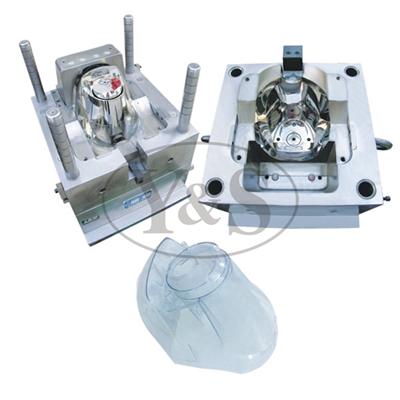

Cap Mould

Mould name:Cap Mould Shaping Mode:Injection MouldCap Mold,Website:, Cap Moulds, Cap Moulding, cap molding, Cap injection moldCap mold design steps1. Cap mold for the design feasibility analysis, computer chassis, for example, the first component of each product drawings use design software for analysis group legislature that we work in said sets of plans to ensure proper before the mold design drawings for each product sex, on the other hand can be familiar with the importance of each component in the entire chassis to determine the size of the focus, so that in the mold design is very good, specific sets of plans do not detail the methods herein described.2. Work cap mold after the analysis to be performed in, the product was analyzed what kind of mold structure and mold cap discharge step, each step to determine the content punch work, and expand the use of design software products, expand the product copy and then ships from the follow-up project to start forward, such as a requirement of five product process is completed at the time of stamping expand begin to four projects, three projects, two projects, a project from the drawings, and launched a graphic after expand the work carried out before a project, to complete five projects expand work and meticulous work, note that this step is very important, and need special care, which is good in one step, saving the drawing die in FIG. a lot of time for each project to determine the contents of the press after a good, including molding, the material thickness and outside the line of products retained to determine when the punch and die size for product expansion method will not be described here, will expand the specific method described.3. Preparation, preparation by Expand diagram, determine the size of the template in the drawing, including the fixed plate, stripper plate, punch, inserts, etc., pay attention to the product directly in the expanded view of preparation is carried out, so that the graph is very painting mold the big advantage, I have seen a lot of mold designers directly to expand FIG manual calculation preparation, this method is inefficient, draw a template size directly on the drawing to assemblage diagram form expression, a You can complete the preparation aspect, on the other hand save a lot of work in various parts of the mold work, because only join positioning pins, guide posts, screw holes can be drawn in the drawing in the preparation of the components work.4. After the completion of preparation can be drawn fully into the mold figure, drawing in the preparation of a reconstituted out drawing of each component, such as adding screw holes, guide post holes, positioning holes and other holes, and the punching die threading hole wire cutting various holes required in the mold, the gap between the upper and lower molding die, must not forget that it is after the completion of a product of mold Figure has almost completed 80%, while in the process of mold drawing graph should pay attention: each step of the production means, such as bench marking, cutting lines until a different processing step has a complete production well layer, so that the line cutting and drawing management have great benefits, such as color distinctions like size the label is also a very important work, but also one of the most troublesome work because a waste of time.5. After the above drawing is complete, in fact, we can not release drawings, the need for mold drawings proofing, all the accessories group sets up a different mold for each plate making different layers, and on the same basis as the guide pin hole until the mold Assembling analysis, and expanded view of each step product set into the group legislature figures, die gap and down to ensure that each template holes is consistent with the position and bend correctly.Main Technique ParametersCavity/CoreMaterial718H, P20, NAK80, 2316, 2738, 2344Product MaterialABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc.BaseLKM or by requestedStructureDouble color injection mould, Solid Mould, Insert Mould, Mould with Slide, Mould with LifterRunner SystemHot runner, Cold runnerCavitySingle cavity, multi cavities by requested (support similar products in one mould)FinishCorrosion word, Mirror finish, BrushedLongevityAvailable SHOTS will depend on the steel material you chooseMould standardHASCO, DME, MISUMI, or by requested etc.SoftwareCAD, Pro-E, UG, etcDesign Time3-7 days after we receive your samples or your drawingsMain TechniqueMilling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc.Production time1-3 months, depends on mould structurePackingWooden case, or by requestThe flow chart to place a mould orderReceive inquiries from customersWe will send you quotation within 24 hours after inquiries confirmedCustomers need to offer samples or 2D/3D drawings and some details about the mouldConfirm the order (quality , price , material , delivery time , payment terms etc.)According to your requirement to prepare the productionClients confirm the details of the mouldSurface shapingDrill holes , high speed carve machine ,wire cutting , EDM, etc.Arranging the test mould and sending the samples to customersIf customers do not satisfy the samples, please give us advice to repairRepair , Polish , TextureWe will send samples to customers for confirmingDelivery by sea or by air ,etcWHY CHOOSE US YUESEN MOULDBelow are just a few reasons to do business with yuesen:- Sufficient experience in plastic mold design and manufacture- Outstanding teamwork- Constant technical innovation- High-quality, low-cost, trouble-free molds- Attentive after-sales services

Другие товары поставщика

|

|

|

Mould name: lunch box mould Shaping Mode: Injection Mouldlunch box mold,Website:, Container Mould, Container MoldIn recent years, disposable foam l... |

|

|

|

Mould name:filter Mould Shaping Mode:Injection MouldPurifier Mold,Website:, Purifier Mould, filter Mold, filter Moulds, filter MoldingPurifier mold... |

|

|

|

Mould name:Cap Mould Shaping Mode:Injection MouldCap Mold,Website:, Cap Moulds, Cap Moulding, cap molding, Cap injection moldCap mold design steps1... |

|

|

|

Mould name:Oiler mould Shaping Mode:blow MouldOiler mold,Website:, Oiler molding, Machine oiler Mould, Machine oiler MoldBlow molding is in a high ... |

|

|

|

Mould name:Vacuum Cleaner Mould Shaping Mode:Injection MouldWith the improvement of people's living standards,Website:, ordinary household vacuum c... |

Все товары поставщика

Похожие товары

|

|

Working Clamp Lamp |

Продавец: ZHEJIANG TOPMB ELECTRICAL LIGHTING CO.,LTD |

TOPMBportable led work light with clamp, free up your desk space while providing you calm, bright... |

|

|

Ultra Wide Monitor Desk Lamp |

Продавец: ZHEJIANG TOPMB ELECTRICAL LIGHTING CO.,LTD |

TOPMB ultrawide led desk lampcan help you to lighting up your work area when you you have a doubl... |

|

|

Task Lamp |

Продавец: ZHEJIANG TOPMB ELECTRICAL LIGHTING CO.,LTD |

Magnifier lamp is a really essential tool for anyone who is engaged in precision assembly, inspec... |

|

|

Read Lamp |

Продавец: ZHEJIANG TOPMB ELECTRICAL LIGHTING CO.,LTD |

A great LED very bright reading lampsplays an important part in any desk work.TOPMB LED Eye Care ... |

|

|

Reading Desk Lamp |

Продавец: ZHEJIANG TOPMB ELECTRICAL LIGHTING CO.,LTD |

A wider, usb powered reading lampthat can protect your eyes when reading, there is a wide selecti... |