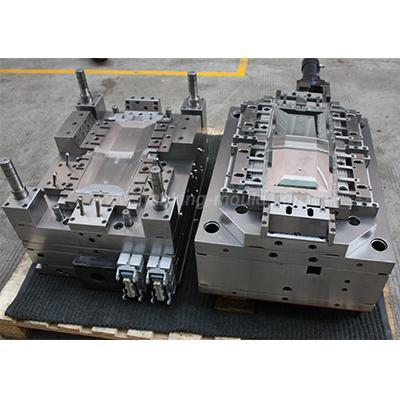

2K Mould

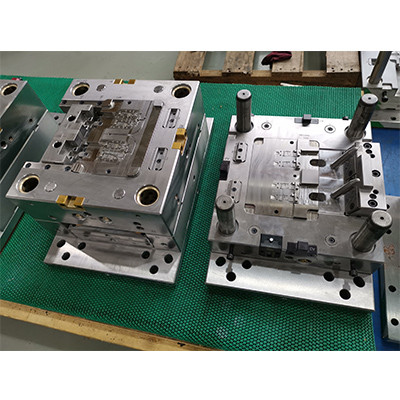

Unscrewing Mould

Mould Name: Unscrew Cap MouldPart Material:PP+TPEProduct Size: Product Description: Mould Cavity: Mould Size: 750*810*700mmSuitable Injection Machine:Mould Cavity Steel: Mould Injection System: Mold Master Hot...

More

Two Shot Mould

Two Shot Mould

Mould Name: Double Shot MouldPart Material:SAN+TPEProduct Size: 293*110.5*1.6 MMProduct Description: Water Tank Cover for a steamerMould Cavity: 1 CavityMould Size: 620*550*643 MMSuitable Injection Machine...

More

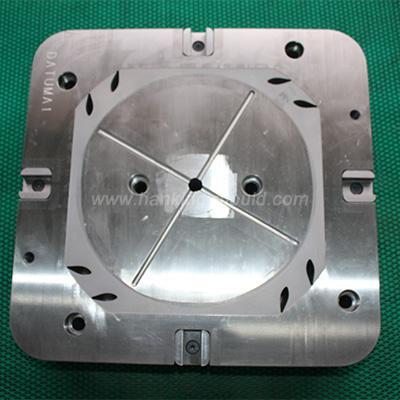

Two Component Toothbrush

Two Component Toothbrush

Plastic Injection Mould standard: DME, HASCO, Meusburger, China LKM Standard etc.Plastic Injection Mold Steel: ASSAB8407/P20/738/2083/2343ESR/NAK80/S136 etc.Mould Base: LKM Mould Base or others. Part...

More

Double Shot Mould

Double Shot Mould

Mould Name: Double Shot Mould,Part Material:SAN+TPE,Product Size: 293*110.5*1.6 MM,Product Description: Water Tank Cover for a steamer

More

Plastic Closure Mould

Plastic Closure Mould

As the two shot moulding ltd, HanKing Mould is an ISO9001:2015 certificated factory focusing on developing and manufacturing two shot plastic closure mould for house hold products.HanKing Capabilities: 1. Please Injection Mould...

More

The part molding by 2K Mouldhas been recognized by more and more people because it is superior to traditional injection-good structures and appearances. 2K or double shot mouldingconsists of processing two different polymers (or two different colors of one polymer) into an end product by means of one double shot injection molding process.

A two-color injection mould refers to 2k moulding processin which two different materials are injection molded into the same set of moulds to form an injection molded part from two materials. Some materials are of two different colors, some are soft and hard, and are molded by the same injection molding machine with two sets of injection mechanical equipment (two-color injection molding machine), and two kinds of plastics are injected in sequence.

After the mold is clamped, the first material is injected into the mold to form first plastic parts, and after the injection is completed, the mould is opened, the first product is left in the core side, and the template is rotated by 180 degrees, then the mould is closed again and the 2nd plastic resin is injected into the mould through the second barrel to form a two-color product.

What is the difference between a 2K mould and a normal mould?

The appearance of the product made by the two-color mould is more beautiful than that produced by the single-color mold, and it is easy to change the color without painting. The disadvantage is the high cost and high technical requirements.

The 2K injection molding is formed by mixing two materials, The two materials must have good bonding strength. In order to ensure good bonding strength, the bonding performance test must be carried out first, and the bonding performance is confirmed to be put into production.

The two cores of the 2K mould are the same, and the cavity is different.

The cavity and core of the double shot mould must be matched, which requires precise positioning of the mold base.

In the second injection molding of the two-color mold, in order to avoid the 2nd cavity scratching the first molded product, it is possible to design some clearance, but the strength of each sealing position must be carefully considered.

Two-color product application range:

Product function requirements, such as some light-transmitting buttons, power switch, remote control buttons, car switches, etc..

Improve the touch feel. Some hand-held products use soft rubber to feel comfortable, such as toothbrushes.

Increase the aesthetic appearance of the product, such as some two-color buttons and the logo of appearance parts, which are beautiful and will not be rubbed off.

The top and bottom covers of some electronic products, or the plastic cover with waterproof performance.

The nozzle of the 2k injection molding machine mainly has two parallel injection systems or is L-shaped.

Following the concept of customer first, hanking molddedicates to be a trustworthy tooling company by designing and manufacturing plastic injection molds, providing custom plastic molding manufacturing and services according to every individual's requirements. Hanking's successes are ensured by our management capability, technical knowledge, advanced plastic tooling equipment and professional injection molding services. We are pursuing better quality and technical capability to meet the demands of increasing mold making markets.

We are a responsible chinese injection molding manufacturersand mold maker company in China and have experience in supplying custom plastic injection molding service for many years. Our production sites have been accredited the certification of TS16949, ISO 14001 and ISO 9001, etc. You can fully trust our production sites, products and place your orders.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Insert Molding | What is insert molding? Insert molding refers to a molding process in which an integrated product is made by inserting a pre-prepared metal materi... | |

| Plastic Insert Mold | Plastic Insert Mold 139-86 Mould Name: Plastic Insert Mold Part Material: PA + Glassfiber Product Size: 11*30*1.3 Product Description: St... | |

| Industrial Mould | Industrial mould is not a mold technology process, but a type of mold that is distinguished from the purpose of use. Generally speaking, products ... | |

| Medical Molding Parts | Forehead thermometer plastic housing injection mold Plastic injection mold for customized forehead thermometer plastic housing and cover production... | |

| Medical Molding Parts | Injection Parts Medical HanKing has an experienced team focusing on making injection moulds and molded components for medical parts, medical instr... |

Похожие товары

| AIT500-SG High-Precision Current Sensor Transducer | Продавец: Shenzhen Hangzhi Precision Electronics Co., Ltd | Датчик AIT500-SG обладает высоким коэффициентом усиления и точностью измерений во всем диапазоне ... | |

| JWA2-M Oil Micro Moisture Sensor | Продавец: Shenzhen Joinwe Smart Co.,Ltd | JWA2-M micro moisture sensorcan quickly and accurately detect oil water activity (moisture satura... | |

| Made in China Displacement sensor 4000TDG for thermal power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Made in China Displacement sensor 4000TDG for thermal power plant YOYIK professional production ... | |

| China made Control System LVDT 5000TDGN for power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China made Control System LVDT 5000TDGN for power plant Dongfang Yoyik has advanced technology a... | |

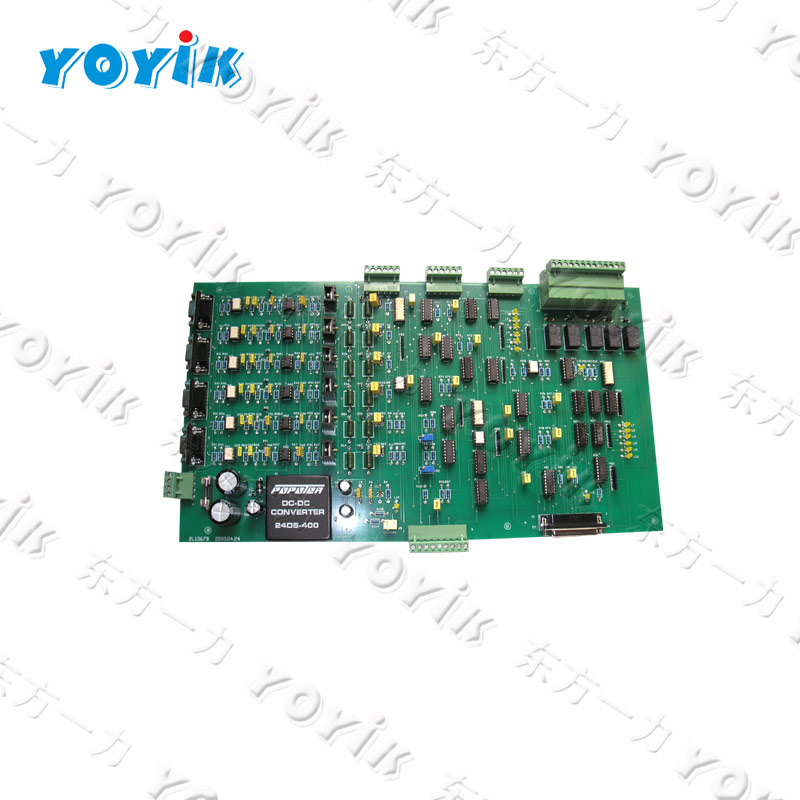

| China supplier main control board APF7.820.117A-A power plant spare parts | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China supplier main control board APF7.820.117A-A power plant spare parts Dongfang Yoyik is spec... |