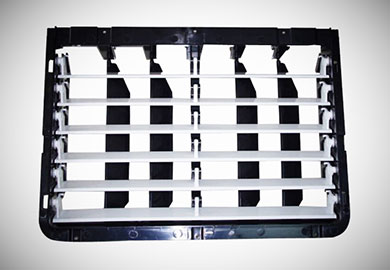

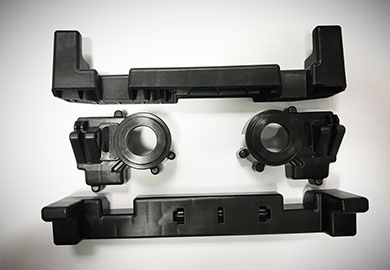

Home Appliance Part

Home Appliance Part

The development and design of plastic injection molding home appliance parts pay attention to safety and health. In-home appliance industry, polypropylene plastics are used extensively in washing machines and dishwashers.

As one of the leading plastic injection moulding productsmanufacturers, our home appliance parts mold injection provides you with high-quality service. Plastic injection molding home appliance products play an important role in daily life for all the home appliances in everyday use such as sitting on a chair while we have a meal.

Features of Home Appliance Part

Here are three major features of injection moulding home appliance products as follows.

High-speed machining technology is widely used

High-speed machining, usually used for large-scale home appliance plastic molded parts and its precision injection molding surface can reach 0.01mm.

High-speed scanner and mold scanning system

High-speed scanner and mold scanning system provide many functions required for plastic injection moulding home appliance parts model which will shorten manufacturing cycle of home appliance products made by injection molding.

Combination of rapid prototyping and tooling technology

Injection mold design for parts of the home appliance is quickly manufactured based on the prototype with the rapid prototyping and tooling technology.

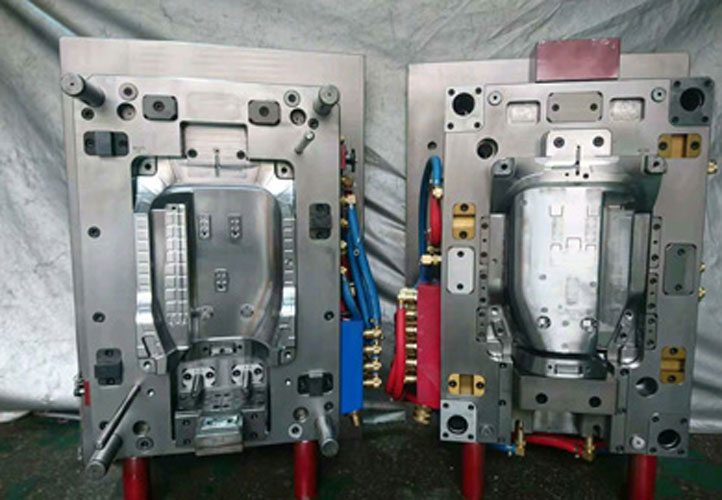

The Specification of Home Appliance Part

|

Part material |

PBT |

|

Mould Cavity |

1 |

|

Mould steel |

H13 |

|

Mould steel |

|

|

Tooling life |

100W |

|

Mould standard |

DME |

|

Exporting country |

USA |

|

Leadtime |

5 weeks |

|

Customer satisfaction with mold quality |

96% |

|

FAI pass rate |

99% |

|

Customer satisfaction with project cooperation service |

98% |

How does Injection Molding Home Appliance Parts Work?

Before we talk about the specific parameters of custom plastic injection moldinghome appliance parts, how do injection molding home appliance parts actually work?

Step 1: Feeding and heating the plastic

At first, a thermoplastic or combination of thermoplastics is put into a precision injection molding machine.

Step 2: Plastic injection

As long as the clamp pressure of the injection molding part is in the best state, the plastic is injected at high speed and pressure into the cavity.

Step 3: Forming the part

Once the tool cavity is almost full of liquid, a holding phase starts to work during the process of home appliance products made by injection molding.

If you want to know more about appliance plastic injection molding, please visit our website.

We offer high quality mold tech chinafor clients, if you have needs, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| CNC Components | We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sale... | |

| Electronics Product Part | Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injectio... | |

| Electronics Product Part | Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronicsis much higher. The injectio... | |

| Mould Slide | Mould Slide The mould slideris a mold component that can slide in a certain angle perpendicular to or with the opening and closing direction dur... | |

| CNC Components | GM-TECH, injection moulding manufacturers,has been manufacturing tools for injection molding of plastics for various industries for more than 10 ye... |

Похожие товары

| Zbk03 Series Roots Vacuum Pump/Roots Pump | Продавец: Greentech International (Zhangqiu) Co., Ltd | ZBK series roots vacuum pump is a kind of coarse vacuum acquisition of equipment, it is widely us... | |

| Quick-response Mechanical seal M74N-140 for power generation | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Quick-response Mechanical seal M74N-140 for power generation Is YOYIK for the use of turbine uni... | |

| "High-reliability Support ring Y10-4 for power station | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-reliability Support ring Y10-4 for power station Deyang YOYIK have power plant professional... | |

| "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "Wear Resistance dn50 globe valve WJ25-F1.6P for thermal power plant YOYIK professional productio... | |

| High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "High-efficiency Superheater outlet plug valve SD61H-P61305V SA-182 F92 for power generation Deya... |