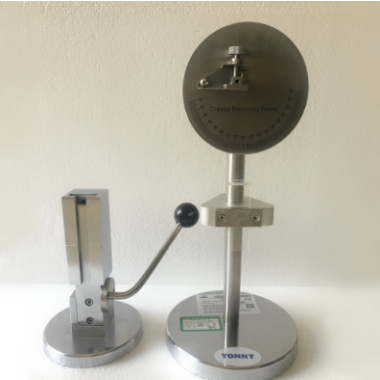

Roller Abrasion Tester

Car tire performance and its service life is directly related to the running condition of the car, and has a great impact on the safety driving of the car. Roller abrasion test apparatus is designed to simulate the wear state of the car tire material in the actual use condition, and suitable for the wear resistance test of materials under 160kg load. The device has an electric-driven controlled turntable, on which abrasive materials can be installed. The test roller is clamped by the test arm through the bearing. During the test, the actual use condition of material is simulated by adjusting the turntable speed, wear time, or test pressure, to identify the product quality and process results.

Structure & Function

The device is mainly composed of drive system, pressure system, heating system, and test arms.

Drive Unit:

Drive motor (about Φ 400mmx500mm,power 5.5kw)Programmable PLC can control the start of the motor, acceleration, deceleration, forward and reverse motion , deceleration and stop; The test base plate is driven to rotate by motor, and the abrasive material can be installed and fixed by screw nuts; End bearing mounted under the test base plate to improve the stability of the turntable operation.

Pressure system:

Use the motor (about Φ80mmx150mm) to promote the hydraulic pump to apply the vertical force on the test roller;

The motor system can tilt to facilitate sample clamping and installation;

The flexible hydraulic pump piston can compensate the pressure lost in real time during the test due to the friction, and maintain a constant pressure during the test.

Heating system:

Use high temperature resistant stainless steel heating rod as the heat source, providing stable heating and durability;

Large heat sink, with the circulation fan distributes the heat evenly in the test chamber;

Thermocouple with temperature feedback regulation system maintain a constant temperature in the whole test chamber.

Другие товары поставщика

Все товары поставщика

Похожие товары