multi effect falling film evaporator / droping film evaporator

The series equipment of multi-effect adverse current evaporator, multi-effect arranged current evaporator, multi-effect film evaporator are suitable for evaporating concentration in

the industry of corn syrup, fermented sugar juice, juice, soft drink, milk, wine lees, pharmacy,

fermentation and high concentration organic or chemical wastewater. They have virtues of energy

saving, be heated quickly, suitable for the higher viscosity materials, high rate of concentration and it can also acquired the deionized water in good quality to satisfy industry boiler water requirement. They can unit into double-effect, triple-effect, four-effect and five-effect evaporation systems and also can design into waste heat evaporator which use top waste steam of restrain or disc dryer and other low heat value heat source as heat source. Thus, dose of primary steam decrease greatly, so it is easy to reach maximum save energy effect. When waste heat steam sufficient supply we can gain notable economic benefit without using primary steam completely.Operational principle:

Materials are uniformly distributed to every tube of the evaporator through the distributor, then the material turn into spirality film flow from the top to the bottom under the presence of gravity and the self evaporation secondary steam, at the same time, heat exchange occurring between material film and the steam of the tube plate, which made the water evaporation in the material. Also, steady temperature difference and heat-transfer area made stable water evaporation. The secondary steam that evaporated from the water can use several times, maximum heat energy utilization, steam consumption reduced greatly, all of which formed the design principle of multiple evaporation.Maximum performance feature:

The distribution panel of the evaporator adopts spirality, material distribution especially equalization,

the liquid turn into film decline along the tube intine absolutely, especially suitable for the concentrate of the sugar.

Head cover of the evaporator adopts flattop, which made them easy to clean and repair.

If the production output donot need large evaporation amount, heat-exchange area can be changed.

Vacuum system can be selected by operation method, such as liquid ring vacuum pump and water jet pump.

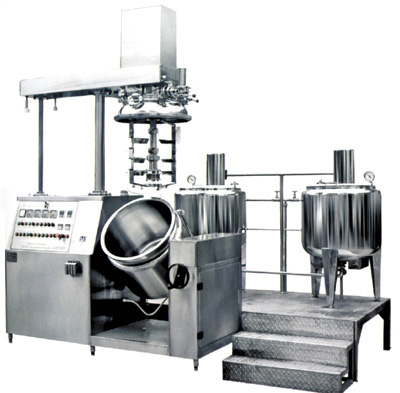

ALSO: forced circulation evaporator,falling film evaporator,multi effect forced circulating evaporator,waster water evaporator,waste water treatment system,chemical wastewater treating equipment,thermal recycling extracting units,multi effect concentrator,multi effect concentration equipment,alcohol recovery tower,alcohol recovery equipment,medical storage tank,chemical storage vessel,industry reactor tank,reacting vessel,agitator tank,mixing tank,mixing vessel,chemical mixer,horizontal storage tank,heat exchanger,heat exchanging equipment,HS type tubular oil cooler,oil cooling machine,emulsifier,vacuum emulsifier unit,crystallization evaporator,crystallization equipment,crystallization machine,thermal vapour recompression evaporator,TVR recompression evaporator,cosmetic cream production line,cosmetic cream equipment,medical cream producing machine,tomoto ketchup production line,tomoto ketchup making machine,tomoto sause making equipment,tomato paste production line,tomato paste equipment,tomato paste making machine,fruit joice production line,fruit joice producing machine,fruit joice making equipment,pharmacutical equipment,pharmacutical production line,pharmacutical machine,medicine production line,medicine extraction machine,alcohol recycling machine,food additive production line,starch sugar production line,concentrating equipment,concentration machine,concentration equipment,milk production line,milk concentration equipment,medicine extraction machine,pressure vessel,evaporation technology,concentration technology,alcohol recycling machine,alcohol recycling equipment,extraction equipment,crystallier technology,MVR evaporator,joice evaporator system,tomato paste processing machine,fruit joice concentrating production line,fruit joice producing equipment,orange joice production line,orange joice equipment,carrot joice producing machine,Tomato paste evaporator,tomato ketchup production line,tomato paste machine,tomato paste processing machine,tomato paste equipment,tomato paste production line,tomato sause equipment,fruit processing machine,fruit joice concentrating production line,beverage processing machine,lotion production line,lotion making machine,lotion equipment

Другие товары поставщика

Все товары поставщика

Похожие товары