Advantages and Differences of LED PCT

What is the difference between smd and cob led?

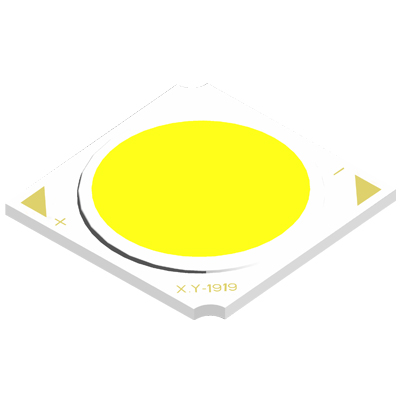

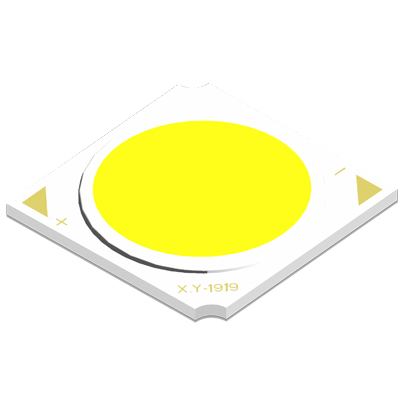

Definition of COB LED

COB LED chip is directly bonded and packaged on the whole substrate, i.e. numbers of chips are integrated together on the back board. It is mainly used to solve the problem of manufacturing high-power LED lamps with small-power chips. It can disperse the heat dissipation of the chips, improve the light efficiency and reduce the glare effect of LED lamps. COB has high luminous flux density, less glare and soft light, and emits a uniformly distributed light surface.

COB LED is a integrated surface LED technology with high light efficiency which is directly attached to a mirror metal substrate with a high rate of light reflection on an LED chip. This technology eliminates the concept of bracket, and has no plating, reflow soldering and no pasting process, thus reducing the process by nearly one third and saving the cost by one third.

COB LED can be simply understood as a high-power integrated surface LED, and the light emitting area and external dimension of the LED can be designed according to the external structure of the product.

Product features:

Electrical stability, circuit design, optical design and heat dissipation design are scientific and reasonable.

The heat sink technology is adopted to ensure that the LED has an industry-leading rate of heat flux maintenance ( 95 % ).

It is convenient for the secondary optical matching of the product and improves the lighting quality.

It has high color rendering, uniform lighting, no light spots. It is healthy and environmentally protective.

It is simple and convenient for installment and use. The difficulty of lamp design is reduced, and the cost of lamp processing and subsequent maintenance is saved.

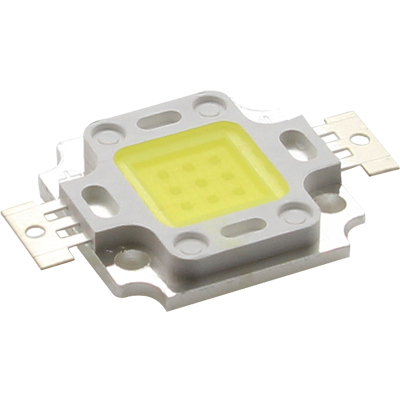

Definition of SMD LED(smd LED)

SMD LED means surface mounting LED. SMD patches can help improve production efficiency and are fit for different facility applications. It is a solid-state semiconductor device that can directly convert electricity into light. It has a voltage of 1.9-3.2V and the lowest red and yellow voltages. The heart of the LED is a semiconductor chip. One end of the chip is attached to a support. One end is a negative electrode, and the other end is connected to the positive electrode of the power supply, so that the whole chip is encapsulated by epoxy resin.

The semiconductor chip consists of two parts, one part is a P-type semiconductor in which holes predominate, and the other end is an N- type semiconductor in which electrons predominate. However, when the two semiconductors are connected, a P-N junction is formed between them.

When a current is applied to the chip through a wire, electrons are pushed to the p region where they recombine with holes and then emit energy in the form of photons, which is the principle of LED emission. The wavelength of light, that is, the color of light, is determined by the material forming the P-N junction.

COB LED vs SMD LED

Integrated LED is generally a different name for COB LED in the market, but in fact it cannot describe the characteristics of COB LED clearly. COB refers to Chip-On-Board, which directly encapsulates a small power chip on an aluminum substrate for fast heat dissipation, with a small chip area, high efficiency of heat dissipation and low driving current. Therefore, it has high heat dissipation with low thermal resistance and high thermal conductivity. Compared with ordinary SMD LED, it features higher brightness, lower thermal resistance ( 6℃/W ), lower light attenuation, higher apparent index, perfect light spot and long life.

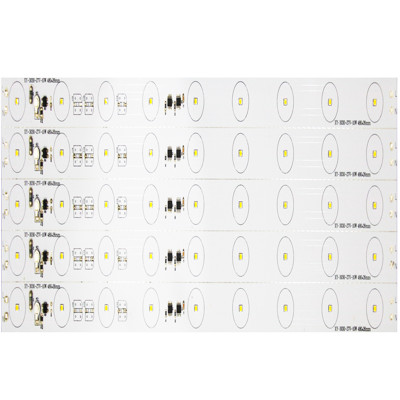

Low-power LEDs of SMD uniformly arranged on the aluminum substrate also known as integrated LED. In fact this integration is only soldering the SMD LED package ( finished LEDs ) on the aluminum substrate ( as shown in Figure 1 below ), instead of COB LEDs; COB directly packages the small power chip ( LED chip ) onto the aluminum substrate ( as shown in fig. 2 ). All COB LEDs are integrated LEDs, but not all integrated LEDs are COB.

The SMD LED is a single bead of patch LED lamp. COB LED is integrated with several SMD LED chips and packaged into a whole, which is smaller in size and higher in brightness than SMD LEDs with the same power.

PPA is an injection molding process; PCT materials have poor fluidity with troublesome operating process, so traditional stamping process is needed; EMC stents are produced by die top process. PPA and PCT are thermoplastic materials, while EMC is mainly made of epoxy resin and thermosetting materials. The temperature resistance of EMC LED is higher than that of PPA and PCT LED. The temperature resistance, yellowing and air tightness of PPA are lower than those of EMC and PCT, but the price of EMC has advantages. PPA, PCT and EMC can be enhanced because of the different heat dissipation. Due to different heat dissipation, PPA support can only achieve 0.1-0.2 W, PCT should be able to achieve 0.8 W at present. EMC bracket has the advantages of high heat resistance, yellowing resistance, high current, high power, high density, UV resistance and small size. At present, EMC bracket is favored by packaging factories. Many packaging enterprises have set up PCT production lines. PCT LED bracket is the development trend of later LED packaging.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| 6 Legs RGB High Power LED | Gold wire pure copper bracket packaging, mixed color effect, support surface mount technology. Full color RGB three in one led. Product Advantages... | |

| Flip COB LED | High light density flip chip cob led, this product USES no gold wire packaging, at the same time has the advantages of high central light intensity... | |

| 10W LED Wall Moudle | The Crescent - led packaging companiesDOB solution removes the inductors, electrolytic capacitors, transformers and other components, further reduc... | |

| Integrated COB LED | In order to meet customers' needs, our company provides 10-100w integrated white COB LED for option. For special customers requirements, we can pro... | |

| 3030 RGB SMD LED | SMD color consistency is good. The dispensing process adopts centrifugal technology to enhance the uniformity of the light spot and good heat dissi... |

Похожие товары

| LED Driving Light Manufacturer | Продавец: Foshan Xinruilai Lighting | LED Driving Light Manufacturer Led Driving / Off Road Light & Off-Road Light-It can p... | |

| LED Laser Light Manufacturer | Продавец: Foshan Xinruilai Lighting | LED Laser Light Manufacturer Laser Light LED Laser Light-Provides powerful lighting effec... | |

| iFixes iL37 Осветители для микроскопа Поляризованный кольцевой светильник 96 шт. Светодиодная лампа | Продавец: Шэньчжэнь Weike Repair Technology Co., Ltd. | Улучшите свою работу под микроскопом с помощью поляризованного кольцевого фонаря iFixes iL37 с 96... | |

| Energy Saving LED Tube Light | Продавец: D263, second floor, Hai Rong Hao Wan, Dalang south Road, Hualian Community, Long | Energy Saving LED Tube Light As a reliable led tube light company, led tube light factory, Anern ... | |

| Deep Cycle Opzv Tubular Gel Solar Battery | Продавец: D263, second floor, Hai Rong Hao Wan, Dalang south Road, Hualian Community, Long | Deep Cycle Opzv Tubular Gel Solar Battery The OPzV solar battery series is a tubular colloidal b... |