Process to Record Parameter of Sawdust Pellet Mill

By taking the biomass pellets to make the durability test, you can check the carbon content inside. Besides, you should check whether the feeding pipes of centrifugal collector and grading screen are blocked or not. All the above work should be carried out for every four hours.During this process, you should record the manufacturing parameters like production time, material temperature, durability, powered content, production variety, capacity in tons and efficiency, etc.

For the convenience to immediately find problems, deal failures and reduce loss, you should make the work of packaging coordinate together with the pelletizing work.Biomass particles, featured in the high thermal efficiency, easy storage and convenient transportation, can serve as the environmental-friendly fuel to take the places of fossil fuels like coal, oil and natural gas.

During the discharging process, you should immediately check the content of power and briquettes in biomass particles and temperature of biomass particles.When the low level indicator of pelleting bin presents the zero discharge, you should open thefeeding door of sawdust pellet machineand watch the flowing situation of material in feeding mouth.

If the flowing materials significantly reduces, you should open the cooler to increase the flowing amount.Then, you should notice the feeding-back pipe whether be blocked or not. If feeding-back pipe is blocked, you should stop the work of cooler. If feeding-back pipe is not blocked, you should watch the feeding situation at the feeding mouth.Interested in theprice of sawdust pellet mill? Leave messages on website to get the discounts that FTM China Machinery has prepared for you!

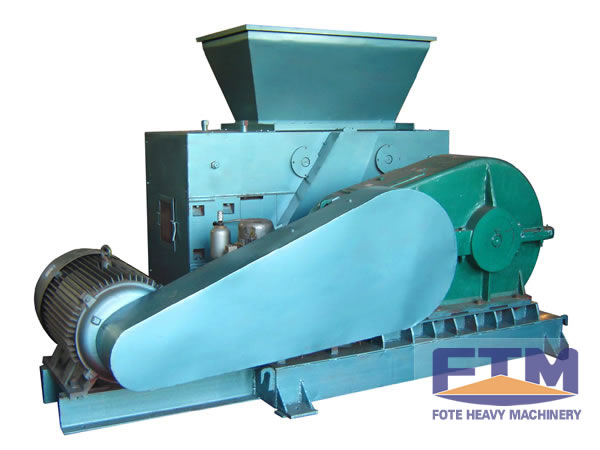

Fote Heavy Machinery:

Fote Official Email:

Отправить запрос, связаться с поставщиком

Другие товары поставщика

Все товары поставщика

Installation Details for the FTM Wood Pellet Mill

As its name implies, wood pellet mill is a machine used to suppress materials into wood pellets. The following content will discuss about the detai...

Ways to Improve Pellet Quality of Straw Pellet Mill

With the ability to turn agricultural and forestry wastes into biomass pellets of great value, straw pellet mill is becoming more and more popular ...

Усилия фоте сделать гидравлический Брикетировочный пресс

Гидравлические мяч пресс-машина, также названный как гидравлический брикет пресс-машина, отличная машина, с возможностью поворота отходов в вещи бо...

How to Run Fote Coal Briquette Plant at Normal?

If you are troubled with the wastes like powders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filing...

Мощное приложение из соломы Пелле Мельница в Китае

Для стран, богатых энергией биомассы, они могут мощно применить соломы гранулятор в сельских районах. Применение соломы машина лепешки может уменьш...

Похожие товары

HSC Paper Sheeting Machine

Продавец: Suzhou Paper Saw King Technology Co.,Ltd

HSC Paper Sheeting Machine

Product Description

HSC Paper Sheeting Machineincorporates an advanc...

Bottom Feed Slitting Rewinder

Продавец: Suzhou Paper Saw King Technology Co.,Ltd

Bottom Feed Slitting Rewinder

Product Description

The bottom feed slitting rewinderreceives pap...

HX Tape Laminating Slitting Rewinder

Продавец: Suzhou Paper Saw King Technology Co.,Ltd

HX Tape Laminating Slitting Rewinder

Product Description

The HX Tape Laminating Slitting Rewind...

Full Servo Band Saw Paper Slitter

Продавец: Suzhou Paper Saw King Technology Co.,Ltd

Full Servo Band Saw Paper Slitter

Product Description

The Full Servo Band Saw Paper Roll Slitte...

Z1500 Circular Saw Paper Roll Slitter

Продавец: Suzhou Paper Saw King Technology Co.,Ltd

Z1500 Circular Saw Paper Roll Slitter

Main Characteristics

Z1500 Circular Saw Paper Roll Slitte...