Похожие товары

| Машина для производства канала строительства железнодорожных станций | Продавец: Superda Machine | Для производства высокоскоростной железнодорожной станции строительный материал. Ширина 126 мм к... | |

| Four-knife splitting machine | Продавец: Beijing REIT Technology Development Co., Ltd | Four-knife splitting machine This machine is a four-knife splitting machine with independent hyd... | |

| Insulation block benzene board insertion device | Продавец: Beijing REIT Technology Development Co., Ltd | Insulation block benzene board insertion device The thermal insulation block plug board device c... | |

| Light Steel Frame Machine produce C and U profile for light steel constructions | Продавец: DLY International Import and Export Ltd | Light steel frame machine was used for produce C and U profile for light steel constructions. Br... | |

| Low noise light steel frame light keel roll forming machine | Продавец: DLY International Import and Export Ltd | Product Description Light steel keel is a new type of building material. Light steel keel is wid... |