INJECTION MOLDING SERVICES

LC Rapid is an expert in advanced technology when it comes to plastic injection molding. With advanced technology, high quality plastic material, good quality control process, decades of manufacturing experience and a team of experienced project managers, we can ensure exceptional quality tools and parts that exceed your expectations being delivered on time. We can produce 25 to 100,000+ parts. We embrace advanced technology and cost reduction measure to guarantee our competitiveness in the global market. Just upload your product design and request information to complete your project.

Introduction of Injection Molding Services

The Plastic injection molding is a manufacturing process that requires an injection molding machine, raw plastic resin, an injection mold tools.

The injection molding process consists of the following key steps.

Step 1: The plastic resin begins as raw plastic pellets. These have been treated by drying, and then if necessary dyeing with pigments or master batch colorants.

Step 2: The pallets is fed into the machine through a funnel-shaped hopper. A reciprocating screw inside the barrel of the machine will inject these resins into the mold’s runner system.

Step 3 : Resin pallets are loaded into a heated and compressed chamber called the barrel where they will be melted, forming the liquid resin.

Step 4: The melted resin enters into the mold cavity through a nozzle under high pressure.

Step 5: After the mold’s cooling and solidification, the part has been demoulded to the shape of the mold cavity.

Step 6: The mold halves (cavity or “A” side and core or “B” side) open up and a cycle begins again for the next part.

Advantages of Plastic Injection Molding

Good FinishesGood Finishes

Injection Molding delivers the superior appearance, quality, and surface finish when compared with many other manufacturing processes.

Cost EfficientCost Efficient

The price-per-piece is significantly lower when compared with other processes. The final cost correlates with product quantity – greater quantities mean overall price decreases.

Time EfficientTime Efficient

We offer full lines of manufacturing and finishing services to make tools, allowing us to deliver superior quality molded parts within 10 days.

Wide Range of Material SelectionWide Range of Material Selection

Choose from near-limitless plastic materials, Injection Molding produces high production runs of parts from a wide array of certified materials.

ScalabilityScalability

Plastic Injection Molding is the perfect process for custom production 25-100,000 parts.

High TolerancesHigh Tolerances

Injection Molding is a highly automated production process that produce hundreds of thousands of finished identical parts with very details and accuracy dimension.

Injection Molding Process

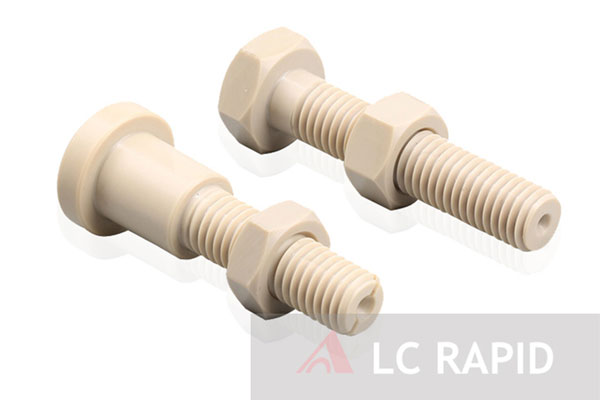

Insert Molding

Insert molding is a great injection molding process that combine metal and plastics into one single part. It allows inserts such as helicoils, screws, metal filters to go inside your mold.

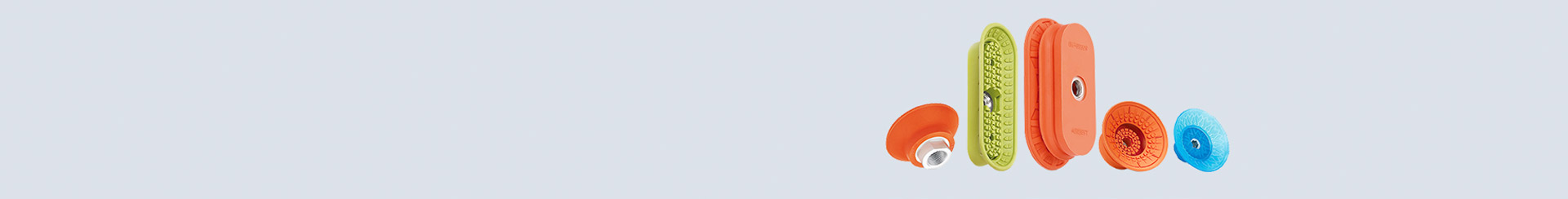

Overmolding

The overmolding is a multi-material injection molding process that allows clients to get the final item that involves two or more different types of material.

Mold Making

We offer design and manufacturing services for mold, dies, and tools to produce high quality plastic parts. Clients owe the tools.

Thermoplastic Injection Molding

LC Rapid produce custom injection molded items from hard toolings for low production volumes and large production runs.

Injection Molding Tolerance

The tolerance depends on the injection plastic, tooling structure, and the design geometry, injection molding part tolerance need to be discussed every project, we will attempt to meet your tolerance standard.

Injection Molding Material

|

Material |

Abbreviation |

|

Acrylonitrile Butadiene Styrene |

ABS |

|

Polypropylene |

PP |

|

Polyoxymethylene |

POM |

|

Polycarbonate |

PC |

|

Polycarbonate-Acrylonitrile Butadiene Styrene |

PC-ABS |

|

Polyvinyl Chloride (Shore D) |

PVC |

|

Polyamide |

Nylon (PA) |

|

Polymethyl Methacrylate |

Acrylic (PMMA) |

|

Polystyrene |

PS |

|

Polyetherimide |

PEI |

Injection Molding Finishes

|

Surface Finish |

Guide |

Typical Applications |

|

SPI A-1 |

Grade #3 diamond buff |

High polish parts, optically clear. |

|

SPI A-2 |

Grade #6 diamond buff |

High polish parts. |

|

SPI A-3 |

Grade #15 diamond buff |

High polish parts. |

|

SPI B-1 |

600 Grit Paper. |

Medium polish parts. |

|

SPI B-2 |

400 Grit Paper. |

Medium polish parts. |

|

SPI B-3 |

320 Grit Paper |

Medium- Low polish parts. |

|

SPI C-1 |

600 Stone. |

Low polish parts. |

|

SPI C-2 |

400 Stone. |

Low polish parts. |

|

SPI C-3 |

320 Stone. |

Low polish parts. |

|

SPI D-1 |

Dry Blast Glass Bead |

Satin Finish. |

|

SPI D-2 |

Dry Blast #240 Aluminum Oxide |

Dull Finish. |

|

SPI D-3 |

Dry Blast #24 Aluminum Oxide |

Dull Finish. |

|

Standard No Machine Mark |

Remove tooling marks |

Low Cosmetic |

|

Mold Texturing |

We can match a wide varieties of mold textures upon request. |

We are one of the best injection molding companies,as a injection mold inc,we have precision plastic injection molding,preform injection molding,low volume plastic molding,prototype molding services,rapid moulding,low volume plastic injection moldingand carbon fiber composite,contact us now.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Electronic Communication | Electronic communication devices encompass an impressive array of goods that make our daily life easier and more convenient. Many of these products... | |

| Medical | In no industry is high quality, precision, and safety more critical than the medical industry. At LC Rapid, we utilize our massive range of custom ... | |

| Medical | We are a leading diversified industrial manufacturer of high-quality customized metal and plastic parts. We have been providing high precision rapi... | |

| 3D PRINTING SERVICES | LC Rapid 3d printing fabrication companiesthat has advanced 3D printers. We are the expert to help you find suitable 3d printing solutions to make ... | |

| Automotive | LC Rapid is determined to offer customers with efficient and cost-saving way to manufacture tangible models that tailor to your design ideas &ndash... |

Похожие товары

| Natural Rubber Suction Cups | Продавец: AIR BEST(CHANGXING)TECHNOLOGY CO., LTD. | Excellent wear resistance BRIEF INTRODUCTION OF NATURAL RUBBER SUCTION CUPS AIRBEST rubber va... | |

| High Temp Silicone Suction Cups | Продавец: AIR BEST(CHANGXING)TECHNOLOGY CO., LTD. | High-temperature resistance Excellent weather and ozone resistance BRIEF INTRODUCTION OF HIGH T... | |

| Fluorine Rubber Suction Cups | Продавец: AIR BEST(CHANGXING)TECHNOLOGY CO., LTD. | BRIEF INTRODUCTION OF FLUORINE RUBBER SUCTION CUPS AIRBEST small rubber suction pads, small rubb... | |

| Conductive silicone Suction Cups | Продавец: AIR BEST(CHANGXING)TECHNOLOGY CO., LTD. | BRIEF INTRODUCTION OF CONDUCTIVE SILICONE SUCTION CUPS Excellent weather and ozone resistanceSof... | |

| Suction Cups In Tile & Marble | Продавец: AIR BEST(CHANGXING)TECHNOLOGY CO., LTD. | BRIEF INTRODUCTION OF SUCTION CUPS IN TILE & MARBLE AIRBEST suction cups for textured tilear... |