ACM Series Grinding Machine for Heat Sensitive Materials

The ACM/C series grinders are the result of our latest innovations (Patent Registration No. and are specially designed for grinding heat sensitive materials. The range contains special grinding accessories/devices and features a coarse material re-grind system as well as are-blowing machinism. Specific features of the C series are as follows:

1. Ability to grind brittle materials that are prone to over-grinding, producing a "coarse" (d97>140μm), i.e. blow mesh 100) finished product with consistent granule size and even distribution. Suitable for grinding materials such as polyvinyl alcohol (PVA), with more than 80% of the total amount of retention for the neighbouring three sifting numbers (i.e. sifting meshes 40,60 and 80).

2. Has a re-blowing device, suitable for grinding heat sensitive chemical materials (such as PVA), ensuring that their properties will not deteriorat due to the temperature generated during grinding. This reduces the chance of materials forming spheres caused by high speed spinning and fricton-spherical materials are much harder to grind.

3. The granule size of the product is adjustable by adjusting the gaps between the grinding accessories/devices. The machine is capable of grinding both coarse materials (below mesh 100) and fine materials (above mesh 100).

4. Low cost-priced at less than 30% of similar imported machines.

The machine is suitable for grinding coarse or fine heat sensitive materials, capable of producing consistent granule size. It is therefore widely used in chemical, agro-chemical, foodstuffs, starch andPolyvinyl Alcohol production industries. These machines have demonstrated very stable performance and good reliability as evidenceed by a large number of installations in China's leading vinylon plants, silicon gel plants, and starch processing facilities, having completely replaced similar imported machine.

The machine's main inner linings, whirlwind separator device, dust remover and pipe system are made of either alloyed carbon steel or stainless steel, depending on the specific industry for which the machines to be used.

1. Our design idea is market-oriented and its goal is to increase customers’ satisfaction. Design according to the customers’ special requires. Achieve the perfect combination of rational investment and lower cost.

2. According to related national standard strictly, we guarantee stable and reliable product quality with superb technique and technology.

3. Control the production and examination of the parts and the whole machine strictly.

4. The period of quality guarantee of the equipment is one year, but the whole machine is maintained for whole life. If we receive complaint from customers, we will respond immediately. And if necessary, we will send someone to the field at once.

5. When technical breakthrough and improvement happen, we will do the correction and upgrade for customers with cost price only if customers will.

6. Supply the blueprint of the product line and equipment details for free.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Ring Roller Grinding Mill for all kind of Nonmetallic Ore | The ring roller mill is our self-developed patent product (Patent Number: ZL02270593.7), by impact, extrusion, grinding and other principles of... | |

| MT Series Ring Roller Mill for Making Superfine Powder | The ring roller mill is our self-developed patent product (Patent Number: ZL02270593.7), by impact, extrusion, grinding and other principles of the... | |

| ACMX-935B Nano Powder Mill Scattered Depolymerization | TheACMX-935BserieswasupgradedtypefromACM/Bseries, whicharehighlyefficientsuper-finepunch-action mechanical micro grindingmachinescapableofperform... | |

| ACM Series Ultrafine Impact Mill for Chemical Mineral Food Industries | The ACM/A series are highly efficient super-fine punch-action mechanical micro grinding machines of performing the complete process of material gr... | |

| OEM Custom make Iron Casting Elevator Traction Hub | 1.Material:different grades of gray iron, ductile iron. 2.Standard:ASTMDINBSJISGB. 3.Surface finish:shot blasting,painting,etc. 4.Weight: 5-500kg. ... |

Похожие товары

| 3 Inch Ceramic Bond Hybird Transitional Polishing Pads For Concrete | Продавец: Xiamen ChinShine Industry and Trade Corporation | – Available Grits: 30, 50, 100, 200,400. – Use wet or dry. Pad Materials –... | |

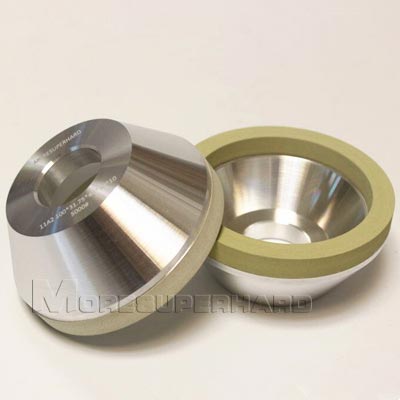

| 11A2 Стеклокерамический алмазный круг для шлифования инструментов PCD | Продавец: Henan Moao superhard material | Применение стеклокерамического алмазного круга для Pcd Специально для черновой, средней, получист... | |

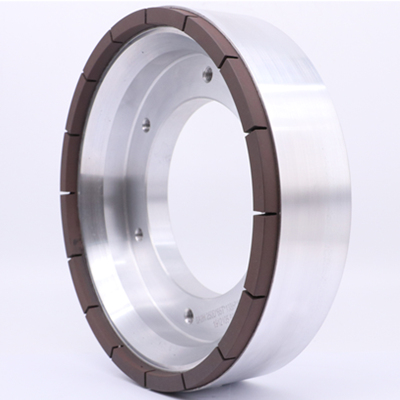

| Колеса из смолы для стекла | Продавец: Henan Moao superhard material | Применяемые машины алмазных кругов по смоле Станок для обработки прямой кромки стекла, станок для... | |

| Dental milling burs | Продавец: Jinrui (Гуандун) Новые материалы Co., Ltd. | Product Advantages: Good wear resistance. 2. Complete product range, suitable for all kinds of... | |

| Карбонит-режущее колесо, связывающее смолу | Продавец: Хэнань Моre Superhard матэрыялы Лтд | Карбонит-связыватель (лезвие для резки) обладает свойствами вертикальных потерь, которые эффектив... |